According to GB9441-2009 metallographic inspection standard for nodular cast iron, the pearlite content in the as cast matrix is graded.

Through comparison, it is found that under the as cast condition of nodular cast iron, the pearlescent volume of A7 is the least, about 5%. B4 has the largest pearlescent volume, reaching about 75%.

The data show that the matrix of nodular cast iron is mostly the mixed structure of pearlite and ferrite, and all the matrix is transformed into ferrite after heat treatment. By observing the metallographic photos, it can be seen that there is a certain amount of pearlite in the matrix of the single cast sample in the as cast state, and only the B2 attached cast sample is all ferrite. After heat treatment, the matrix of the sample is ferrite.

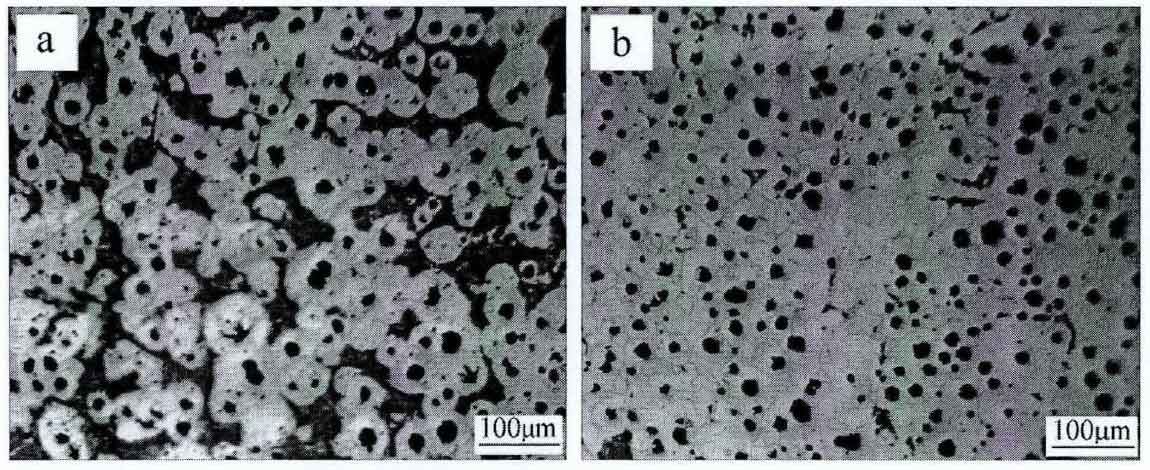

In terms of chemical composition, the addition of secret and copper has an obvious effect on the matrix structure. Figure 1 shows the effect of bismuth on the matrix.

It can be seen from the figure that when bismuth is not added, the pearlite content of A5 is 35%, as shown in Figure 1a. When 0.006% bismuth was added, the pearlite content of A7 decreased to 5%, as shown in Fig. 1b. It can be seen that with the addition of bismuth, the content of pearlite decreases and the content of ferrite increases. While refining graphite spheres, it also plays a role in promoting the formation of ferrite.

