The relentless pursuit of automotive lightweighting, driven by global environmental mandates and strategic initiatives like “Made in China 2025,” has cemented the role of light alloys such as aluminum in critical automotive components. Among these, steering valve housings are pivotal for vehicle control systems. Traditionally produced via gravity casting, these shell castings have seen research into high-pressure die casting alternatives. However, issues with porosity, surface defects, and low yield persist. Low-pressure die casting (LPDC) emerges as a superior process for such intricate, quality-critical shell castings. It operates at lower pressures, often eliminates the need for extensive risers, provides excellent feeding characteristics, and yields dense, sound castings with minimal environmental impact. The advent of sophisticated casting simulation software (CAE) has revolutionized process development, allowing for virtual prototyping. Yet, the effectiveness of simulation hinges on intelligent initial design and systematic parameter optimization. This work details a comprehensive methodology for the gating system design and process parameter optimization for an A356 aluminum steering valve housing produced via LPDC, with the primary objective of minimizing shrinkage porosity defects.

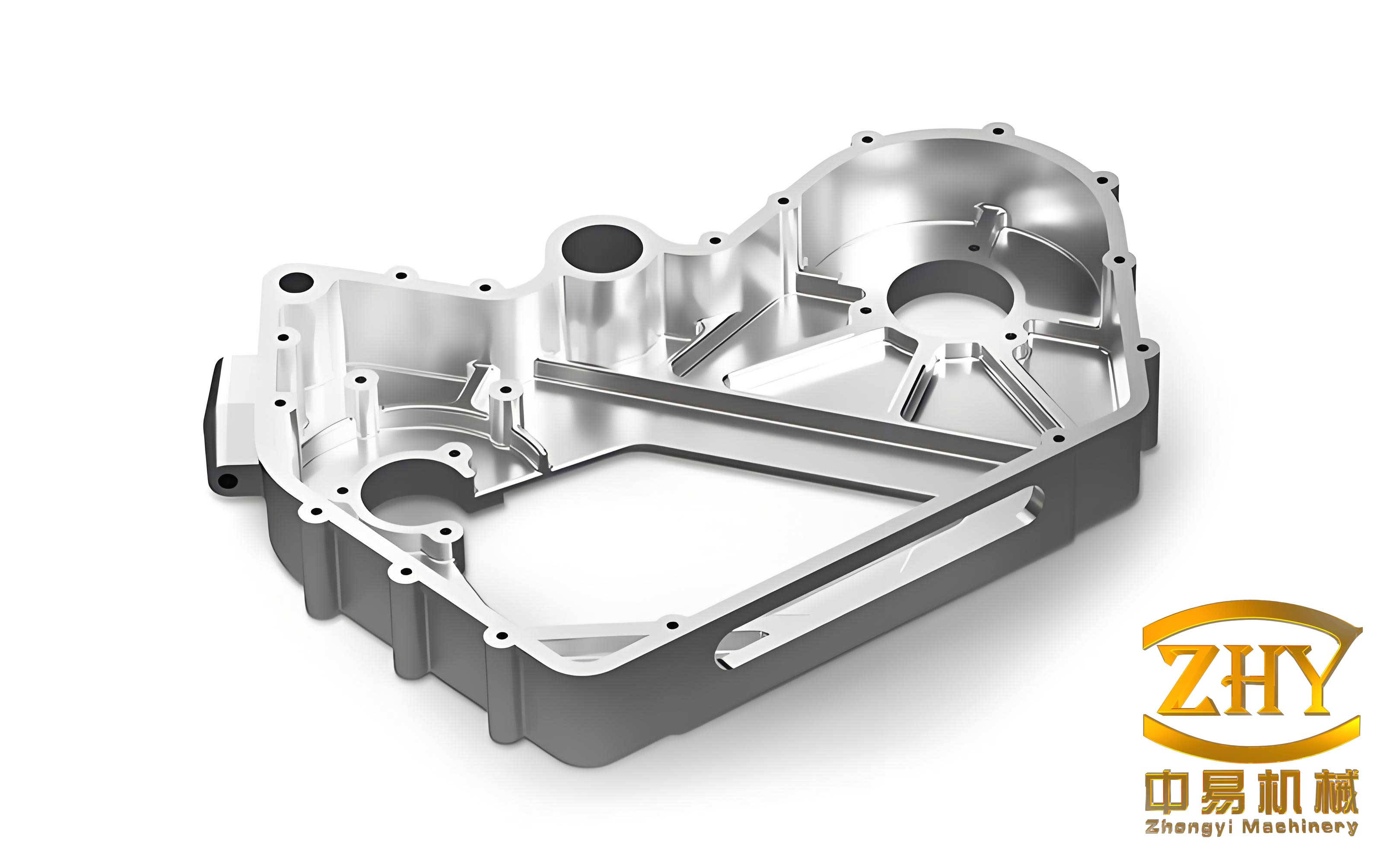

The component in question is a passenger car steering valve housing. Its 3D model, inclusive of necessary sand cores, reveals a complex geometry with varying wall thicknesses ranging from 5mm to 9mm and overall envelope dimensions of approximately 80mm x 85mm x 67mm. The successful casting of such shell castings demands careful consideration of fluid flow, heat transfer, and solidification dynamics. The material system is defined as follows: the casting alloy is A356 aluminum, the die material is H13 hot-work tool steel, and the cores are made of silica sand. The chemical composition of A356 is critical for its solidification behavior and final properties.

| Si | Mg | Fe | Mn | Cu | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|

| 7.0 | 0.4 | 0.5 | 0.3 | 0.03 | 0.1 | 0.15 | Bal. |

The interfacial heat transfer coefficients (HTC) govern the rate of heat extraction from the casting and are vital for accurate simulation. These values are assigned based on material pairings.

| Interface | Heat Transfer Coefficient |

