In our foundry operations specializing in large-scale valve components for nuclear and marine systems, we consistently confront the challenge of blow hole defects during the casting of super duplex stainless steel (SDSS) butterfly valve bodies, specifically those made from grade 00Cr25Ni7Mo4N (SAF 2507). These defects, particularly prevalent in large sections like DN1050 valve bodies with significant thickness variations, critically compromise pressure integrity and corrosion resistance. This paper details our comprehensive investigation into the root causes of these blow hole defects and the effective countermeasures we developed and implemented.

Blow hole defects manifest in various forms within the cast valve bodies and are broadly categorized based on their formation mechanism:

- Invasive Blow Hole Defects: Formed when gases generated external to the molten metal (primarily from the mold/core) invade the solidifying metal. The fundamental pressure balance governing their formation is expressed as:

$$P_{gas} < P_{metal} + P_{res} + P_{cav}$$

Where \(P_{gas}\) is the gas pressure at the metal/mold interface, \(P_{metal}\) is the metallostatic pressure, \(P_{res}\) is the resistance pressure due to metal viscosity and surface tension, and \(P_{cav}\) is the pressure within existing cavities. Violation of this inequality leads to gas entrainment and blow hole defect formation. Phenolic urethane resin sand, while offering advantages, generates significant gas volumes (approximately 460 ml/g) predominantly within the 650°C to 750°C range. Environmental humidity drastically exacerbates this issue, as absorbed moisture decomposes at high temperatures, contributing substantially to \(P_{gas}\). - Reaction-Induced Blow Hole Defects: Result from chemical reactions occurring either between the molten metal and the mold atmosphere/gases or within the metal melt itself. Common reactions involve dissolved gases (like Hydrogen and Nitrogen in SDSS) precipitating out during solidification, or slag/metal reactions forming gaseous products. Poor slag control during melting is a major contributor.

- Precipitated Blow Hole Defects: Caused by the decreasing solubility of gases (H₂, N₂) dissolved in the molten SDSS alloy as it cools and solidifies. While less dominant in the observed large blow hole defects, they contribute to micro-porosity.

