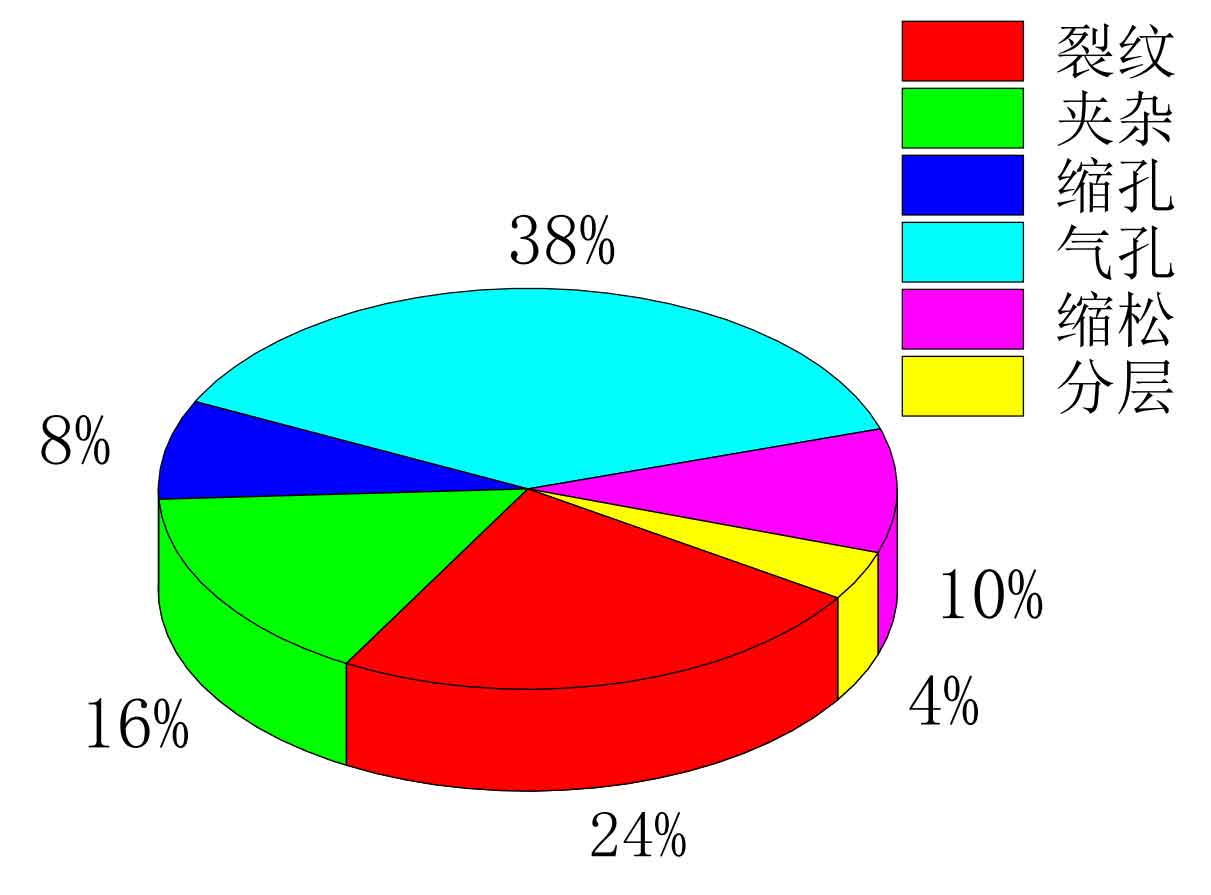

According to the summary, a total of 50 casting defects were found in 24 cast steel joints, and the average number of casting defects per cast steel joint was 2.04. Among the 50 casting defects, there were 12 crack defects, accounting for 24% of all casting defects, 8 inclusion defects, accounting for 16% of all casting defects, 4 shrinkage defects, accounting for 8% of all casting defects, 19 porosity defects, accounting for 36% of all casting defects, and 5 shrinkage defects, It accounts for 10% of all casting defects, and there are 2 delamination defects, accounting for 4% of all casting defects, which shows that air hole defects in cast steel joints are the main casting defects, and the probability of delamination defects is low.

Among the 24 cast steel joints, 21 need to be repaired, and the repair rate has reached 87.5%, which shows that the repair rate of cast steel joints is very high. After the repair is completed, all the joints are found to be qualified by secondary ultrasonic flaw detection.

(1) Cracks occurred in 4 of 24 cast steel joints, accounting for 16.67%; Inclusions appeared in 7 cast steel joints, accounting for 29.17%; Five cast steel joints had shrinkage cavity and porosity defects, accounting for 20.83%; 11 cast steel joints had porosity defects, accounting for 45.83%; Two cast steel joints have delamination defects, accounting for 8.33%; There were 10 cast steel joints with incomplete fusion of core brace, accounting for 41.67%. This shows that the most likely casting defects are porosity defects and core support incomplete fusion defects, followed by inclusions, shrinkage porosity, cracks and delamination.

(2) In terms of the modeling of cast steel joints, cast steel joints are divided into two types: multi pipe intersection joints with R-zone and simple joints. Among the 13 multi tube intersection joints in R zone, 23 casting defects were found, with an average of 1.77 casting defects per node, including 12 cracks, 4 inclusions, 2 shrinkage holes, 5 pores, 0 shrinkage porosity and 0 delamination. Among the cast steel joints with complex shape, the most casting defects are crack defects, followed by pore defects; A total of 27 casting defects were found in 11 simple nodes, with an average of 2.45 casting defects per node, including 0 cracks, 4 inclusions, 2 shrinkage holes, 14 porosity, 5 shrinkage porosity and 2 delamination. The most common casting defects are porosity defects.

It can be found that the cracks appear on the cast steel joints with R zone, and the cast steel joints with simple shape do not have cracks. There are many casting defects in both simple and complex joints.

(3) In terms of the distribution location of casting defects, the location of casting defects is divided into surface defects and internal defects. Among the 50 casting defects, 15 are surface defects and 35 are internal defects, accounting for 72%. The types of surface defects include cracks and pores. There are 12 cracks, accounting for 80%, indicating that cracks occupy the dominant position in surface defects.

To sum up, it can be seen from the analysis that the most common casting defects in cast steel joints are pore defects, and the lack of fusion of core support is a common casting defect in large cast steel joints, which can be seen visually. Casting cracks are very easy to appear on the surface of R zone, which is the blind area of ultrasonic flaw detection of cast steel joints, which should be paid full attention to.