|---|---|

| Casting – Sand Core | 500 |

| Casting – Die Steel (H13) | 400 – 620 |

| Die – Die | 3500 |

| Die – Sand Core | 500 |

The initial and most crucial step in process design is the gating system layout. For low-pressure die casting of shell castings, bottom-gating systems are predominantly used to ensure non-turbulent filling. Two distinct gating concepts were designed for the valve housing. Concept 1 oriented the part vertically with three circular-section ingates at the bottom. Concept 2 oriented the part horizontally with a single circular ingate at the bottom. Both systems were designed as pressurized, with a fixed ingate cross-sectional area of 220 mm² and runner/riser dimensions scaled accordingly (Ingate : Runner : Riser = 1 : 1.7 : 2.5).

| Concept | Part Orientation | Number of Ingates | Ingate Shape | Initial Process Parameters |

|---|---|---|---|---|

| 1 | Vertical | 3 | Circular | Fill Speed: 40 mm/s Pour Temp: 700°C Die Temp: 320°C Pressures: 2.6 / 7.5 / 20 kPa Intensification Time: 150s |

| 2 | Horizontal | 1 | Circular |

Numerical simulation of both concepts under identical initial parameters revealed significant differences. While both successfully filled the cavity, the defect analysis was decisive. Concept 1 showed a larger, isolated liquid region late in solidification, located far from the ingates and cut off from feeding by internal core features. This predicted a severe shrinkage cavity. Concept 2 also displayed a smaller isolated liquid zone, but it was closer to the ingate. The severity was predicted to be lower, and the defect was deemed potentially rectifiable through strategic design modifications and process tuning. Therefore, Concept 2 was selected as the baseline for optimization.

The optimization of the selected gating system proceeded in two stages: geometric modification and subsequent process parameter optimization. First, to improve feeding and reduce flow restriction, the single circular ingate was redesigned to an elliptical shape, increasing its cross-sectional area by approximately 20%. Second, to address the residual shrinkage in the topographically higher sections of the horizontal casting, a conformal cooling channel was designed in the upper die half. This channel, activated for a specific duration during solidification, promotes directional solidification towards the ingate.

