In this study, a new type of Al-Mg-Si alloy without heat treatment was used as the research object, and the numerical simulation and experimental research on the solidification microstructure of the alloy during squeeze casting were carried out. The results show that the established finite element model and CAFE model can accurately predict the solidification process and microstructure of the casting. The solidification sequence of the variable-section casting is from the middle and lower parts to the middle and upper parts, then to the top and finally to the bottom. The shrinkage porosity volume fraction first decreases and then increases with the increase of pouring temperature and mold temperature, and reaches the minimum when the pouring temperature is 700 °C and the mold temperature is 475 °C. The shrinkage porosity volume fraction decreases with the increase of squeeze casting pressure and reaches the minimum at 100 MPa. The microstructure at the bottom and middle and upper parts of the casting is relatively coarse, while that at the middle and lower parts and the top is relatively fine, which is related to the wall thickness and supercooling degree.

1. Introduction

Aluminum alloys are widely used in various industries due to their low density, high specific strength, good corrosion resistance and excellent formability. Among them, the Al-Mg-Si alloy is a kind of heat-treatable alloy, which can obtain high strength and good plasticity through heat treatment. However, the traditional heat treatment process of aluminum alloy has the problems of high energy consumption, long production cycle and easy deformation of parts. In recent years, the non-heat-treated Al-Mg-Si alloy has attracted more and more attention because it can obtain good mechanical properties without heat treatment, which simplifies the production process and reduces the production cost.

Squeeze casting is a casting process that combines casting and forging. It has the advantages of slow filling speed, large solidification pressure, fine grain and good mechanical properties of the casting. At present, numerical simulation technology has been widely used in the research and development of squeeze casting process, which can predict the defects of the casting in advance and optimize the process parameters. However, for the non-heat-treated Al-Mg-Si alloy, the research on the solidification microstructure and defects of the alloy during squeeze casting is relatively few. Therefore, in this study, the numerical simulation and experimental research on the solidification microstructure of the non-heat-treated Al-Mg-Si alloy during squeeze casting were carried out, in order to provide a theoretical basis for the optimization of the squeeze casting process and the improvement of the mechanical properties of the alloy.

2. Experimental Materials and Methods

2.1 Experimental Materials

The experimental alloy is a new type of Al-Mg-Si alloy, and its chemical composition is shown in Table 1. The raw materials used in the experiment include pure aluminum, Al-10Mn, Si, Fe, Zn, Cu, Al-5Ti, Al-4Zr and Al-2Sc.

2.2 Experimental Methods

The alloy was melted in a graphite clay crucible in a resistance furnace at a melting temperature of 750 °C. After the pure aluminum was melted, Al-10Mn, Si, Fe, Zn, Cu, Al-5Ti, Al-4Zr and Al-2Sc were added in turn, and finally the magnesium block wrapped in aluminum foil was added into the melt. After melting for 30 minutes, hexachloroethane was added for melt degassing. When the melt temperature reached the pouring temperature, it was held for 10 minutes and then poured into a preheated metal mold for squeeze casting. After the casting was completely cooled, a 10 mm parallel section sample was taken from the bottom center for rough grinding, fine grinding and polishing, and then etched with a 0.5% hydrofluoric acid (HF) aqueous solution. The microstructure of the alloy was observed by using an optical microscope (Zeiss Axio Observer.Z1m, Germany), a scanning electron microscope (JSM-6301F, Japan) and an EBSD backscattered electron detector equipped with a field emission scanning electron microscope (Zeiss Merlin Compact, Germany).

The shrinkage porosity in the squeeze casting was counted by the following steps:

- The sample was meshed, and the mesh size was 5 mm×5 mm. A two-dimensional coordinate system was established, and the zero point of the coordinate system was set at the intersection of the outer wall extension line and the bottom extension line. The grid coordinates were the center points of each grid.

- All the shrinkage porosity in each grid was photographed by using the BSE mode of the scanning electron microscope, and the total shrinkage porosity area and its proportion in each grid were counted by using ImageProPlus 6.0 software to calculate the shrinkage porosity area fraction in each grid.

- Origin software was used to create a data set of shrinkage porosity area fraction and distribution. The data was converted into a matrix in a meshed manner, and the contour cloud map of shrinkage porosity area fraction and distribution in the casting was made.