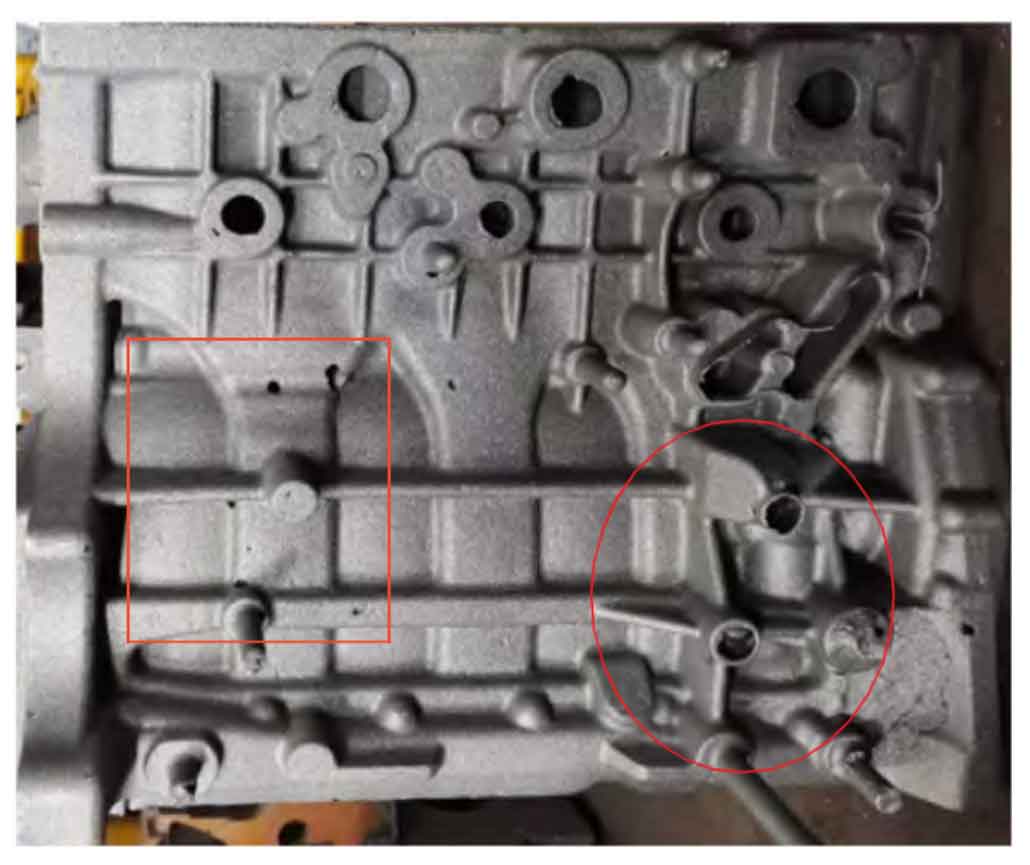

Characterizing the blow hole defect type is crucial for implementing the correct remedy. In our SAF 2507 valve bodies, we observed distinct morphologies:

Scanning Electron Microscopy (SEM) analysis of blow hole defect surfaces revealed characteristic vein-like textures, indicative of gas/metal interaction during formation. Crucially, Energy Dispersive Spectroscopy (EDS) identified significant concentrations of Oxygen and Aluminum within slag inclusions present on the blow hole defect surfaces (Table 1), pointing towards deoxidation products (Al₂O₃) being entrapped during gas evolution, confirming a reaction mechanism intertwined with slag entrapment.

| Element | Weight % (Wt%) | Atomic % (At%) |

|---|---|---|

| C | 2.70 | 10.93 |

| O | 11.10 | 3.34 |

| Al | 3.19 | 5.74 |

| Si | 2.33 | 4.02 |

| Mo | 6.55 | 5.84 |

| Cr | 24.70 | 23.05 |

| Fe | 44.01 | 42.59 |

| Ni | 5.42 | 4.48 |

Our root cause analysis identified several interacting factors contributing to the pervasive blow hole defect issue:

- Mold Sand Characteristics & Environmental Control:

- The alkaline phenolic urethane resin binder system, essential for large core stability, has high total gas generation (460 ml/g) and a broad decomposition range (650-750°C), increasing the period of high \(P_{gas}\) risk.

- High ambient humidity (>20g/m³) significantly increases moisture absorption in both virgin and reclaimed sand. During pouring, this moisture decomposes: $$H_2O \rightarrow H_2 + \frac{1}{2}O_2$$ generating substantial hydrogen gas, dramatically increasing \(P_{gas}\) and the likelihood of invasive blow hole defect formation.

- Inadequate venting design in complex core assemblies impeded gas escape.

- Charge Material & Melting Practice:

- Excessive use of high-oxygen, high-moisture reclaimed scrap (>30%) introduced dissolved hydrogen and oxides, acting as nuclei for blow hole defect growth.

- Conventional slag formers (e.g., Fluorspar – CaF₂) lacked sufficient deoxidizing and degassing power for the highly reactive SAF 2507 melt. Inefficient slag removal left inclusions that facilitated reaction blow hole defect formation.

- Inconsistent melt superheat temperature affected gas solubility and slag fluidity/viscosity, impacting inclusion removal efficiency. The relationship between temperature (\(T\)) and hydrogen solubility (\(S_H\)) follows Sievert’s law: $$S_H = K_H \sqrt{P_{H_2}}$$ where \(K_H\) is the temperature-dependent solubility constant.

- Pouring Parameters:

- Suboptimal pouring temperature exacerbated both invasive and reaction blow hole defects. Low temperatures increased metal viscosity (\(P_{res}\)), hindering gas bubble escape. High temperatures increased gas solubility during pour but promoted more severe reaction kinetics and potentially larger shrinkage porosity. We established the target range as 1590°C – 1650°C, factoring in heat loss: $$\Delta T_{loss} = k \cdot t$$ where \(k \approx 6.4 ^\circ C/min\) for a 1-ton ladle, and \(t\) is transfer/pouring time (~10 min).

To systematically eliminate the blow hole defect, we implemented a multi-faceted strategy targeting each identified root cause:

- Strict Control of Sand Properties & Environment:

- Implemented real-time monitoring of virgin and reclaimed sand temperature (\(T_s\)) and moisture content (\(M_s\)). Defined strict control windows: \(T_s = 20 \pm 5^\circ C\), \(M_s < 0.3\%\).

