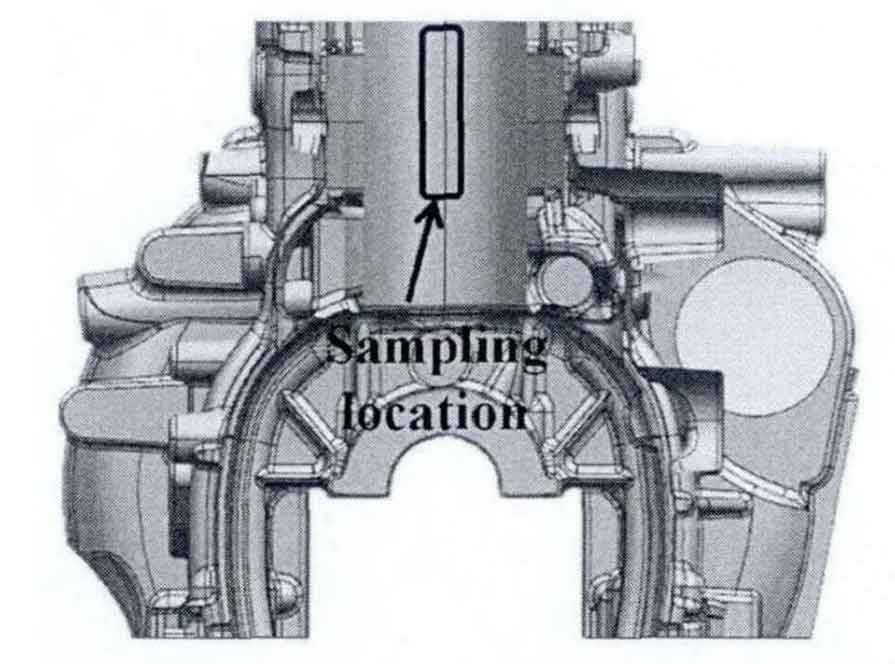

1. Hardness test

The sampling position of the hardness sample of the gray cast iron cylinder block is shown in Figure 1. The hardness test of the cylinder position needs to test the hardness for 3-4 times at equal intervals to test whether the hardness distribution of the cylinder is uniform.

The hardness of the cylinder barrel shall be tested by hb-3000b small load Brinell hardness tester. The size of the sample block shall be prepared according to the requirements of GB / t231.3-2012 Brinell hardness test of metal materials Part 3 – Calibration of standard hardness block. The sample block shall be ground and polished before the test, The surface shall be flat and smooth, free of oxide scale and external dirt, and the surface roughness Ra shall not be greater than 1.6am. The Brinell hardness test load is 30kgf and the pressure holding time is 10s, after multiple measurements of the indentation diameter, remove the average value, and finally query the results through the Brinell hardness test of metal materials: hardness value table in GB / t231.4-2009.

When analyzing the microstructure of gray cast iron, we also need to test its hardness for different structures. At this time, the sample hardness is measured by hmv-2 micro Vickers hardness tester. The sample treatment before measurement is the same as the above. The test load is 0.2kgf and the pressure holding time is 10s.

2. Tensile strength test

The tensile strength test of gray cast iron is carried out on cmt5105 microcomputer controlled electronic universal testing machine. The tensile rate is the preparation of tensile samples. The standard cylindrical samples in JB / t7945-1999 test method for mechanical properties of gray cast iron shall be single cast and processed, as shown in Figure 2, The roughness of the clamping part of the end face can be slightly higher than that to prevent slipping during stretching.