Nodular cast iron has become a material of choice in various industries due to its superior mechanical properties, including high strength, excellent ductility, and enhanced fatigue resistance. The casting process plays a critical role in determining the quality of nodular cast iron components. Optimizing these processes ensures the production of high-quality components that meet stringent industry standards. This article explores the key factors and advanced techniques in optimizing casting processes to achieve high-quality nodular cast iron components.

Introduction

The production of high-quality nodular cast iron components involves a series of carefully controlled casting processes. These processes must be optimized to ensure the desired mechanical properties, minimize defects, and achieve consistent results. This article examines the essential factors in optimizing casting processes, including material selection, mold design, melting and pouring techniques, and post-casting treatments.

Key Factors in Optimizing Casting Processes

Material Selection

The choice of raw materials significantly impacts the quality of the final cast iron components. The selection process includes choosing the right grades of pig iron, scrap steel, and ferroalloys. Ensuring the purity and appropriate composition of these materials is crucial for achieving the desired properties in nodular cast iron.

Table 1: Common Alloying Elements in Nodular Cast Iron

| Element | Effect on Properties |

|---|---|

| Carbon | Increases hardness and tensile strength |

| Silicon | Enhances fluidity and promotes graphitization |

| Magnesium | Induces nodularity in graphite |

| Copper | Improves strength and wear resistance |

| Nickel | Enhances toughness and corrosion resistance |

Mold Design and Preparation

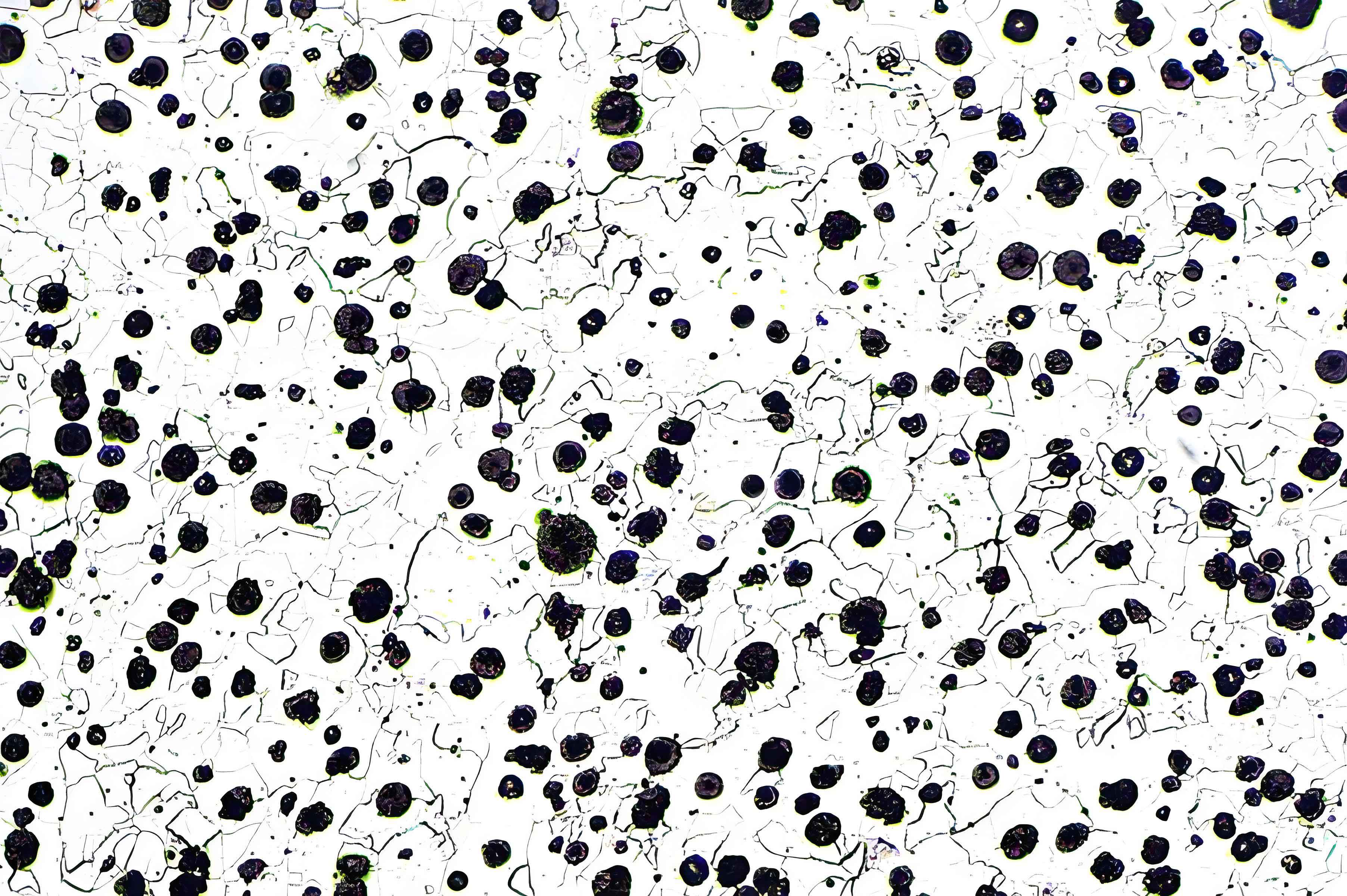

The design and preparation of molds are vital to achieving high-quality castings. Factors such as mold material, gating system design, and mold cooling rate directly influence the microstructure and mechanical properties of the cast iron.

- Mold Material: The choice of mold material affects the thermal conductivity and cooling rate, which in turn influences the microstructure of the casting.

- Gating System: An optimized gating system ensures smooth flow and proper filling of molten metal, minimizing defects such as porosity and inclusions.

- Cooling Rate: Controlled cooling prevents the formation of undesirable microstructures and ensures uniform hardness and strength.

Melting and Pouring Techniques

The melting and pouring stages are critical in maintaining the integrity and properties of nodular cast iron. Advanced techniques and equipment can enhance these processes:

- Induction Furnaces: Provide precise control over temperature and composition, reducing contamination and ensuring consistent quality.

- Inoculation: The addition of inoculants such as ferrosilicon helps control graphite nucleation, improving the nodularity and mechanical properties.

- Pouring Temperature: Maintaining an optimal pouring temperature prevents defects like cold shuts and ensures complete mold filling.

Table 2: Optimal Pouring Parameters for Nodular Cast Iron

| Parameter | Optimal Range |

|---|---|

| Pouring Temperature | 1350 – 1450°C |

