The increasing global emphasis on health and fitness, significantly bolstered by major sporting events, has driven a surge in demand for both home and commercial sports equipment. This demand extends to equipment ranging from simple dumbbells to complex gym machinery. Consequently, the quality requirements for the metallic components of this equipment have intensified. These components must exhibit a tailored combination of properties: high strength-to-weight ratio, excellent fatigue resistance, good ductility or toughness, and often, superior corrosion resistance. A significant portion of sports equipment relies on high-performance alloy castings. Therefore, enhancing the quality of these castings by mitigating common foundry defects is paramount for manufacturing superior, safer, and more durable sports products.

Among advanced engineering alloys, TiAl-based intermetallic alloys have garnered extensive application across automotive, aerospace, and, increasingly, high-end sports equipment sectors. This popularity stems from their exceptional portfolio of properties: low density, high specific strength and stiffness, good elevated-temperature capabilities, and outstanding corrosion resistance. The inherent biocompatibility of titanium alloys also opens avenues for specialized sports medical devices. Given its prominence, this article focuses on TiAl alloys as the representative material system for investigating quality improvement in sports equipment castings.

In foundry practice, defects such as porosity in casting and hot tearing (a form of cracking) are particularly detrimental. They act as stress concentrators, drastically reducing the fatigue life, dynamic load capacity, and overall structural integrity of a component—critical failures for equipment subjected to repetitive impact or stress. This work, therefore, concentrates on exploring practical methods to avoid porosity in casting and fracture in TiAl alloy castings. We employ systematic experiments, utilizing tools like the PMG-3 optical microscope and the S3700 scanning electron microscope (SEM) for microstructural observation. Through repeated trials involving variations in applied pressure during solidification and mold preheat temperature, we analyze their distinct effects on porosity in casting formation and hot tearing susceptibility, respectively.

Porosity and Hot Tearing in TiAl Alloy Castings

TiAl alloys maintain excellent mechanical properties across a range of temperatures, making them ideal for components requiring reliability under stress. To improve mold filling and density in intricate castings, centrifugal casting techniques are often employed. While effective, this method does not fully immunize the process against inherent defects. The most critical flaws affecting final part performance are porosity in casting and various forms of cracking, with hot tearing being the most prevalent in our context.

The formation of porosity in casting during the solidification of TiAl melt is a complex phenomenon influenced by multiple interacting factors. We can categorize the primary contributors as follows:

- Solidification Cooling Rate: Rapid cooling can trap dissolved gases, while very slow cooling may allow for bubble coalescence and growth.

- Applied External Pressure: This is a crucial processing parameter, especially in pressure-assisted casting techniques.

- Hydrogen Content from Melt Refining: Different degassing and refining practices lead to varying levels of dissolved hydrogen, a major contributor to gas porosity.

In our experimental setup using centrifugal casting under an Argon (Ar) protective atmosphere, factor (2)—the applied pressure—is the principal variable we control. The porosity in casting observed manifests as either surface-connected pores or fully entrapped internal voids. Concurrently, SEM examination of cast TiAl samples reveals cracking defects. Metallic castings can fail via “hot tearing” (occurring in the mushy zone just below the solidus temperature) or “cold cracking” (occurring at much lower temperatures, often post-solidification, related to stresses exceeding the material’s ductile strength). For TiAl castings processed without subsequent rapid quenching, hot tearing is the dominant failure mode. The initiation and propagation of a hot tear involve the formation and growth of a crack nucleus at grain boundaries, fed by inadequate liquid feeding and tensile stresses induced by solidification shrinkage and thermal contraction. Once a critical size is reached, catastrophic failure occurs. Therefore, compared to distributed porosity in casting, preventing hot tearing is often more critical, as a single tear can render a component completely unusable.

Methodologies for Mitigating Defects in TiAl Sports Equipment Castings

Strategies to Reduce Porosity in Casting

As outlined, insufficient applied pressure is a leading cause of porosity in casting in many industrial processes. Empirically, increasing the pressure on the solidifying melt reduces both the number and average size of gas pores. The governing principle is Henry’s Law and the ideal gas law. At a sufficiently high pressure, the solubility of gases like H₂ and Ar in the molten alloy increases, discouraging bubble nucleation and facilitating the dissolution of existing bubbles. If the pressure is too low, nucleated bubbles cannot be compressed or redissolved and instead grow to form stable pores.

The condition for a bubble (pore) to form and grow requires that the internal gas pressure () overcomes the opposing pressures: the external applied pressure () and the metallostatic pressure (), plus the additional pressure due to surface tension (). For a bubble containing hydrogen and argon:

$$

P_{\text{int}} = P_{H_2} + P_{Ar} > P_{\text{ext}} + P_m + \frac{2\sigma}{r}

$$

Assuming the gases behave ideally and the process is isothermal, we have . Therefore, for a given amount of entrapped gas, a lower external pressure () results in a larger bubble volume (), directly linking low pressure to larger porosity in casting.