3. Numerical Simulation Model

3.1 Macroscopic Numerical Simulation Model

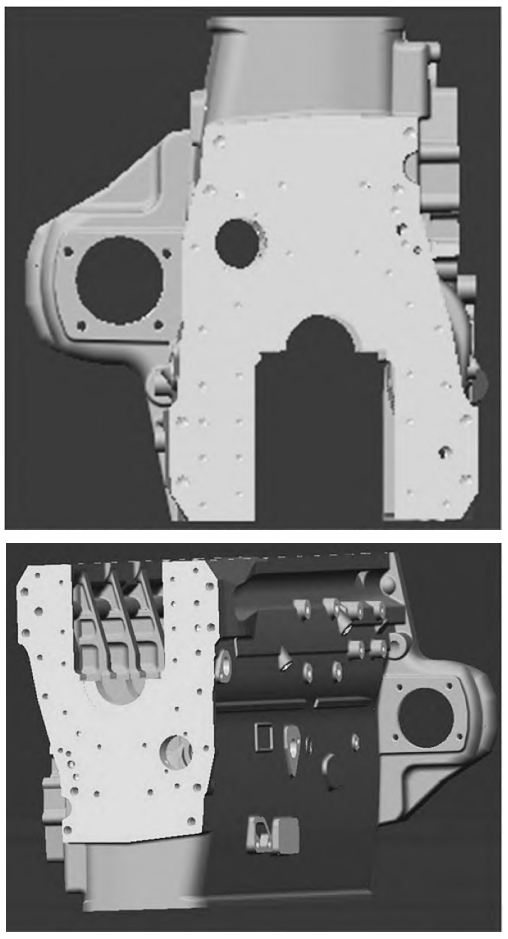

- Physical and geometric model: The three-dimensional model was established by using software, and the solid files of the casting and mold were imported into ProCAST software after the modeling was completed. The unit mesh size of the finite element model was set to 2 mm (casting) and 10 mm (mold), and the final generated volume mesh number was 306422.

- Material parameter calculation: Since there was no relevant data of the alloy brand in the ProCAST software material library, a new material was established and its physical parameters were calculated. Based on the fast cooling rate, the Scheil diffusion model was applicable to the squeeze casting simulation.

- Interface heat transfer coefficient setting: The interface heat transfer coefficient between the mold and the molten metal was set to 2000 W·(m²·K)⁻¹ during the filling stage. During the solidification stage, the heat transfer coefficient was set differently according to the applied pressure, and the relationship between the heat transfer coefficient and the pressure was h = 2000 + 98.4p (where h is the interface heat transfer coefficient in W·(m²·K)⁻¹ and p is the punch pressure in MPa).

- Pressure application: The pressure was applied in the form of the “mold-metal liquid” interface heat transfer coefficient, that is, the thermodynamic effect of the pressure parameter in the squeeze casting process was mainly considered.

- Process condition setting: The punch speed was set to 10 mm·s⁻¹ and the holding time was set to 30 s. The effects of different pouring temperatures, mold temperatures and casting pressures on the squeeze casting process were studied.

- Running parameter setting: The GATEFEED was set to ON to perform the pressure holding and feeding setting, and the PENETRATE was set to ON to activate the interpenetrating mesh algorithm.

3.2 Microscopic Tissue Numerical Simulation Model

- CAFE mathematical model: The CAFE model was selected for the numerical simulation of the solidification microstructure in squeeze casting. The CAFE model was the coupling of the macroscopic temperature field and the microscopic solidification microstructure, that is, the finite element method (FE) and the cellular automaton method (CA) were combined. The nucleation distribution in this model could be described by the Gaussian distribution as follows: dn/d(ΔT) = n_max/ΔT_s exp[-(1/2)((ΔT – ΔT₁)/ΔT_σ)²] (where ΔT is the transient supercooling degree during nucleation in K, ΔT₁ is the average nucleation supercooling degree in K, ΔT_s is the standard deviation of nucleation supercooling degree in K, n_max is the maximum nucleation density in m⁻³).

- CA model establishment:

- Growth kinetic parameter setting: The chemical composition of the alloy in Table 1 was input into the ProCAST software, and the physical parameters were calculated, followed by the calculation of the CAFE parameters. The Gibbs-Thompson coefficient Γ was 2×10⁻⁷, D_t,max was 10, D_t,max (fit) was 10, and the growth kinetic parameters a₂ was 6.0932×10⁻⁷ m·(s·K²)⁻¹ and a₃ was 1.6855×10⁻⁶ m·(s·K²)⁻¹.

- Nucleation parameter setting: The n_s,max and n_v,max were obtained through the experimental metallographic structure and the corresponding mathematical relationship N_V = 0.8N_A^(3/2) = 0.5659N_L³ (where N_v, N_A and N_L represent the number of grains per unit volume, per unit area and per unit length respectively). For the other parameters, they were determined by referring to the microscopic structure diagram obtained from the experiment. The nucleation parameters used in the simulation are shown in Table 2.

4. Results and Discussion

4.1 Filling Process Analysis

The simulation results of the squeeze casting at different filling times with a pouring temperature of 700 °C, a mold temperature of 500 °C and a pressure of 100 MPa are shown in Figure 1. The solidus and liquidus temperatures of the alloy are 585.1 °C and 622.7 °C respectively. The results show that the melt filling process is relatively stable under this process condition, and there are no defects such as air entrainment, indicating that the filling speed design is relatively reasonable.