| Inoculant Addition | 0.2 – 0.5% by weight |

| Pouring Time | 5 – 10 minutes depending on size |

Post-Casting Treatments

Post-casting treatments such as heat treatment and surface finishing play a crucial role in enhancing the properties of nodular cast iron components. These treatments help achieve the desired mechanical properties and surface characteristics.

- Heat Treatment: Processes like annealing, normalizing, and tempering improve the microstructure, increasing toughness and reducing residual stresses.

- Surface Finishing: Techniques such as shot blasting and machining improve surface quality, removing defects and preparing components for final use.

Case Study: Heat Treatment of Nodular Cast Iron

- Material: Nodular Cast Iron

- Heat Treatment Process: Austempering

- Benefits: Enhanced toughness, wear resistance, and fatigue strength

- Application: Heavy machinery gears and shafts

Advanced Casting Techniques

Recent advancements in casting technology have further optimized the production of high-quality nodular cast iron components. These include:

1. Computer-Aided Design (CAD) and Simulation

The use of CAD and simulation tools allows for precise mold design and process optimization. These tools help predict potential defects and optimize gating and cooling systems to achieve uniform microstructure and properties.

Benefits of CAD and Simulation:

- Reduced trial and error in mold design

- Improved accuracy in predicting casting defects

- Enhanced control over microstructure and mechanical properties

2. Vacuum Casting

Vacuum casting involves removing air from the mold cavity, reducing the risk of porosity and other defects. This technique is particularly useful for producing high-integrity components with complex geometries.

Benefits of Vacuum Casting:

- Minimizes gas entrapment and porosity

- Produces components with superior mechanical properties

- Suitable for complex and high-precision castings

3. 3D Printing of Molds

The use of 3D printing technology for mold production allows for greater design flexibility and precision. This technique can produce intricate mold designs that are difficult to achieve with traditional methods.

Benefits of 3D Printed Molds:

- Enables complex and customized mold designs

- Reduces lead time and costs in mold production

- Improves dimensional accuracy and surface finish

Table 3: Comparison of Traditional and Advanced Casting Techniques

| Technique | Traditional Casting | Advanced Casting |

|---|---|---|

| Mold Design | Manual, limited | CAD and 3D printing |

| Defect Prediction | Trial and error | Simulation tools |

| Porosity Control | Limited | Vacuum casting |

| Customization | Limited | High with 3D printing |

Conclusion

Optimizing casting processes is essential for producing high-quality nodular cast iron components that meet the demands of modern industrial applications. By focusing on key factors such as material selection, mold design, melting and pouring techniques, and post-casting treatments, manufacturers can achieve components with superior mechanical properties and minimal defects. Advanced techniques such as CAD, vacuum casting, and 3D printing further enhance the capabilities of the casting process, ensuring the production of high-integrity nodular cast iron components.