- Developed dynamic adjustments to resin and hardener ratios based on ambient conditions (Table 2).

- Employed low-temperature hardeners for operations below 10°C.

- Redesigned cores to be hollow, significantly improving permeability and providing space for core sand expansion/gas venting, directly reducing \(P_{gas}\) buildup.

- Added explicit vent channels and increased venting capacity at the mold cope, particularly above thick sections and near feeders.

- Optimized Charge Makeup, Slag Control & Degassing:

- Limited reclaimed scrap usage to ≤ 30%, ensuring ≥ 70% virgin low-oxygen raw materials (FeCr, FeNi, FeMo, ferro-alloys) to minimize initial hydrogen and oxide load.

- Replaced Fluorspar with a specialized stainless steel slag conditioner/deoxidizer possessing high capacity for oxide absorption and hydrogen removal via chemical reaction (e.g., $$Al + 3H \rightarrow AlH_3 \uparrow$$ or similar mechanisms within the slag).

- Implemented a strict slag removal protocol: Achieve superheat (1670-1700°C), power off for 2 minutes allowing slag agglomeration/floatation, apply specialized conditioner, then thoroughly remove slag *before* final temperature adjustment and tapping.

- Optimized Argon purging parameters (flow rate, lance depth, duration) for enhanced hydrogen removal: $$[H]_final = [H]_initial \cdot e^{-k \cdot t}$$ where \(k\) depends on purge efficiency.

- Precise Pouring Temperature Management:

- Calibrated furnace/ladle thermocouples and implemented strict temperature logging.

- Set target tap temperature (\(T_{tap}\)) based on the established pouring range (\(T_{pour} = 1590-1650^\circ C\)) and known transfer losses: $$T_{tap} = T_{pour}^{target} + \Delta T_{loss} + \Delta T_{safety}$$ Typically resulting in \(T_{tap} \approx 1680-1700^\circ C\).

- Minimized transfer time (< 8 minutes) through optimized logistics.

| Environmental Change | Hardener Adjustment | Rationale |

|---|---|---|

| Temperature ↑ 10°C | ↓ 0.5% – 1.0% | Accelerated curing rate (doubles per 10°C rise) |

| Temperature ↓ 10°C | ↑ 0.5% – 1.0% | Slowed curing rate |

| Humidity ↑ (e.g., >20g/m³) | ↑ Slightly (0.2-0.5%) | Counteract moisture inhibition of cure; reduce moisture-induced gas |

| Temperature < 10°C | Switch to Low-Temp Hardener | Ensure adequate curing kinetics at low temperature |

The implementation of these integrated measures yielded significant improvements in valve body quality regarding blow hole defect elimination. Rigorous X-ray and ultrasonic inspection revealed a dramatic reduction in both large invasive blow hole defects near the cope surface and internal reaction-induced blow hole defects associated with slag. The overall casting rejection rate due to gas-related defects decreased from over 15% to below 2%. Crucially, pressure testing success rates on finished DN1050 valve bodies manufactured using the optimized process consistently exceeded 98%, meeting stringent nuclear coolant system specifications. The enhanced process stability also reduced reliance on extensive weld repair, lowering manufacturing costs significantly. Continuous monitoring of sand parameters, melt practice, and pouring temperatures remains essential for preventing the recurrence of these detrimental blow hole defects.

Effectively mitigating blow hole defects in large, complex super duplex stainless steel castings like seawater valve bodies requires a holistic approach. It is not sufficient to address only mold gases or only melt cleanliness; both invasive and reaction mechanisms must be tackled simultaneously. Our experience demonstrates that stringent control of the sand system environment (temperature, humidity), precise adjustment of binder chemistry, optimization of charge materials, utilization of specialized powerful slag conditioners/deoxidizers, strict slag removal protocols, and meticulous management of melting and pouring temperatures are all critical elements. The successful elimination of the blow hole defect significantly enhances the pressure integrity, corrosion resistance, and overall reliability of these critical components in demanding seawater and nuclear applications.