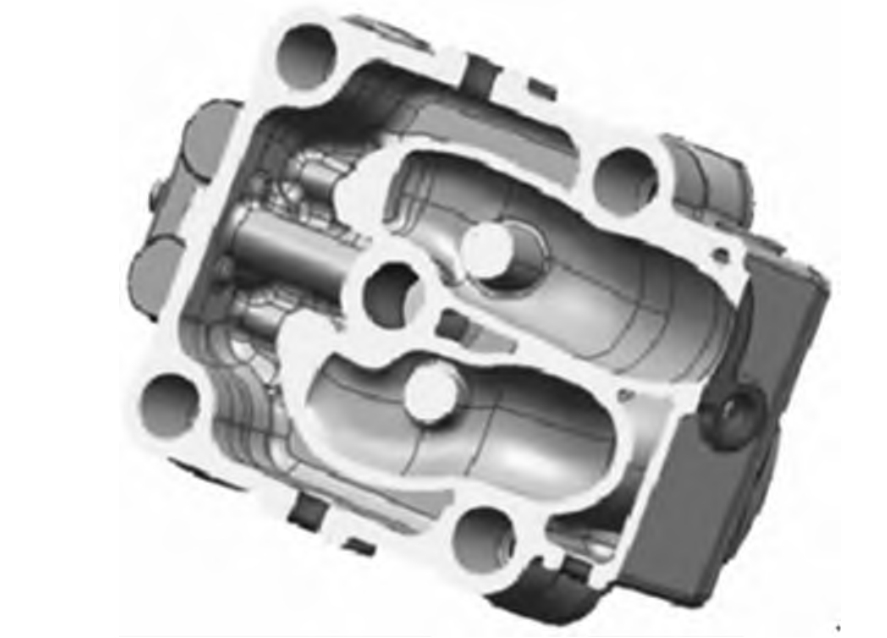

As a senior engineer specializing in casting production and management, I address critical challenges in manufacturing box-type machine tool beds. These components serve as the core skeleton of large-scale machine tools, directly influencing precision, performance, and service life through their load-bearing capacity. The thin-walled oil tank sections of these box beds frequently exhibit defects like chaplet fusion failure and gas entrapment, causing oil leakage during testing and potential scrap loss. This article details our comprehensive casting process optimization for a specific bed casting (HT300 grade, 2989 kg weight, 3100 mm × 1265 mm × 785 mm dimensions).

Structural Characteristics and Quality Specifications

The bed features variable wall thicknesses (15–90 mm), with critical quality requirements:

- Machined surfaces must be free of sand inclusions, gas holes, slag inclusions, and cold shuts

- Zero defects permitted in oil cavity regions

- Guide rail hardness >183 HBW without micro-porosity or structural looseness

- Visual surfaces must avoid sand holes, burn-on, or swelling defects

Initial Casting Process and Defect Analysis

Original Process Parameters

The initial casting process positioned guide rails downward with oil tank surfaces facing upward. Key parameters included:

| Material | Pig Iron | Machine Scrap | Steel Scrap | Carburizer | Ferrosilicon | Ferromanganese |

|---|---|---|---|---|---|---|

| Ratio | 5% | 35% | 60% | 2.0% | 0.7% | 0.4% |

| C | Si | Mn | P | S | Ti | Pb |

|---|---|---|---|---|---|---|

| 3.12±0.03 | 1.40±0.03 | 0.65±0.03 | ≤0.04 | 0.08–0.12 | ≤0.030 | ≤0.0015 |

Gating system design followed an open bottom-gate configuration with area ratios:

$$ \Sigma A_{\text{sprue}} : \Sigma A_{\text{runner}} : \Sigma A_{\text{ingate}} = 1 : 1.56 : 1.53 $$

Featuring a ø90 mm sprue, (105×84)×105 mm runner, and ingates (ø35 mm×4 + ø50 mm×3). Ten spherical risers (S100×8 + S80×2) were used without chills.

Persistent Quality Issues

Initial production of 13 castings revealed critical defects:

- 30.8% hardness failure (164–176 HBW) due to pearlite content below 90%

- Persistent slag inclusion on cope surfaces requiring extensive welding

- 53.8% scrap rate from gas explosions during pouring

- Chaplet fusion defects in critical oil tank sections

Root Cause Analysis

- Hardness Deficiency: Low pouring temperatures (1370–1390°C) and slow filling in open systems caused micro-shrinkage and pearlite reduction. The carbon equivalent (CE) further promoted ferrite formation:

- Slag Inclusions: Minimal cope surface venting and chaplet-induced sand erosion during core assembly

- Gas Explosions: Inadequate fixation of #10/#11 sand cores caused instability during metal entry

- Chaplet Fusion Failure: Localized cold zones from non-uniform filling

$$ \text{CE} = \text{C} + \frac{\text{Si} + \text{P}}{3} = 3.12 + \frac{1.40}{3} = 3.59 $$

Casting Process Optimization Strategy

Melting Process Upgrades

Composition adjustments focused on enhancing pearlite formation while reducing CE:

| Element | Original | Optimized | Metallurgical Impact |

|---|---|---|---|

| C | 3.12±0.03 | 3.07±0.03 | ↓ Graphitization, ↑ Pearlite |

| Si | 1.75±0.03 | 1.71±0.03 | ↓ Ferrite Stabilization |

| Mn | 0.65±0.03 | 0.95±0.03 | ↑ Pearlite Promotion |

Additional measures:

- Increased steel scrap ratio to enhance hardenability

- Pouring temperature raised to 1380–1400°C

- Two-stage inoculation with 0.6% FeSi (3–10 mm)

Casting Process Innovations

The revolutionary upgrade eliminated chaplets through 3D printed sand cores with integrated “benchmark core” alignment:

- Core Fixation: #8/#11 cores incorporated threaded rods for direct coupling with adjacent cores

- Assembly Gaps: Increased from 1.0 mm to 1.5 mm to prevent sand erosion

- Venting Enhancement: Cope overflow risers increased from 10 to 16 (+5850 mm² vent area)

- Gating Modification: Retained bottom-gating but optimized runner distribution for uniform filling

Validation of Optimized Process

Implementation in 40 castings demonstrated:

| Parameter | Original | Optimized |

|---|---|---|

| Hardness (HBW) | 164–185 | 183–192 |

| Pearlite Content | 80–90% | ≥95% |

| Tensile Strength (MPa) | 280–300 | 315–335 |

| Gas Explosions | 53.8% scrap | 0% occurrence |

| Chaplet Defects | Present in 100% | Eliminated |

This casting process redesign reduced scrap rates to <1.5% while enabling 72-hour mold stripping cycles.

Concluding Framework for Box Bed Casting

Validated improvements for thin-walled box structures:

- Casting Process Rule: Position oil tanks upward with guide rails downward

- Metallurgical Principle: Control CE < 3.5 through composition management

- Thermal Protocol: Maintain pouring temperatures ≥1380°C with minimum 72-hour solidification

- Core Methodology: Implement 3D printed benchmark cores for chaplet-free assembly

$$ \text{CE}_{\text{max}} = \text{C} + \frac{\text{Si}}{3} ≤ 3.50 $$

This integrated approach demonstrates how systematic casting process innovation resolves complex defect mechanisms in heavy-section castings.