Engine main bearing covers are critical automotive components operating under complex loads, demanding defect-free castings with stringent mechanical properties. Traditional trial-and-error methods prolong development cycles and increase costs. This study integrates numerical simulation with orthogonal testing to optimize the casting process for a 5-unit joint bearing cover made of QT500-7 ductile iron, achieving zero internal defects validated through industrial production.

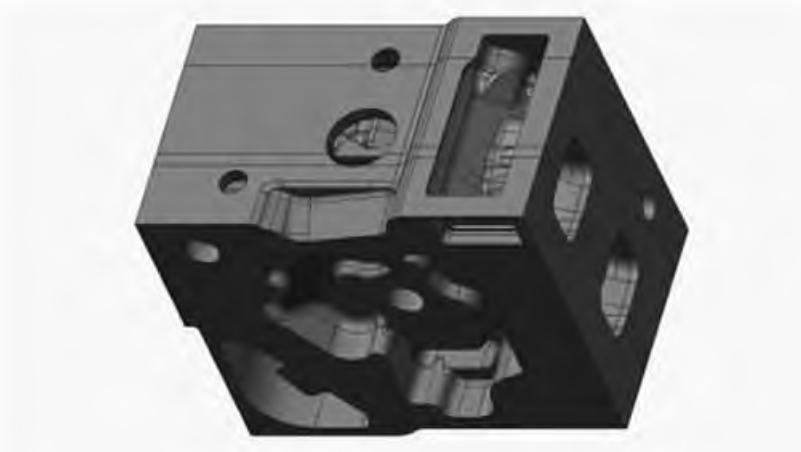

The casting geometry (148 mm × 114 mm × 68 mm, 5.4 kg mass) features 30 mm average wall thickness. Initial process design employed horizontal molding with a “one mold, four castings” layout. The gating system followed a choked-runner principle with $F_{\text{gating}} > F_{\text{runner}} > F_{\text{choke}}$ to minimize turbulence, where choke area $F_{\text{choke}}$ is calculated as:

$$F_{\text{choke}} = 720 \ \text{mm}^2$$

Riser design utilized modulus method calculations, with cylindrical risers (Ø70 mm × 140 mm) having a modulus of 1.31 cm. Chills were strategically positioned to enforce directional solidification, with chill offset distance $L$ defined as a key variable. The casting process design is illustrated below:

Three critical parameters were identified for optimization through a $L_9(3^4)$ orthogonal array:

| Level | A: Chill Offset (mm) | B: Pouring Temp (°C) | C: Pouring Speed (m/s) |

|---|---|---|---|

| 1 | 17 | 1370 | 1.5 |

| 2 | 27 | 1400 | 2.0 |

| 3 | 37 | 1430 | 2.5 |

Numerical simulations in AnyCasting employed 4,004,325 meshes with QT500-7 thermal properties: liquidus 1148°C, solidus 1080°C. Boundary conditions included:

| Interface | Heat Transfer Coefficient (W/m²·K) |

|---|---|

| Chill-Casting | 3000 |

| Chill-Sand | 1000 |

| Casting-Sand | $h(T) = \begin{cases} 300 & T \geq 1600^\circ\text{C} \\ 500 & 1200^\circ\text{C} \leq T < 1600^\circ\text{C} \\ 600 & 1100^\circ\text{C} \leq T < 1200^\circ\text{C} \\ 800 & T < 1100^\circ\text{C} \end{cases}$ |

Defect probability based on residual melt modulus served as the evaluation metric. Simulation results revealed:

| Trial | A (mm) | B (°C) | C (m/s) | Defect Probability (%) |

|---|---|---|---|---|

| 1 | 17 | 1370 | 1.5 | 0.09286 |

| 2 | 17 | 1400 | 2.0 | 0.08924 |

| 3 | 17 | 1430 | 2.5 | 0.08871 |

| 4 | 27 | 1370 | 2.0 | 0.08975 |

| 5 | 27 | 1400 | 2.5 | 0.08961 |

| 6 | 27 | 1430 | 1.5 | 0.08866 |

| 7 | 37 | 1370 | 2.5 | 0.10114 |

| 8 | 37 | 1400 | 1.5 | 0.09308 |

| 9 | 37 | 1430 | 2.0 | 0.09114 |

Range analysis quantified parameter influence magnitude:

$$R_j = \max(\bar{K}_{j1}, \bar{K}_{j2}, \bar{K}_{j3}) – \min(\bar{K}_{j1}, \bar{K}_{j2}, \bar{K}_{j3})$$

where $\bar{K}_{ji}$ is the mean defect probability for factor $j$ at level $i$. Results showed:

| Factor | $\bar{K}_1$ | $\bar{K}_2$ | $\bar{K}_3$ | Range $R$ |

|---|---|---|---|---|

| A: Chill Offset | 0.09027 | 0.08934 | 0.09512 | 0.00578 |

| B: Pouring Temp | 0.09458 | 0.09064 | 0.08950 | 0.00508 |

| C: Pouring Speed | 0.09153 | 0.09005 | 0.09315 | 0.00310 |

Factor significance followed A > B > C, indicating chill position dominantly impacts casting quality. Optimal levels were A2 (27 mm offset), B3 (1430°C), C2 (2.0 m/s), reducing defect probability to 0.08975% in simulation. Production trials with optimized parameters yielded X-ray validated defect-free castings, confirming the casting process robustness.

This methodology reduced development time by 68% versus conventional approaches while achieving ASTM E446 Level 2 internal quality. The casting process optimization framework demonstrates significant potential for complex safety-critical components.