4.2 Solidification Process Analysis

The simulation results of the solid fraction change at different solidification times with a pouring temperature of 700 °C, a mold temperature of 500 °C and a pressure of 100 MPa are shown in Figure 2. The results show that at the beginning of solidification (2.28 s), the solid fraction in the middle and lower parts (thin-wall area) is relatively high, followed by that in the middle and upper parts, and the solid fractions at the bottom and top are the smallest, corresponding to different solidification sequences. At 4.31 s, the solid fractions at the inner and outer surfaces of the middle and lower parts have reached 0.85, indicating that the first solidified part is the surface of the middle and lower parts, and the corner between the middle and lower parts and the middle and upper parts has solidified, while the core has not solidified, indicating that the thin-thick wall transition area is a region prone to cracks. At 8.15 s, the middle and lower parts are completely solidified, and at this time, the solid fractions at the inner and outer surfaces of the middle and upper parts and the top have reached 0.9, indicating that the second solidified part is the entire side wall surface. At 13.25 s, the side wall is completely solidified and the bottom begins to solidify. At 15.06 s, the top is completely solidified, and then the bottom is completely solidified. At 21.94 s, the bottom is finally solidified. As the top and bottom are the last to solidify, they have a greater tendency to form shrinkage porosity defects. Therefore, the solidification sequence of the variable-section casting is: middle and lower parts – middle and upper parts – top – bottom.

4.3 Influence of Different Process Parameters on Shrinkage Porosity Volume Fraction and Distribution

- Macroscopic model verification: The shrinkage porosity distribution cloud maps of the casting under the conditions of a mold temperature of 475 °C, a pouring temperature of 660 °C and a pressure of 100 MPa are shown in Figure 3. The results show that the positions of shrinkage porosity in the simulation and experimental results are relatively consistent (at the top), indicating that the established macroscopic finite element model for squeeze casting in this paper is relatively reasonable.

- Influence of pouring temperature on shrinkage porosity volume fraction and distribution: The simulation results of shrinkage porosity volume fraction and distribution under different pouring temperatures with a mold temperature of 475 °C and a pressure of 100 MPa are shown in Figure 4, and the shrinkage porosity volume fractions at different pouring temperatures are shown in Figure 5. The results show that the shrinkage porosity is mainly distributed at the bottom and top of the casting. With the increase of pouring temperature, the shrinkage porosity volume fraction first decreases and then increases, and the shrinkage porosity volume fraction is the smallest at a pouring temperature of 700 °C. The formation of shrinkage porosity is affected by two main factors, one is the feeding ability of the melt, and the other is the density difference between the liquid and solid phases. When the pouring temperature is 660 °C, due to the relatively high viscosity of the alloy melt, the feeding ability of the melt between dendrites is relatively weak, so the shrinkage porosity volume fraction of the casting is relatively large. When the pouring temperature is 740 °C, although the melt viscosity decreases, the melt density increases significantly with the increase of temperature, and the density difference between the two phases is more significant, and the tendency to form shrinkage porosity is obvious, so the shrinkage porosity volume fraction in the casting is relatively large. When the pouring temperature is 700 °C, it not only retains a good melt feeding ability, but also the density difference between the solid and liquid phases is not too large, so the shrinkage porosity volume fraction is the smallest.

- Influence of mold temperature on shrinkage porosity volume fraction and distribution: The simulation results of shrinkage porosity volume fraction and distribution under different mold temperatures with a pouring temperature of 700 °C and a pressure of 100 MPa are shown in Figure 6, and the shrinkage porosity volume fractions at different mold temperatures are shown in Figure 7. The results show that with the increase of mold temperature, the shrinkage porosity volume fraction first decreases and then increases, and the shrinkage porosity volume fraction is the smallest at a mold temperature of 475 °C. For the squeeze casting process, the influence of mold temperature on shrinkage porosity mainly comes from the change of solidification speed. When the mold temperature is low, the solidification speed is fast, and the molten metal poured into the mold quickly forms a solid shell, and the effect of pressure is not fully reflected. Under the condition of a mold temperature of 450 °C, the shrinkage porosity volume fraction in the casting is relatively large. With the increase of mold temperature, the solidification time is longer under the action of pressure, and the positive effect of pressure on feeding is better reflected. Under the condition of a mold temperature of 475 °C, the shrinkage porosity volume fraction decreases. When the temperature is too high, the volume fraction of entrapped gas also increases, which aggravates the formation of shrinkage porosity. Under the condition of a mold temperature of 500 °C, the shrinkage porosity volume fraction increases. It should be noted that due to the small size of the casting, a higher mold temperature is adopted to achieve the squeeze casting of a small amount of melt. In the actual squeeze casting production, with the increase of casting size, the mold temperature can be appropriately reduced, but the internal mechanism and overall trend of the influence of mold temperature on shrinkage porosity are consistent.