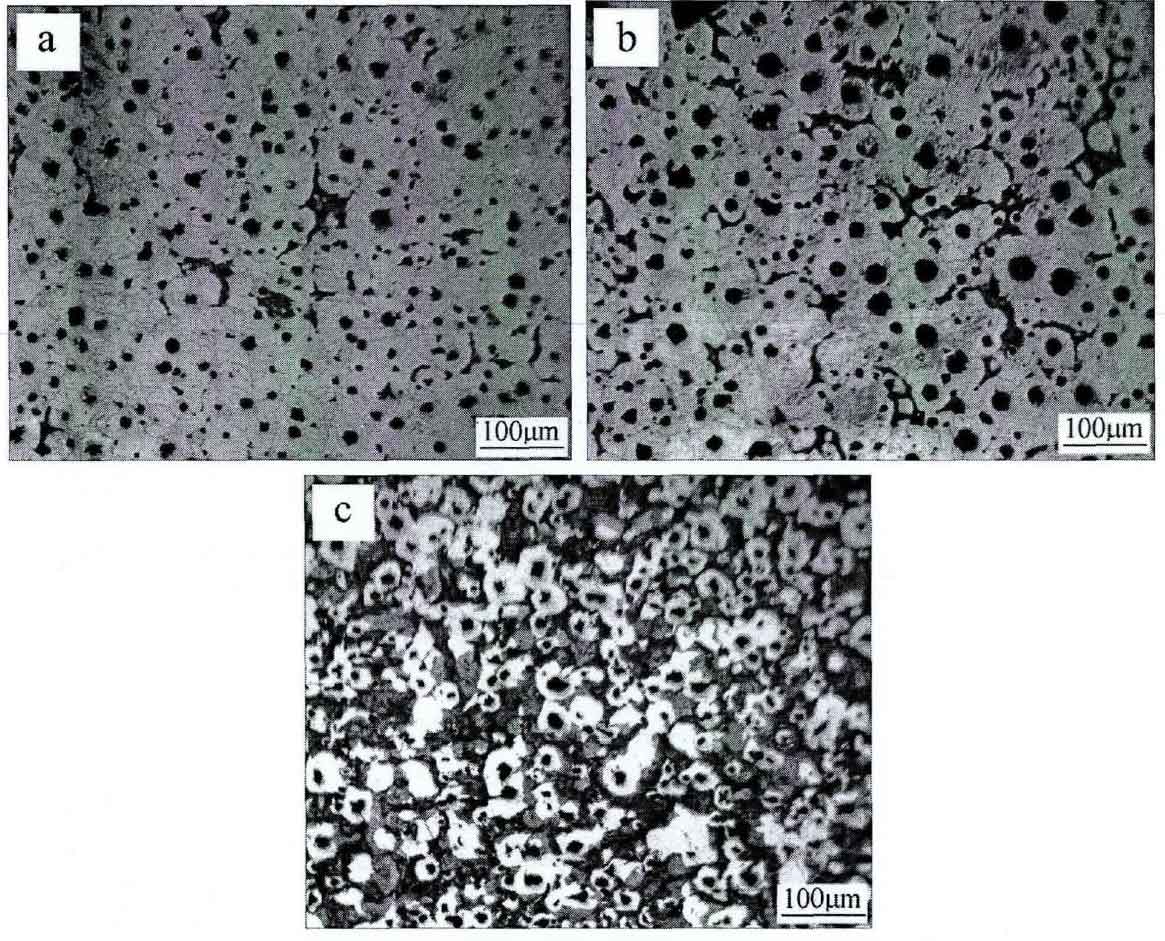

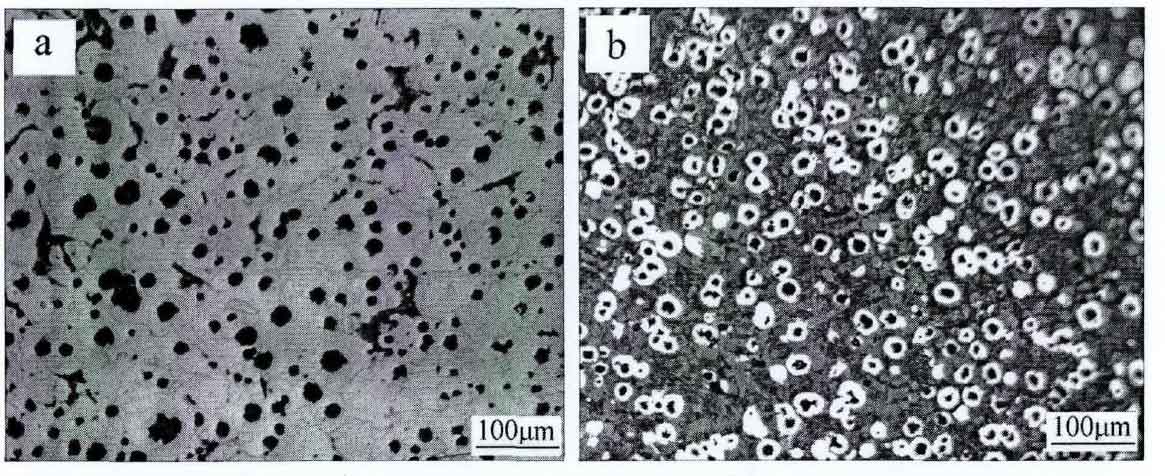

Figure 2 shows the effect of different copper content on the matrix. It can be seen from the figure that when copper is not added, the pearlite content of A1 is 15%, as shown in Figure 2A. When 0.2% copper is added, the pearlescent volume of A6 increases to 20%, as shown in Fig. 2B. When 0.3% copper is added, the pearlescent volume of B1 increases to 45%, as shown in Fig. 2C. It can be seen that copper promotes the formation of pearlite, and the pearlite content increases significantly with the increase of copper content.

Fig. 3 shows the effect on the matrix when copper and bismuth are added at the same time. It can be seen from the figure that when 0.2% copper and 0.006% bismuth are added at the same time, the pearlite content of A8 is 10%, between A6 and A7, as shown in Figure 3a. It can be seen that at this time, copper has little promoting effect on pearlite, while bismuth promotes the formation of ferrite. When 0.5% copper and 0.006% bismuth are added at the same time, the pearlite content of B4 is 75%, and the content increases significantly, as shown in Fig. 3B. At this time, the role of copper in promoting pearlite is obvious, the role of bismuth in promoting ferrite formation is no longer obvious, and the role of copper is significantly higher than that of chain, which is unfavorable to improving low temperature impact toughness.

