1. Introduction

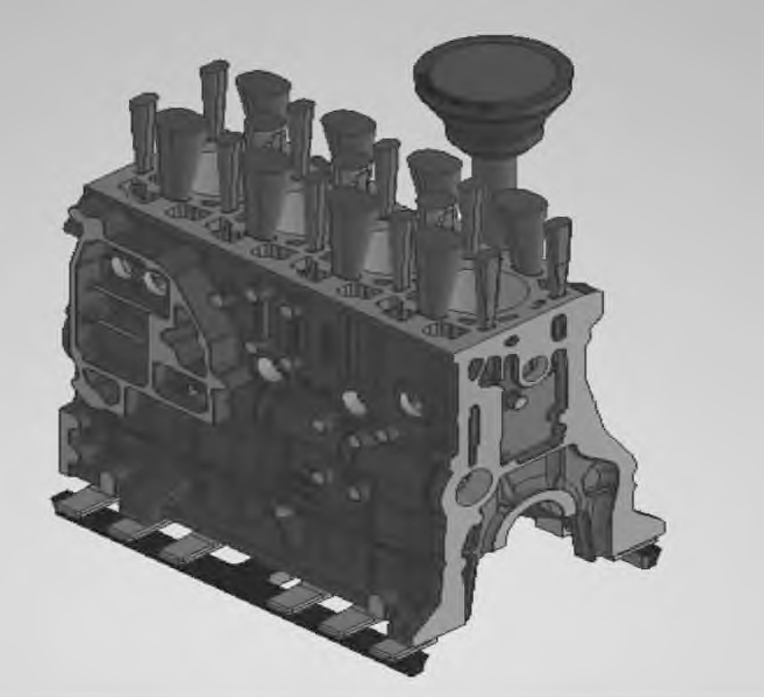

As a key component in automotive engines, the engine cylinder block directly impacts performance, durability, and efficiency. Over the years, advancements in casting technologies and materials have revolutionized the manufacturing of engine cylinder blocks, enabling higher precision, reduced defects, and improved mechanical properties. This article details our journey in designing and refining the casting process for engine cylinder blocks, leveraging simulation tools, material science, and innovative production techniques to achieve superior outcomes.

2. Market and Technical Challenges

The demand for engine cylinder blocks is driven by both automotive OEMs and the aftermarket. With rising vehicle production and stricter emission regulations, manufacturers face pressure to deliver lightweight yet robust components. Key challenges include:

- Minimizing defects such as shrinkage cavities, porosity, and cold shuts.

- Ensuring dimensional accuracy (CT7–CT9 standards).

- Optimizing production costs while maintaining high yield rates.

3. Material Specifications and Requirements

The engine cylinder block discussed here is made of HT250 gray iron, chosen for its excellent castability and thermal stability. Key specifications include:

Table 1: Chemical Composition of HT250

| Element | Content Range (%) |

|---|---|

| C | 3.2–3.35 |

| Si | 1.8–2.1 |

| Mn | 0.7–0.9 |

| S | ≤0.1 |

| P | ≤0.07 |

Mechanical Properties

- Tensile Strength: ≥250 MPa

- Hardness (HB): 180–210

4. Casting Process Design

4.1 Gating System and Pouring Technique

To address defects like cold shuts and misruns, we adopted a vertical gating system with bottom pouring. Key parameters include:

- Gating Ratio: ∑A直:∑A横:∑A内=1:2.3:8.7∑A直:∑A横:∑A内=1:2.3:8.7

- Sprue Dimensions: Φ40 mm

- Runner Dimensions: Φ40 mm × 30 mm

- Ingate Dimensions: Φ40 mm × 8 mm

4.2 Riser Design for Shrinkage Mitigation

Initial simulations revealed shrinkage cavities at the block’s top due to insufficient riser modulus. By increasing riser dimensions from 30 mm × 50 mm × 100 mm to 50 mm × 70 mm × 100 mm, we achieved better feeding and eliminated major defects.

5. Simulation-Driven Process Optimization

Using CAE software, we analyzed filling and solidification patterns to predict defect-prone zones.

5.1 Filling Analysis

- 30% fill – Early turbulence observed near ingates.

- 60% fill – Improved flow uniformity.

- 100% fill – Complete mold cavity occupation.

5.2 Solidification Analysis

- 30% solidification – Thermal gradients identified.

- 60% solidification – Risers began feeding.

- 100% solidification – Residual shrinkage localized to riser tips.

Post-optimization simulations confirmed defect reduction, validating our design changes.

6. Core Assembly and Coating Innovations

6.1 Core Manufacturing

The engine cylinder block mold comprises 14 cores, including:

- 4 main body cores

- 3 oil passage cores

- 2 cover plate cores

Cores were produced using cold-box (triethylamine) and hot-box (resin-coated sand) technologies to balance strength and gas emission.

6.2 Dip Coating Process

Post-assembly dip coating enhanced dimensional accuracy by 1–2 grades (CT9 achieved). Challenges included:

- Ensuring uniform coating thickness across complex geometries.

- Preventing drips or voids in internal passages.

7. Production Validation and Results

After implementing optimized processes, we produced 810 engine cylinder blocks with remarkable outcomes:

Table 2: Yield Rate Comparison

| Process Stage | Total Units | Defective Units | Yield Rate (%) |

|---|---|---|---|

| Pre-Optimization | 200 | 184 | 8 |

| Post-Optimization | 810 | 10 | 98.8 |

Defect Distribution

- Shrinkage: Reduced from 4 to 0 units.

- Porosity: Eliminated entirely.

- Dimensional Errors: Limited to 0.5% of total.

8. Key Improvements and Innovations

- Riser Modulus Adjustment: Solved shrinkage issues.

- Vertical Gating System: Minimized turbulence-related defects.

- Hybrid Core Technology: Balanced strength and gas venting.

- Dip Coating: Achieved CT9 precision.

9. Economic Impact

- Cost Reduction: 15% lower scrap rates.

- Cycle Time: 20% shorter due to reduced rework.

- Market Competitiveness: Enhanced via high-precision engine cylinder blocks.

10. Future Directions

- Explore additive manufacturing for complex cores.

- Integrate AI for real-time process monitoring.

- Develop lightweight alloys for next-gen engine cylinder blocks.

11. Conclusion

Through systematic process design, simulation, and iterative improvements, we achieved a 98.8% yield rate for engine cylinder block castings. Our approach underscores the importance of integrating CAE tools, material science, and innovative manufacturing techniques to meet evolving industry demands.