- Influence of pressure on shrinkage porosity volume fraction and distribution: The simulation results of shrinkage porosity volume fraction and distribution under different pressure conditions with a pouring temperature of 720 °C and a mold temperature of 500 °C are shown in Figure 8, and the variation curve of shrinkage porosity volume fraction under different pressures is shown in Figure 9. The results show that with the increase of pressure, the shrinkage porosity volume fraction decreases, and the shrinkage porosity volume fraction is the smallest at a pressure of 100 MPa. In the squeeze casting process, on the one hand, the pressure improves the feeding of the melt, and on the other hand, it promotes the healing of shrinkage porosity by generating plastic deformation locally, thus significantly reducing shrinkage porosity. In addition, the pressure in the squeeze casting process improves the heat transfer between the melt and the mold wall, which is beneficial to refining the solidification microstructure and also reduces the tendency to form shrinkage porosity.

4.4 Grain Structure Simulation Results

- CA model verification: The simulation results (grain structure) and experimental results (metallographic structure) of the squeeze casting cup-shaped casting under the conditions of a pouring temperature of 700 °C, a mold temperature of 450 °C and a pressure of 100 MPa are shown in Figure 10. It can be seen from Figure 10(a) that the grain structures at the bottom and middle and upper parts of the casting are relatively coarse, while those at the middle and lower parts and the top are relatively fine. It can be seen from Figure 10(b) that the overall grain structure distribution in the casting in the experimental results is relatively consistent with that in the simulation results, indicating that the established CA model for grain growth in squeeze casting in this paper is relatively reasonable. The formation of the grain structure includes nucleation and growth, and is mainly affected by the melt supercooling degree and cooling rate in the process. For squeeze casting, the grain structures at the bottom and middle and upper parts of the casting are coarse because of their large wall thickness, slow melt cooling rate and small supercooling degree. The structure in the middle and lower parts is fine because of its small wall thickness. The grain structure at the top is relatively fine because of its large wall thickness and good heat dissipation conditions in contact with the thick convex mold end cover.

- Influence of pouring temperature and mold temperature on grain structure: The simulation results of the grain structure at position 1 in Figure 10 under different pouring temperature conditions with a pressure of 100 MPa are shown in Figure 11, and the simulation results of the grain structure under different mold temperature conditions are shown in Figure 12. It can be seen from Figures 11 and 12 that with the increase of pouring temperature and mold temperature, the average grain size increases, but the increase is relatively small. In the squeeze casting process, the higher the pouring temperature and mold temperature, the smaller the supercooling degree, the lower the nucleation rate, and at the same time, due to the longer solidification time, the grains grow more fully, so the grain structure of the alloy is coarser.

4.4 Grain Structure Simulation Results (Continued)

The simulation results of the grain structure at position 1 in Figure 10 under different pressure conditions with a pouring temperature of 720 °C and a mold temperature of 500 °C are shown in Figure 13. It can be seen that with the increase of pressure, the average grain size decreases and the grain structure is refined significantly. The EBSD images of the grain structure of the casting under different pressure conditions are shown in Figure 14. It can be seen from Figure 14 that with the increase of pressure, the average grain size decreases, and the trends obtained in the experimental and simulation results are relatively consistent. In the squeeze casting process, the pressure can significantly improve the heat transfer between the melt and the metal mold, increase the cooling rate, which is beneficial to increase the nucleation rate in the metal melt and shorten the dendrite growth time, so as to obtain a refined solidification structure. The greater the pressure, the more obvious this effect is. Therefore, the grain structure is refined most obviously under the pressure condition of 100 MPa. This result is also consistent with the experimental results of the Al-Si alloy squeeze casting.

5. Conclusion

- The finite element physical and geometric model and the grain growth CA model for the squeeze casting of the variable-section cup-shaped part were established, and the filling process, shrinkage porosity distribution and grain structure simulation of the new Al-Mg-Si alloy squeeze casting were realized.

- The solidification sequence of the Al-Mg-Si aluminum alloy variable-section casting in squeeze casting is: middle and lower parts – middle and upper parts – top – bottom.

- With the increase of pouring temperature and mold temperature, the shrinkage porosity volume fraction first decreases and then increases; with the increase of pressure, the shrinkage porosity volume fraction decreases.

- The microstructure at the bottom and middle and upper parts of the casting is relatively coarse, while that at the middle and lower parts and the top is relatively fine, which is related to the wall thickness and supercooling degree.