1. Metallographic observation

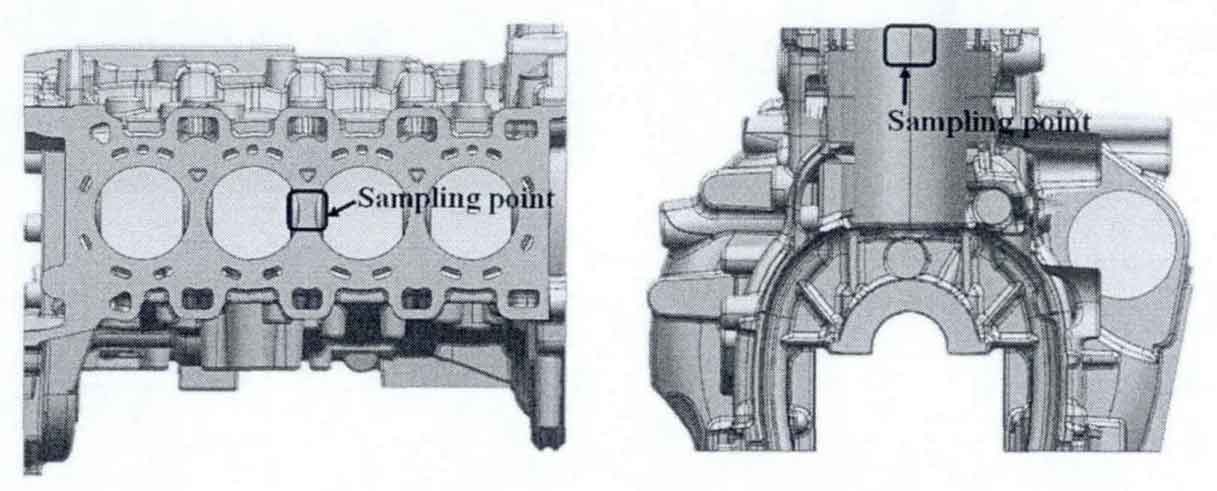

The metallographic sample is taken from the gray cast iron cylinder body, cut and sampled with a cutting machine, and the sampling position is shown in the figure. The removed samples are inlaid with epoxy resin, ground on 120, 280, 400 and 500 sandpaper respectively, and then polished on MP-1 metallographic sample polishing machine.

After the polished sample is cleaned by ultrasonic cleaning instrument, it is eroded with 4% nitric acid alcohol solution. The corroded samples can be observed under mr5000 metallographic microscope, which can clearly distinguish the distribution and size of various structures.

According to GB / t7216-2009, the graphite in gray cast iron is divided into 6 kinds according to its distribution shape and 8 grades in length. When observing the graphite distribution shape in gray cast iron, just polish the sample without erosion, enlarge it 100 times, and distinguish the type and size of graphite by comparing with the standard picture.

The quantity of pearlite is divided into eight grades, which is similar to the detection method of graphite. After the sample is eroded by 2% – 5% nitric acid alcohol solution, the content of pearlite is calculated by metallographic microscope (pearlite + ferrite = 100%).

2. SEM observation and energy spectrum analysis

The preparation method of SEM observation and energy spectrum analysis sample is the same as that of metallographic sample. Whether it is corroded can be selected according to the demand. Jsm-6490 scanning electron microscope is used to observe the cross-section and fracture morphology of the sample, and the energy dispersive spectrometer can detect the types and contents of elements in the micro area of the sample.

3. Phase analysis

The phase analysis adopts D / max-2500v Cu (KLA ray) lead X-ray diffractometer (XRD), the scanning angle is 10-90 °, the scanning speed is 4 ° / min, the test voltage is 40kV and the current is 40mA, The phase analysis of gray cast iron samples prepared by different processes and conditions was carried out.