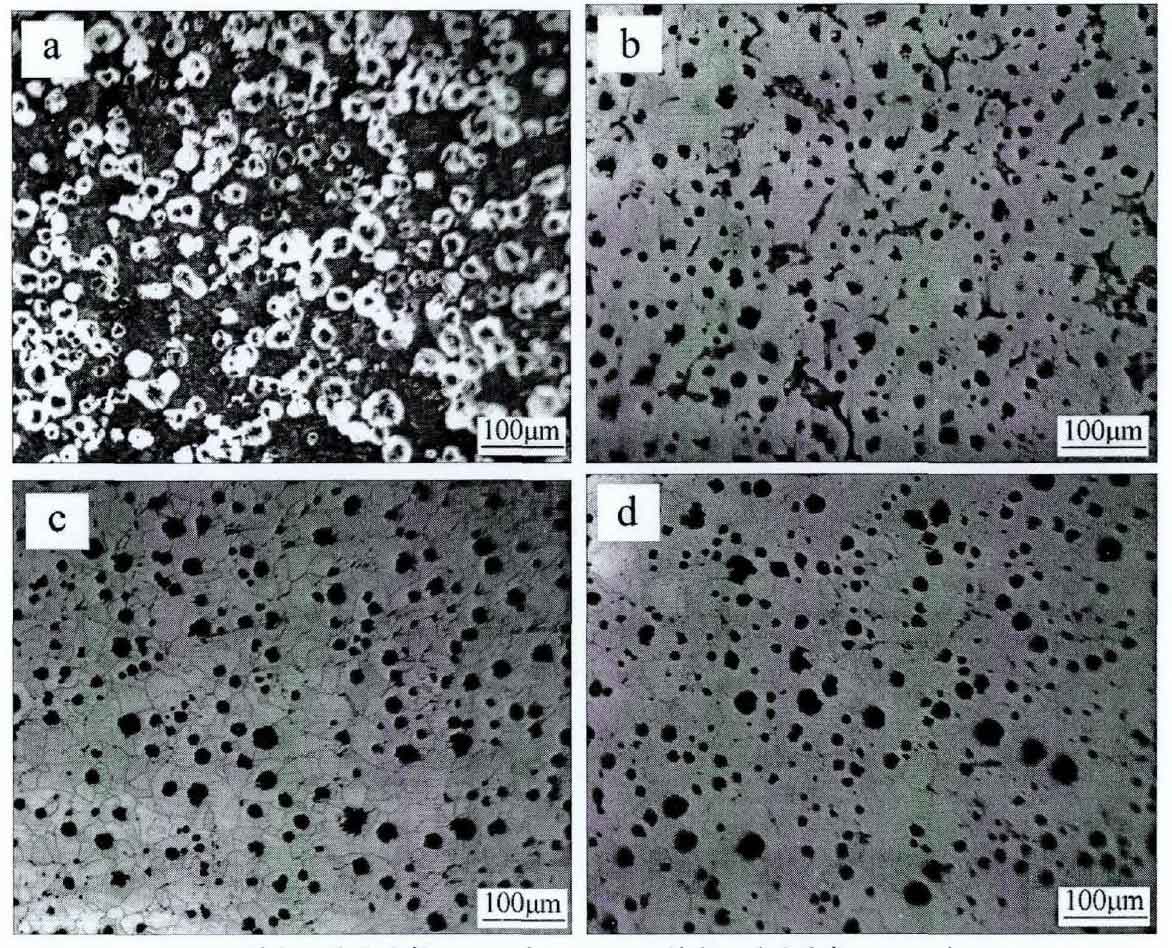

Figure 4 shows the effect of different production processes of nodular cast iron on the matrix structure.

It is found that although the inoculant dosage of A2 and A3 is the same, both of which are 1.7%, there are obvious differences in the obtained matrix structure: the pearlite content of A2 in as cast ductile iron is 55%, as shown in FIG. 4A, while the pearlite content of A3 in as cast ductile iron is 10%, which is significantly less than that of A2, as shown in Fig. 4B. This difference is mainly related to the adding method of inoculation. The inoculation amount at the bottom of A2 is 1.0%, the inoculation amount with flow is 0.6%, the inoculation amount at the bottom of A3 is reduced to 0.8%, and the inoculation amount with flow is increased to 0.8%. The inoculation effect can be significantly improved with the addition of 0.0% inoculation flow.

After heat treatment, the pearlite in the as cast structure of nodular cast iron disappears and the matrix is completely transformed into ferrite structure, as shown in figures 4C and 4D. Heat treatment has little effect on graphite ball, the uniformity of matrix is improved, and the grain boundary of ferrite is also increased obviously, which is beneficial to improve the mechanical properties of nodular cast iron.