Through 3D simulation and analysis of the casting process of the vacuum pump shell casting, a reasonable gating system was designed. The white mold of the vacuum pump shell was cut with the foam cutting program to ensure the smooth implementation of mold assembly. The molten iron was spheroidized with the wire feeding spheroidization process, and the quality of the casting met the technical requirements. Finally, it is pointed out that: (1) the production of thick ductile iron vacuum pump housing using the lost foam process is feasible. The white mold is cut into pieces by CNC, manually combined and bonded, and the casting size accuracy is high; (2) The iron liquid adopts a double wire feeding spheroidization process with a cover, ensuring the quality of the iron liquid feeding and meeting the material requirements of the casting; (3) The casting process adopts top injection pouring and riser shrinkage filling technology, achieving a smooth, orderly and sequential solidification of the filling process. The casting structure is dense, without shrinkage, looseness or leakage.

Casting process

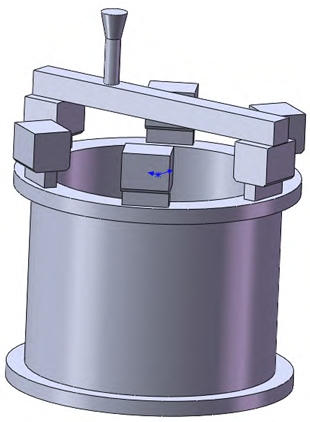

The outer dimensions of the vacuum pump housing casting are relatively large, with a maximum outer dimension of φ 864 mm × 637 mm. The wall thickness of the casting cylinder is 35mm, and the single weight of the casting is 425 kg. The schematic diagram of the outer structure is shown in Figure 1, and the material grade is QT600-3. The technical requirement is that the casting must not leak. The size of the sand box is 1200mm × 1000mm × 1300mm, with one piece per box. The casting box weighs 560 kg and is filled with 700kg spheroidized iron liquid. The wire feeding method is used for spheroidization treatment [1-4]. The pouring temperature of the iron liquid is set at 1430-1450 ℃, and the vacuum negative pressure is applied Control at -0.05~-0.06 MPa, and set the holding time for 1 hour after pouring the molten iron to prevent deformation of the casting. Adopting a top injection and semi open pouring system, the sprue ratio is ∑ F straight: ∑ F horizontal: ∑ F internal=1:1.4:1.2. The cross-sectional size of the straight sprue is 50mm, the cross-sectional size of the horizontal sprue is 75mm × 75mm, the cross-sectional size of the inner sprue is 40mm × 140mm, and the riser size is 120mm × 120mm × 14mm. The riser is evenly distributed on the top of the casting. In the casting process, due to the inconvenient arrangement of external cold iron in the lost foam process, using internal cold iron will cause poor fusion. Therefore, the riser shrinkage process is used to eliminate shrinkage or looseness in the casting. Six risers are placed at the top of the casting Risers, two of which are hot risers. The molten iron enters the mold cavity from the hot risers, first falling into the bottom of the mold cavity, and then the liquid level of the molten iron rises. When the molten iron reaches the top of the mold cavity, the leading edge of the molten iron enters the other four risers. After the molten iron is filled, the six risers together make up for the shrinkage of the casting.

To verify whether the top injection process is reasonable, whether the filling of molten iron can ensure smooth pouring, and whether the pouring system can effectively supplement the shrinkage position of the casting, MAGMA numerical simulation software was used to simulate the filling and solidification process of the pouring process. The top injection process was used for pouring, and molten iron entered the mold cavity from the pouring system and fell into the mold At the bottom of the cavity, it gradually rises from the bottom and the filling process is stable. The molten iron in the lower part gradually cools down as the molten iron is filled, and the hot molten iron entering the upper part compensates for the solidification of the molten iron in the lower part., During the solidification process of the casting, the riser finally solidifies, playing a good role in supplementing shrinkage, and no large isolated liquid phase zone is observed throughout the entire process. Localized small isolated liquid phase regions can be compensated for by slight shrinkage through graphitization expansion.

The size of the vacuum pump housing casting is relatively large, and it is not possible to make a complete white mold of the casting at once. Therefore, the white mold can only be made by splicing. First, the vacuum pump shell casting is decomposed into several pieces with CAD software, and then the full-automatic CNC cutting platform is used for cutting. Among them, the vacuum pump shell cylinder is decomposed into 12 pieces, and the flanges at both ends of the vacuum pump shell are decomposed into 8 pieces. The cylinder fillet size is R10mm, and fine foam strips are used. Manually splice the cut foam blocks. First, align the center of the circle on the glass plate, then align the cut foam blocks, and use fiber sticks to bond the foam fixed position; Then apply glue and wrap paper tape to the gaps in the white mold to eliminate them and prevent paint from entering the gaps during immersion coating. To prevent deformation of the white mold of the vacuum pump housing during coating, two wooden strips with a cross-sectional size of 15mm × 15mm are bonded to the upper and lower ends of the white mold for reinforcement. To prevent shrinkage or looseness in castings, a casting system is used in the process to supplement shrinkage. Finally, fiber rods are used to bond and reinforce the white mold riser to prevent damage to the white mold during production.

Due to the enlarged appearance of the vacuum pump housing after mold assembly, it is required to apply the coating to every position of the white mold during immersion coating. Firstly, the operator slowly rotates the white mold while immersing it in the coating pool, and then uses a small container to pour the coating onto the areas where it is not easy to immerse the white mold. After coating, place the yellow mold in a dedicated drying rack On the car, push it into the drying room for dehumidification and drying.

To reduce shrinkage or porosity defects in castings, the pouring temperature of the molten iron is set to 1430-1450 ℃. Clean cold iron blocks should be placed at the pouring site to prevent the pouring from being affected when the temperature of the molten iron is higher than 1450 ℃. During pouring, clean cold iron blocks should be immediately put into the pouring ladle for cooling. After pouring, the mold cavity should be filled with molten iron. During pouring, the vacuum negative pressure on site should be controlled at -0.05~-0.06MPa, and the holding time after pouring should be set to 1 hour.

Conclusion

(1) The production of thick ductile iron vacuum pump housing using the lost foam process is feasible. The white mold is cut and divided by CNC, manually assembled and bonded, and the casting size accuracy is high, suitable for small-scale production.

(2) The iron liquid adopts a double wire feeding spheroidization process with a cover, ensuring the quality of the iron liquid feeding and meeting the material requirements of the casting.

(3) The casting process adopts top injection pouring and riser shrinkage filling technology, achieving smooth, orderly and sequential solidification of the filling process. The castings are dense, without shrinkage or leakage, meeting customer requirements.