1. Introduction

Investment casting is a widely used manufacturing process for producing complex-shaped components with high precision and quality. In this article, we focus on the investment casting process of a stainless steel bracket, which is an important component in various applications such as agricultural machinery. The aim is to optimize the process to reduce casting defects and improve the quality of the final product.

1.1 The Importance of Stainless Steel Bracket

The stainless steel bracket serves as a crucial connection between two important parts, transmitting rotational speed and torque. Its applications in different fields highlight the need for a reliable and efficient manufacturing process to ensure its performance and durability.

1.2 Challenges in Investment Casting of Stainless Steel Bracket

The complex external contour of the stainless steel bracket poses several challenges during the investment casting process. These include the formation of shrinkage defects during solidification, as well as issues such as air entrapment and inclusions during the filling process.

2. Casting Process Design

2.1 Bracket Structure and Material

The stainless steel bracket has an average wall thickness of 4 mm and a complex structure composed of a circular surface, a similar rectangular surface, and a U-shaped shell. The outer dimensions are 141 mm × 81.8 mm × 60.84 mm. The material used is 304L stainless steel with specific chemical compositions and phase transition temperatures.

| Chemical Composition (mass fraction, %) | Value |

|---|---|

| C | ≤0.03 |

| Si | ≤1.0 |

| Mn | ≤2.0 |

| Cr | 18.0 – 20.0 |

| Ni | 8.0 – 11.0 |

| S | ≤0.03 |

The liquidus and solidus temperatures are 1461.9°C and 1411.2°C respectively, and the density is 7.93 kg/m³.

2.2 Pouring System Design

- Pouring Channel Selection: Considering the complex shape of the bracket, a straight runner and an internal runner design are adopted for a shell mold with 2 pieces. This helps in improving the production efficiency and ensuring a smooth filling process.

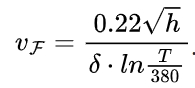

- Filling Speed Determination: The filling speed of the metal liquid is calculated using the Carlkin formula: . Based on the calculated value, a filling speed of 240 mm/s is selected.

2.3 Process Parameters

The process parameters are determined based on relevant experiments and the characteristics of the stainless steel 304L and the mold. These include the pouring temperature, mold shell preheating temperature, and filling speed.

| Process Parameter | Value |

|---|---|

| Pouring Temperature | 1500°C |

| Mold Shell Preheating Temperature | 1000°C |

| Filling Speed | 240 mm/s |

The mold shell consists of 6 layers of silica sol + refractory quartz sand with a thickness of about 8 mm. The casting is cooled in the negative Z direction under gravity using a top pouring method.

3. Simulation Analysis of the Original Process

3.1 3D Modeling and Mesh Generation of the Pouring System

The 3D model of the pouring system is established using Pro/E software and then imported into ProCAST software after being converted to.igs format. The mesh is generated with a total of 12,706 nodes and 104,753 elements, forming a 3D finite element model of the pouring system.

3.2 Setting of Simulation Parameters

In ProCAST, the following parameters are set:

| Parameter | Value |

|---|---|

| Casting Material | 304L |

| Pouring Temperature | 1500°C |

| Heat Transfer Coefficient (Casting – Mold Shell) | 1000 W/(m²·K) |

| Heat Transfer Coefficient (Casting – Air) | 1000 W/(m²·K) |

| Heat Transfer Coefficient (Mold Shell – Air) | 50 W/(m²·K) |

| Mold Shell Thickness | 18 mm |

| Cooling Method of Mold Shell | Air Cooling |

| Pouring Method | Top Pouring |

| Filling Speed | 240 mm/s |

| Gravity Acceleration | 9.8 m/s² |

3.3 Simulation Results and Analysis

- Filling Process: The metal liquid rises steadily in the cavity without impacting the cavity. The filling process is completed in 4 seconds, with specific time points for different stages of filling.

- Solidification Process: The casting solidifies from the outside to the inside and from the bottom to the top. The outer thin wall starts to solidify at 4 seconds, and the main body is almost completely solidified at 1042 seconds.

