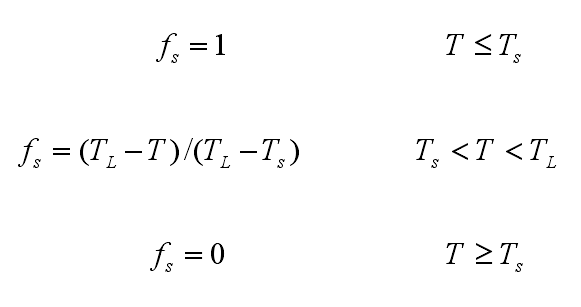

The defect of cold lap casting is due to the fact that the unit solid rate at the flow front reaches the critical solid rate during the filling process of high-temperature liquid metal, which leads to the stop of liquid metal flow and the defect of cold lap casting. When the critical flow rate of the casting is set to about 45.0, the critical flow rate can be set in the simulation process. Here, the solid phase ratio is related to the method of dealing with the latent heat of solidification. At present, equivalent specific heat capacity method, temperature rise method and enthalpy method can be used to deal with the precipitation of solidification crystallization latent heat. When the equivalent specific heat method is used to deal with the latent heat of solidification, the solid rate can be calculated by using the relationship between temperature and solid rate in the phase diagram. Assuming that it is a linear relationship, there are:

Where: lt – liquidus temperature, TS – solidus temperature.