Finally, the pressure-time profile was refined based on the modified geometry to ensure proper cavity filling and effective intensification pressure during solidification. A simulation of this optimized geometry with adjusted parameters showed a dramatic reduction in predicted shrinkage, confirming the effectiveness of the geometric and cooling strategy for these shell castings. With the geometry fixed, the focus shifted to fine-tuning the process parameters to eliminate the remaining minimal porosity and achieve robust production conditions.

To systematically identify the optimal process parameters, the Taguchi Design of Experiments (DOE) method was employed. This robust design approach is ideal for isolating the effect of multiple variables with minimal experimental runs. The objective was to minimize the shrinkage porosity volume, a “smaller-the-better” quality characteristic. Four key controllable factors were identified, each at three levels.

| Level | A: Pour Temp. (°C) | B: Top Die Temp. (°C) | C: Bottom Die Temp. (°C) | D: Fill Speed (mm/s) |

|---|---|---|---|---|

| 1 | 690 | 300 | 330 | 35 |

| 2 | 700 | 320 | 350 | 40 |

| 3 | 710 | 340 | 370 | 45 |

An L9 (3^4) orthogonal array was used, requiring only 9 numerical simulations. The output metric was the simulated shrinkage pore volume for each run. To analyze the results robustly against noise, the Signal-to-Noise (S/N) ratio was calculated for each trial. For the “smaller-the-better” objective, the S/N ratio is calculated as:

$$S/N = -10 \log_{10}\left(\frac{1}{n}\sum_{i=1}^{n} y_i^2\right)$$

where \(y_i\) is the observed shrinkage volume (a single value per simulation in this case, so n=1). A higher (less negative) S/N ratio indicates greater robustness and better performance (less shrinkage).

| Run No. | A: Pour Temp. | B: Top Die Temp. | C: Bottom Die Temp. | D: Fill Speed | Shrinkage Vol. (mm³) | S/N Ratio (dB) |

|---|---|---|---|---|---|---|

| 1 | 690 | 300 | 330 | 35 | 1.0 | 0.00 |

| 2 | 690 | 320 | 350 | 40 | 4.0 | -12.04 |

| 3 | 690 | 340 | 370 | 45 | 2.0 | -6.02 |

| 4 | 700 | 300 | 350 | 45 | 5.5 | -14.81 |

| 5 | 700 | 320 | 370 | 35 | 2.5 | -7.96 |

| 6 | 700 | 340 | 330 | 40 | 5.0 | -13.98 |

| 7 | 710 | 300 | 370 | 40 | 3.0 | -9.54 |

| 8 | 710 | 320 | 330 | 45 | 9.0 | -19.08 |

| 9 | 710 | 340 | 350 | 35 | 1.5 | -3.52 |

The analysis proceeds by calculating the average S/N ratio for each factor at each level. The main effect plot (derived from the response table below) visually shows the level of each factor that maximizes the S/N ratio. The optimal condition is the combination of levels that gives the highest overall S/N ratio. Furthermore, the range (R) of S/N values for each factor indicates its relative influence on the output; a larger range signifies a stronger effect.

| Level | A: Pour Temp. | B: Top Die Temp. | C: Bottom Die Temp. | D: Fill Speed |

|---|---|---|---|---|

| Level 1 Mean | -6.02 | -8.12 | -11.02 | -3.83 |

| Level 2 Mean | -12.25 | -13.03 | -10.12 | -11.85 |

| Level 3 Mean | -10.72 | -7.84 | -7.84 | -13.30 |

| Range (R) | 6.23 | 5.19 | 3.18 | 9.48 |

| Rank | 2 | 3 | 4 | 1 |

The analysis yields clear, actionable insights for producing high-integrity shell castings. Fill Speed (Factor D) has the most significant influence on shrinkage porosity, as indicated by its largest range (R=9.48). An excessively high fill speed in complex shell castings can lead to turbulent flow, jetting, and gas entrapment, which disrupts smooth thermal gradients and exacerbates shrinkage formation. The optimal level is 35 mm/s (Level 1). Pour Temperature (Factor A) is the second most influential parameter. A lower pouring temperature (690°C, Level 1) is optimal, as it reduces the total latent heat and superheat the die must absorb, promoting a faster and more controlled solidification front, which is beneficial for feeding in thin-walled shell castings. The die temperature parameters (B and C) also play a role. The optimal combination involves a higher bottom die temperature (370°C, C3) and a lower top die temperature (340°C, B3). This creates a strong vertical thermal gradient, encouraging directional solidification from the top (farther from the ingate) down towards the bottom and the ingate, which is crucial for effective feeding in low-pressure die casting of shell castings.