- Shrinkage Defect Analysis: The shrinkage rate of the original process scheme is predicted to be 21.450%, and some shrinkage defects are located in the main body of the casting, resulting in unqualified casting quality. This indicates that the numerical simulation is effective in predicting the defects.

4. Optimization of the Casting Process

4.1 Improvement of the Pouring System

- Analysis of Original Defects: The shrinkage defects in the original process are mainly located at the maximum hot spots, such as the rectangular connection, U-shaped shell, and the circle of the sidewall contact. The reason is that the internal runner solidifies first, blocking the feeding channel and resulting in insufficient feeding during volume shrinkage.

- Design of New Schemes: Two new process schemes are designed. Scheme a adds an internal runner below the straight runner, and scheme b adds an internal runner below the straight runner and an exhaust channel at the pouring cup position.

- Comparison of Schemes: After mesh generation and simulation analysis under the same process parameters and boundary conditions, the shrinkage rates of scheme a and scheme b are 8.4615% and 6.5089% respectively. Considering the fewer shrinkage defects in the main body of the casting in scheme b, it is selected for further optimization of process parameters.

4.2 Optimization of Casting Process Parameters

- Selection of Parameters for Optimization: Three process parameters related to the casting forming quality are considered: pouring temperature, mold shell preheating temperature, and filling speed. Different levels for each parameter are selected based on production experience and the characteristics of the stainless steel bracket.

| Level | Pouring Temperature (°C) | Filling Speed (mm/s) | Mold Shell Preheating Temperature (°C) |

|---|---|---|---|

| 1 | 1530 | 200 | 1000 |

| 2 | 1600 | 230 | 1050 |

| 3 | 1650 | 250 | 1100 |

- Orthogonal Experiment: An L9(3³) orthogonal experiment is conducted with the shrinkage rate as the main judgment index. The numerical simulation results of 9 groups of schemes are obtained, and the filling time and shrinkage rate of each scheme are recorded.

| Trial Number | Pouring Temperature | Filling Speed | Mold Shell Preheating Temperature | Filling Time (s) | Shrinkage Rate (%) |

|---|---|---|---|---|---|

| L1 | 1530 | 200 | 1000 | 6.780 | 1.716 |

| L2 | 1530 | 230 | 1050 | 5.459 | 2.752 |

| L3 | 1530 | 250 | 1100 | 4.883 | 2.574 |

| L4 | 1600 | 200 | 1050 | 5.864 | 1.345 |

| L5 | 1600 | 230 | 1100 | 5.417 | 1.360 |

| L6 | 1600 | 250 | 1000 | 4.929 | 1.367 |

| L7 | 1650 | 200 | 1100 | 5.864 | 1.346 |

| L8 | 1650 | 230 | 1050 | 5.365 | 1.343 |

| L9 | 1650 | 250 | 1000 | 4.850 | 1.345 |

- Selection of Optimal Scheme: Based on the simulation results, the shrinkage rates of L4, L7, L8, and L9 are relatively small and close. Considering production experience and cost control, the optimal process parameter scheme is A3B2C2, with a pouring temperature of 1650°C, a filling speed of 230 mm/s, and a mold shell preheating temperature of 1050°C.

5. Verification of the Optimized Process

5.1 Numerical Simulation of the Optimized Scheme

The shrinkage and porosity distribution of the optimized scheme is analyzed through numerical simulation. The results show that the casting quality is improved with a significant reduction in shrinkage and porosity defects.

5.2 Actual Production Verification

In actual production, the casting is produced according to the optimized process parameters. The appearance of the casting is good, and the defects are significantly reduced. The yield of the stainless steel bracket has been greatly improved.

6. Conclusion

- The ProCAST software is effectively used to simulate the investment casting process of the stainless steel bracket. By improving the pouring system and optimizing the process parameters, the shrinkage rate of the casting is significantly reduced, although some internal defects in the casting body still exist.

- The orthogonal experiment method is used to obtain the optimal process parameter scheme for the stainless steel bracket casting. The optimized process parameters are verified through numerical simulation and actual production, which provides a reference for the actual production of stainless steel bracket castings.