Abstract

Cast steel anchorages, as one of the core components of self-anchored suspension bridges, integrate multiple functions such as main cable anchoring, ballast, and limiting displacement. They are characterized by numerous angles on the outer contour surface and complex relative positions of anchoring holes. Taking the cast steel anchorage of a suspension bridge in China as an example, this paper proposes efficient processing technologies for the composite slope and anchoring space holes of cast steel anchorages, focusing on processing difficulties. These technologies can significantly improve production efficiency and reduce labor intensity during the mechanical processing of products, providing a reference for the processing of composite slopes and spatial holes.

Keywords: cast steel; self-anchored suspension bridge; anchorage processing; mechanical processing; efficiency improvement

1. Introduction

Self-anchored suspension bridges occupy an important position in modern bridge construction due to their unique structural design and excellent mechanical performance. The main cable anchoring system of domestic self-anchored suspension bridges typically adopts cast steel anchorages. The manufacturing quality of cast steel anchorages directly affects the overall performance and service life of bridges. However, the processing of cast steel anchorages faces many challenges, such as large structural dimensions, numerous angles on the outer contour surface, and complex relative positions of anchoring holes. Therefore, it is necessary to analyze the processing difficulties, select appropriate processing equipment, formulate reasonable processing techniques, and take corresponding technological measures to ensure product quality and improve processing efficiency.

2. Structural Characteristics and Processing Difficulties of Cast Steel Anchorage

2.1 Structural Characteristics

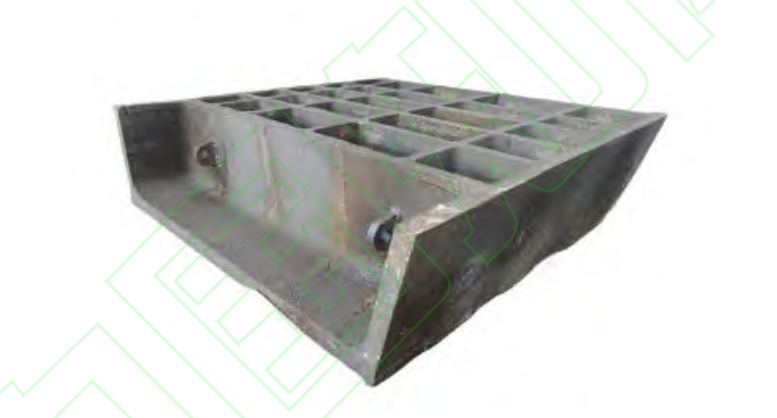

The cast steel anchorage discussed in this paper has large structural dimensions and significant mass. Its dimensions are 4425 mm × 3945 mm × 1200 mm, with a product mass of 54 t and a blank mass of 60 t. This presents higher requirements for the processing stroke and load-bearing capacity of manufacturing equipment.

The outer contour of the cast steel anchorage is complex, mainly manifested in non-90° angles between the top and bottom plates and the anchor surface. It has an irregular cuboid shape with two side webs perpendicular to the anchor surface and the bottom plate, but the bottom plate has a longitudinal slope α1, and the top plate has both a longitudinal slope α2 and a transverse slope α3.

The cast steel anchorage has a total of 61 anchoring holes, with each hole’s centerline having different angles. Theoretically, except for the central anchoring hole, the rest are not perpendicular to the anchor surface, and each hole’s centerline has a different angle with the anchor surface.

2.2 Processing Difficulties

- Large Size and Mass: The large size and mass of the cast steel anchorage pose challenges for processing equipment, requiring machines with sufficient stroke and load-bearing capacity.

- Complex Shape and High Precision Requirements: The complex shape and high precision requirements of the cast steel anchorage increase the difficulty of processing.

- Spatial Structure of Anchoring Holes: The spatial distribution and varying angles of the anchoring holes make it challenging to ensure accurate processing.

Table 1: Comparison of Cast Steel Anchorage Dimensions

| Dimensions (mm) | Mass (t) | Blank Mass (t) | |

|---|---|---|---|

| This Study | 4425 × 3945 × 1200 | 54 | 60 |

| Conventional Size | 2690 × 2930 × 804 | 14.2 | ~16 |

3. Processing Technology Solutions

3.1 Size and Mass Solution

To address the large size and mass of the cast steel anchorage, a numerical control (NC) floor-type milling-boring machine with a rotating worktable was selected. The machine’s X-axis and Y-axis strokes should be no less than 5000 mm, the Z-axis stroke should be more than 200 mm above the anchor surface thickness, and the rotating worktable’s load-bearing capacity should be above 60 t. Based on these requirements, the TK6926 NC floor-type milling-boring machine was chosen, equipped with a 140 t NC rotating worktable.

Table 2: TK6926 NC Floor-Type Milling-Boring Machine Specifications

| Specification | Value |

|---|---|

| Machine spindle diameter | ϕ260 mm |

| X-axis stroke | 18 m |

| Y-axis stroke | 6 m |

| Z-axis stroke | 1.6 m |

| Positioning accuracy (X, Y, Z axes) | 0.02 mm/1000 mm |

| Rotating worktable load-bearing capacity | 140 t |

| Worktable dimensions | 5000 mm × 5000 mm |

3.2 Outer Shape Processing Technique

The cast steel anchorage has a total of six outer processing surfaces. The anchor surface, grid surface, and both side web surfaces are mutually perpendicular or parallel planes, but the bottom and top plates are not perpendicular to the anchor surface.

To reduce setup times and ensure processing accuracy, the cast steel anchorage was placed on the rotating worktable with the anchor surface perpendicular to the machine spindle. With this setup, all outer surfaces could be processed in two setups using the rotating function of the worktable.

Table 3: Comparison of Outer Shape Processing Setup Times

| Method | Number of Setups | Setup Time per Time (h) | Total Setup Time (h) |

|---|---|---|---|

| Conventional Method (without Rotating Worktable) | 6 | 4 | 24 |

| Method Described in This Paper (with Rotating Worktable) | 2 | 4 | 8 |

3.3 Anchoring Hole Processing Technique

Each of the 61 anchoring holes in the cast steel anchorage has different angles for α4 and α5. To process these holes efficiently, the composite angles of the anchoring hole centerlines were decomposed into projection angles in the XZ and YZ planes. With the anchor surface perpendicular to the spindle, the holes were processed using X, Y, and Z three-axis linked oblique linear tool paths.

Table 4: Comparison of Anchoring Hole Processing Setup Times

| Method | Number of Setups/Adjustments | Setup/Adjustment Time per Time (h) | Total Setup/Adjustment Time (h) |

|---|---|---|---|

| Method 1 | 60 | 5 | 300 |

| Method 2 | 60 | 2 | 120 |

| Method Described in This Paper | No additional setup needed | – | – |

4. Conclusion

By analyzing the structural characteristics of cast steel anchorages and selecting the appropriate processing equipment, efficient processing techniques were developed to significantly improve production efficiency while ensuring product quality. This study provides a reference for the high-efficiency processing of large-volume and complex-structured anchorages and offers insights