Therefore, the theoretically optimal parameter set derived from the Taguchi analysis is A1, B3, C3, D1: Pour Temperature = 690°C, Top Die Temperature = 340°C, Bottom Die Temperature = 370°C, Fill Speed = 35 mm/s. A final confirmation simulation using this parameter set in conjunction with the previously optimized gating geometry and cooling system predicted a virtual elimination of shrinkage porosity defects. The soundness of the casting was achieved by ensuring a controlled, laminar fill followed by a strong directional solidification pattern towards the ingate, facilitated by the strategic thermal management of the die.

This case study underscores a powerful, systematic methodology for developing robust low-pressure die casting processes for complex aluminum shell castings. The journey began with a critical assessment of part geometry and the selection of an appropriate bottom-gating strategy. Numerical simulation enabled the rapid evaluation and down-selection between competing gating concepts. The chosen concept was then refined through intelligent geometric modifications (ingate redesign) and the application of active thermal control (conformal cooling) to enforce favorable solidification dynamics. Finally, the Taguchi DOE method provided a scientifically rigorous framework to navigate the multi-variable process parameter space. By analyzing the S/N ratios, the dominant factors were identified and their optimal levels determined with minimal computational expense. The synergistic application of these tools—simulation, geometric optimization, and statistical design of experiments—leads to a first-time-right development approach. It significantly reduces the reliance on costly physical trial-and-error, shortens development time, and ensures the production of high-quality, reliable shell castings with minimized internal defects, meeting the stringent demands of the automotive industry for lightweight, high-performance components.

The physics underlying this optimization can be further elucidated through fundamental equations. The fluid flow during filling is governed by the incompressible Navier-Stokes equations, which for a Newtonian fluid in a gravitational field with pressure driving force (key in LPDC) can be simplified for analysis:

$$\rho \left( \frac{\partial \mathbf{u}}{\partial t} + \mathbf{u} \cdot \nabla \mathbf{u} \right) = -\nabla p + \mu \nabla^2 \mathbf{u} + \rho \mathbf{g}$$

where \(\rho\) is density, \(\mathbf{u}\) is velocity, \(p\) is pressure, \(\mu\) is dynamic viscosity, and \(\mathbf{g}\) is gravity. Controlling the fill speed (optimized to 35 mm/s) directly manages the inertial term (\(\mathbf{u} \cdot \nabla \mathbf{u}\)), preventing turbulence. The solidification and feeding efficiency are dictated by heat transfer and volume change. The thermal field is solved via the heat conduction equation with latent heat release:

$$\rho c_p \frac{\partial T}{\partial t} = \nabla \cdot (k \nabla T) + \dot{q}_{latent}$$

where \(c_p\) is specific heat, \(k\) is thermal conductivity, \(T\) is temperature, and \(\dot{q}_{latent}\) is the latent heat source term. The creation of a thermal gradient (\(\nabla T\)) by asymmetric die temperatures (top cooler, bottom hotter) is the driving force for directional solidification. Finally, the shrinkage porosity formation is intrinsically linked to the pressure drop in the mushy zone during the final stages of feeding, described simplistically by Darcy’s law for flow through a porous medium (the dendrite network):

$$\mathbf{u}_{feeding} = -\frac{K}{\mu} \nabla p_{local}$$

where \(K\) is the permeability of the mushy zone (which decreases rapidly as solid fraction increases), and \(\nabla p_{local}\) is the local pressure gradient. The optimization strategy ensures that a sufficient pressure gradient from the intensification phase is maintained all the way to the last regions to solidify, keeping \(p_{local}\) above the pore formation threshold. This integrated understanding of flow, thermal, and feeding mechanics provides the scientific foundation for the empirical optimizations, ensuring the reliable production of sound shell castings.