In order to ensure the quality of wheel hub steel castings, the process scheme is optimized, and 14 65 mm pieces are evenly distributed in the outer circle of the oil leakage area × 50 mm × 30mm outer cold iron, and 30mm thick zirconium sand is placed in the inner circle; Place 5 pieces of 40mm at the root of 5 tie bars × 30 mm × 20 mm external cooling iron; On the premise that the size, position and quantity of risers remain unchanged, it is changed to 9 / 12K heating and thermal insulation riser sleeve produced by a company; Enlarge the riser allowance on the inner hole wall from the root of the tie bar to the middle riser, increase the feeding channel and enhance the feeding capacity of liquid steel. Adjusting the size of the enlarged riser subsidy can make the liquid steel form a bottom-up wedge-shaped feeding channel in the pouring process, and the oil leakage area and the root of the tie bar can be fully fed, which can completely solve the problem of blocking the feeding channel in the hub steel casting structure, and is also conducive to the liquid steel floating the floating sand in the cavity into the riser and eliminating the sand hole casting defects.

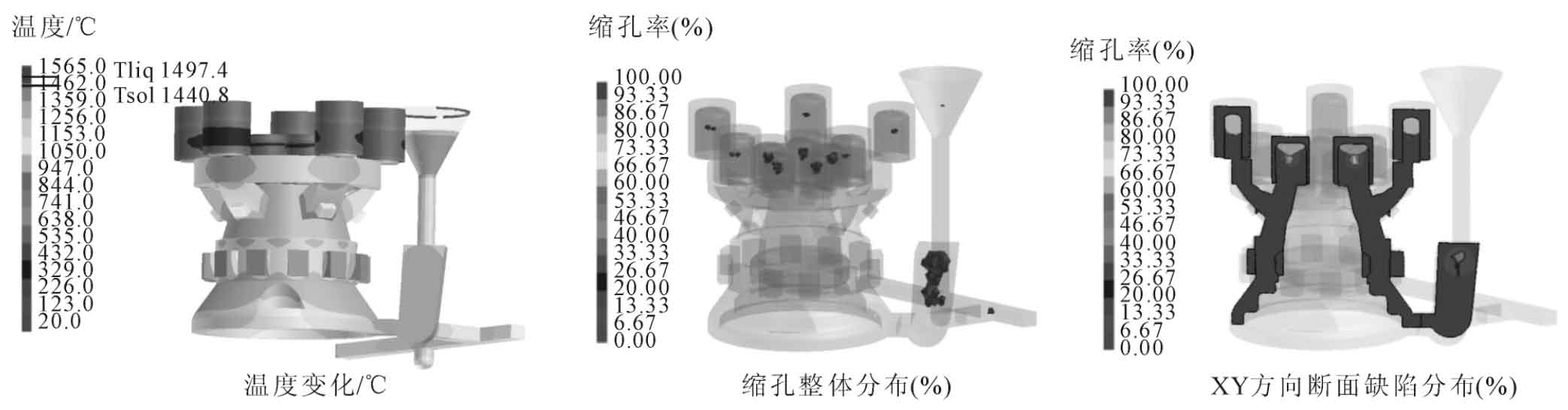

After three-dimensional modeling of the optimized process scheme, the numerical simulation calculation is carried out by using Pro cast simulation software, and the simulation results are shown in the figure.

From the analysis of simulation results, the optimized scheme has no shrinkage cavity and porosity casting defects in the original casting defects, and the shrinkage cavity and porosity casting defects are concentrated in the sprue and riser, which fully proves the feasibility of the optimized scheme.