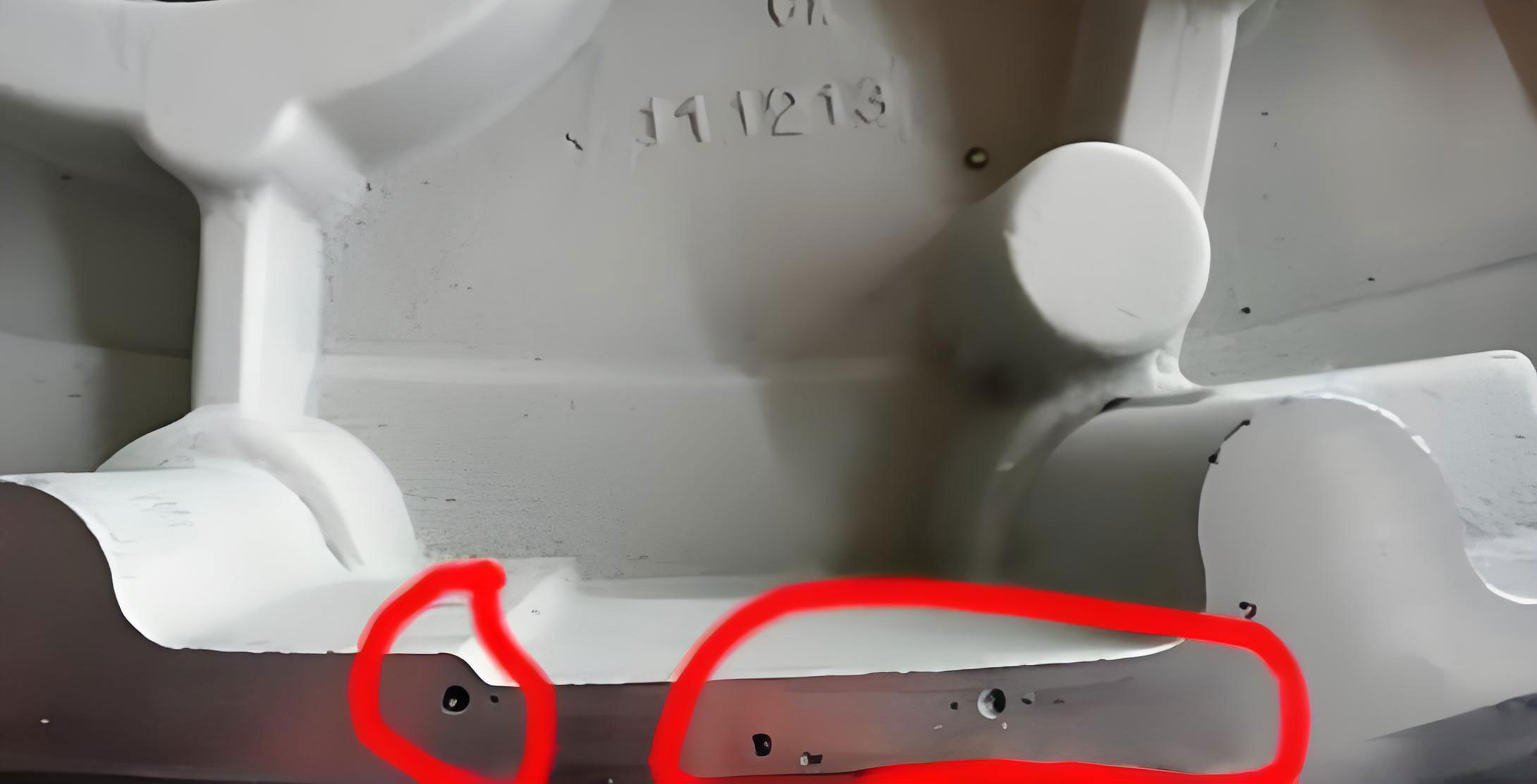

We conducted low-pressure casting experiments on TiAl alloy intended for a sports equipment component. The pressure applied to the melt surface was varied at three levels: 0 MPa (atmospheric), 0.1 MPa, and 0.27 MPa. Cross-sections of the resulting castings were examined under the PMG-3 microscope. The visual comparison is striking and confirms the theoretical prediction.

The microstructural analysis reveals a clear trend: as the applied pressure increases, the prevalence and severity of porosity in casting diminish significantly. This is summarized quantitatively in the table below, which correlates processing pressure with observed pore characteristics.

| Applied Pressure (MPa) | Average Pore Diameter (µm) | Pore Density (pores/mm²) | Qualitative Description of Porosity in Casting |

|---|---|---|---|

| 0.00 | 120 – 250 | 15 – 22 | Severe, large spherical and elongated pores. |

| 0.10 | 40 – 80 | 5 – 10 | Moderate, smaller and more isolated pores. |

| 0.27 | < 20 | 1 – 3 | Minor, very fine and sparse porosity. |

Strategies to Avoid Hot Tearing (Fracture)

Hot tearing is the dominant cracking mechanism during solidification. Its occurrence depends on the competition between strain accumulation in the coherent solid network and the material’s ability to accommodate this strain via liquid feeding or solid deformation. The Hot Tearing Susceptibility (HCS) criterion provides a theoretical framework. It posits that failure occurs when the accumulated tensile strain rate in the vulnerable mushy zone exceeds a critical value, which is a function of the local thermal conditions and material properties.

