By replacing the #3 riser with #5 riser, the height difference between riser and gray cast iron is increased from 4 mm to 19 mm, so as to improve the feeding capacity of riser. After trial production of 20 pieces, the shrinkage and looseness at the root of small end still exist, which can be measured by naked eyes. The analysis shows that increasing the height difference between riser and model has no effect on solving the shrinkage and looseness of brake drum.

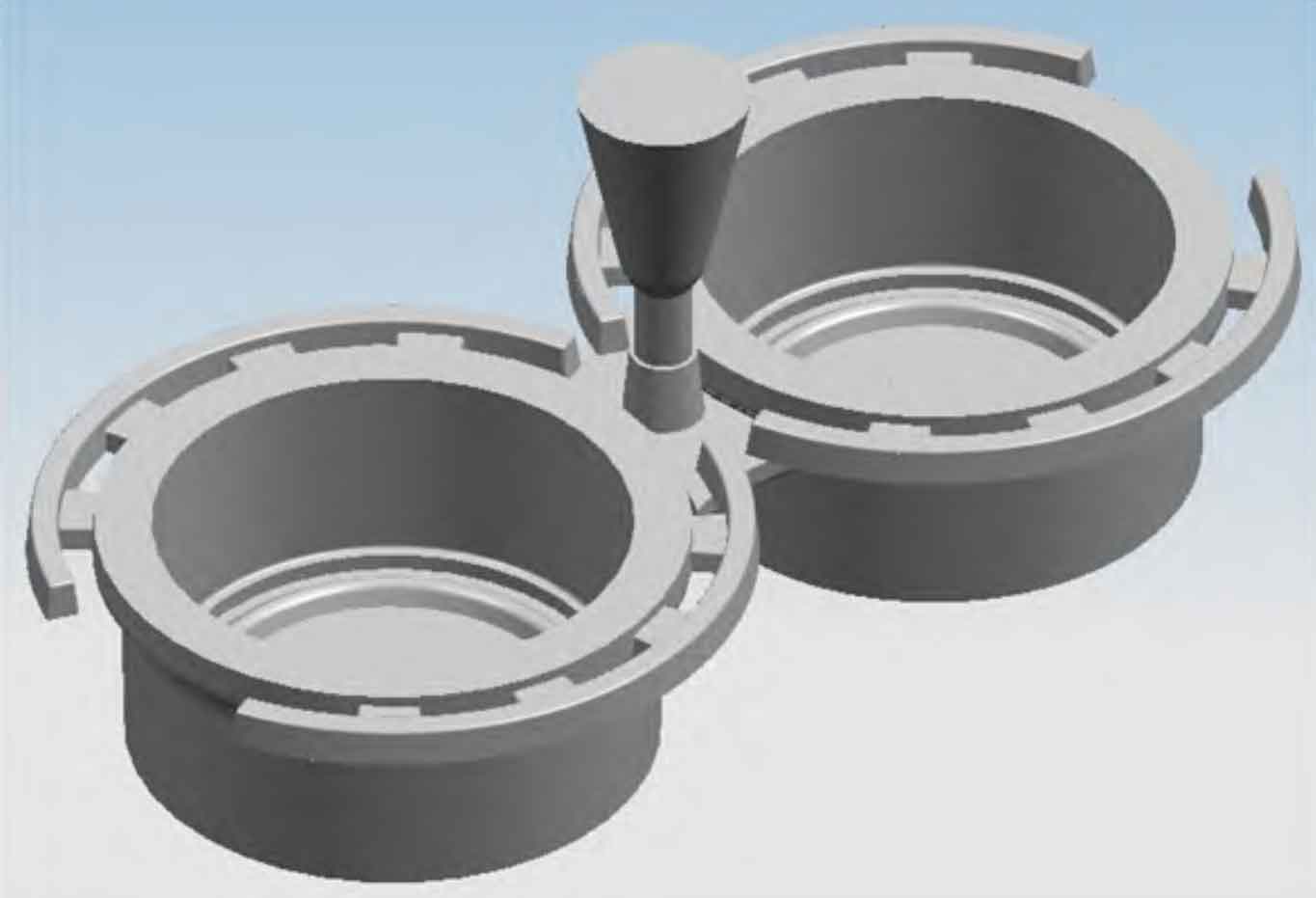

Because the structure of gray cast iron cannot be changed, the “large outlet flow theory” is used to solve the shrinkage problem. Redesign the casting process: remove the feeding riser, turn the main body of the model from the upper box to the lower box, and use the gravity feeding of molten iron; The annular sprue is adopted, the flow rate of the inner sprue is increased from 256.18 mm3 to 317.22 mm3, and the flow rate is reduced from 62.3kg/s to 43.83 kg / s. The improved casting process is shown in the figure. The gating system was changed from bottom injection to top injection, and the sprue cup was used to replace the riser for feeding, so that the process yield of gray cast iron was increased from 75.78% to 86.25%.

After trial production of 60 pieces, no shrinkage casting defects were found in gray cast iron, and then 1304 pieces were mass produced. The yield of gray cast iron increased from 89.72% to 92.58%.