The critical strain rate limit at the casting surface (where cooling is fastest) can be expressed as related to the pressure build-up required to initiate a tear:

$$

\Delta P_{\text{max}} = \int_{T_s}^{T_{L}} \frac{E(T) f_s(T)}{G [1 – f_s(T)]} \beta \mu V \, dT + \int_{T_{L}}^{T_{L}+\Delta T} \frac{180 \lambda^2 E(T) f_s(T)}{G [1 – f_s(T)]^3} \frac{\beta \mu}{(1-\beta)} V \, dT

$$

Where:

is the elastic modulus,

is the solid fraction,

is the shear modulus,

is the solidification shrinkage,

is the viscosity of the interdendritic liquid,

is the volume, and

is the secondary dendrite arm spacing.

The corresponding critical strain rate at the root of a potential tear is:

$$

\varepsilon_p^{\bullet} = \frac{1}{G} \int E(T) f_s(T) \frac{dT}{dt} \, dT

$$

A simplified form of the HCS criterion, relating the maximum tolerable strain rate to thermal and material parameters, is often used for analysis:

$$

HCS = \frac{1}{\varepsilon_{p,\text{max}}^{\bullet}} = \frac{180 \lambda^2 (1+\beta)}{G F_c(T)} \left[ \frac{1}{\beta \mu V} \Delta P_{\text{max}} – \frac{1}{(1-\beta)} \right]

$$

A key practical variable derived from this model is the mold or casting preheat temperature (). A higher reduces the thermal gradient, lowers the cooling strain rate (), increases the time available for liquid feeding, and can coarsen the dendritic structure (increasing ), all of which contribute to a higher critical strain for tearing (lower HCS value).

We tested TiAl alloy castings under different mold preheat temperatures: 0°C (cold mold), 200°C, and 400°C. The occurrence and severity of hot tearing were documented. The results, viewed under the S3700 SEM to examine crack morphology, strongly support the HCS theory.

| Mold Preheat Temperature (°C) | Hot Tear Observation | Qualitative Severity | Inferred Effect on Critical Strain Rate |

|---|---|---|---|

| 0 | Large, continuous cracks propagating through sections. Component integrity lost. | Catastrophic | Very low critical strain, high HCS. |

| 200 | Small, discontinuous micro-cracks, primarily at grain boundaries. Component may be salvageable with repair. | Moderate | Increased critical strain, reduced HCS. |

| 400 | Very few, isolated incipient tears or none visible at low magnification. No structural compromise. | Minor/None | High critical strain, low HCS. |

The data suggests that increasing the preheat temperature is a highly effective method for suppressing hot tearing. It is plausible that at sufficiently high preheat temperatures, where thermal stresses are minimized, hot tearing could be virtually eliminated for a given casting geometry.

Conclusion

In this investigation, we have systematically addressed the two primary defects plaguing TiAl alloy castings for high-performance sports equipment: porosity in casting and hot tearing. Through controlled experiments and theoretical analysis, we established clear process-property relationships.

For porosity in casting, the external pressure applied during solidification is a dominant controlling factor. Our experimental matrix, analyzed via optical microscopy, demonstrated a powerful inverse correlation: as the applied pressure increased from 0 MPa to 0.1 MPa and further to 0.27 MPa, both the size and population density of gas pores decreased markedly. This is a direct consequence of gas law physics, where higher pressure suppresses bubble nucleation and growth. Implementing adequate pressure-assisted casting techniques is therefore a fundamental and effective strategy for minimizing porosity in casting.

For the more critical defect of hot tearing, the mold preheat temperature emerged as the key process variable. Guided by the Hot Tearing Susceptibility (HCS) criterion, our experiments revealed that a cold mold (0°C preheat) leads to catastrophic cracking, while preheating to 200°C offers significant improvement, and 400°C preheat virtually eliminates the defect in our test geometry. The underlying mechanism involves the reduction of thermal strains and strain rates, allowing the semi-solid material to accommodate contraction stresses without fracture.

In summary, the quality and reliability of TiAl sports equipment castings can be substantially enhanced by a two-pronged approach: optimizing the applied solidification pressure to combat porosity in casting, and optimizing the mold preheat temperature to prevent hot tearing. These findings provide a practical and effective methodology for foundries aiming to produce high-integrity components capable of withstanding the rigorous demands of athletic use. Future work may involve integrating these parameters into multi-variable process optimization models and exploring their interaction with alloy composition modifications for synergistic defect reduction.