Melting process of nodular cast iron: add it in the order of scrap – pig iron – return charge, control the melting temperature to be less than 1 370 ℃, and add carburetor in two times according to different melting percentage of charge. Conduct pre-furnace analysis when the furnace charge is fused to 90%. Necessary adjustment shall be made according to the analysis results before the furnace, and the furnace shall be discharged after smelting to the furnace temperature.

Chemical composition requirements of ductile iron scrap: C mass fraction is 0.1%~0.3%; Si mass fraction ≤ 0.30%; Mn mass fraction ≤ 0.30%; P mass fraction ≤ 0.04%; S mass fraction ≤ 0.04%; Cr mass fraction ≤ 0.25%.

Chemical composition requirements of carburizing agent for nodular cast iron: fixed carbon mass fraction ≥ 98%; Mn mass fraction of ash ≤ 0.30%; Volatile matter mass fraction ≤ 0.20%; S mass fraction ≤ 0.03%.

Spheroidizing and inoculation treatment of nodular cast iron: first put the nodularizing agent accounting for 1.5% of the mass of molten iron into the pit at the bottom of the ladle, tamp it with an iron holder, then put the silicon-barium inoculant on the nodularizing agent, tamp it with an iron holder, and then cover and tamp it with baked ductile iron filings, add alloy, and cover it with perlite. After pouring molten iron for the first time during tapping, pour the remaining molten iron after the spheroidization reaction is over, and add the secondary silicon barium inoculant along with the flow.

| Number | Tensile strength/MPa | Elongation/% | Hardness (HBW 10/3 000) |

| #1 | 807 | 6 | 251 |

| #2 | 813 | 5.5 | 253 |

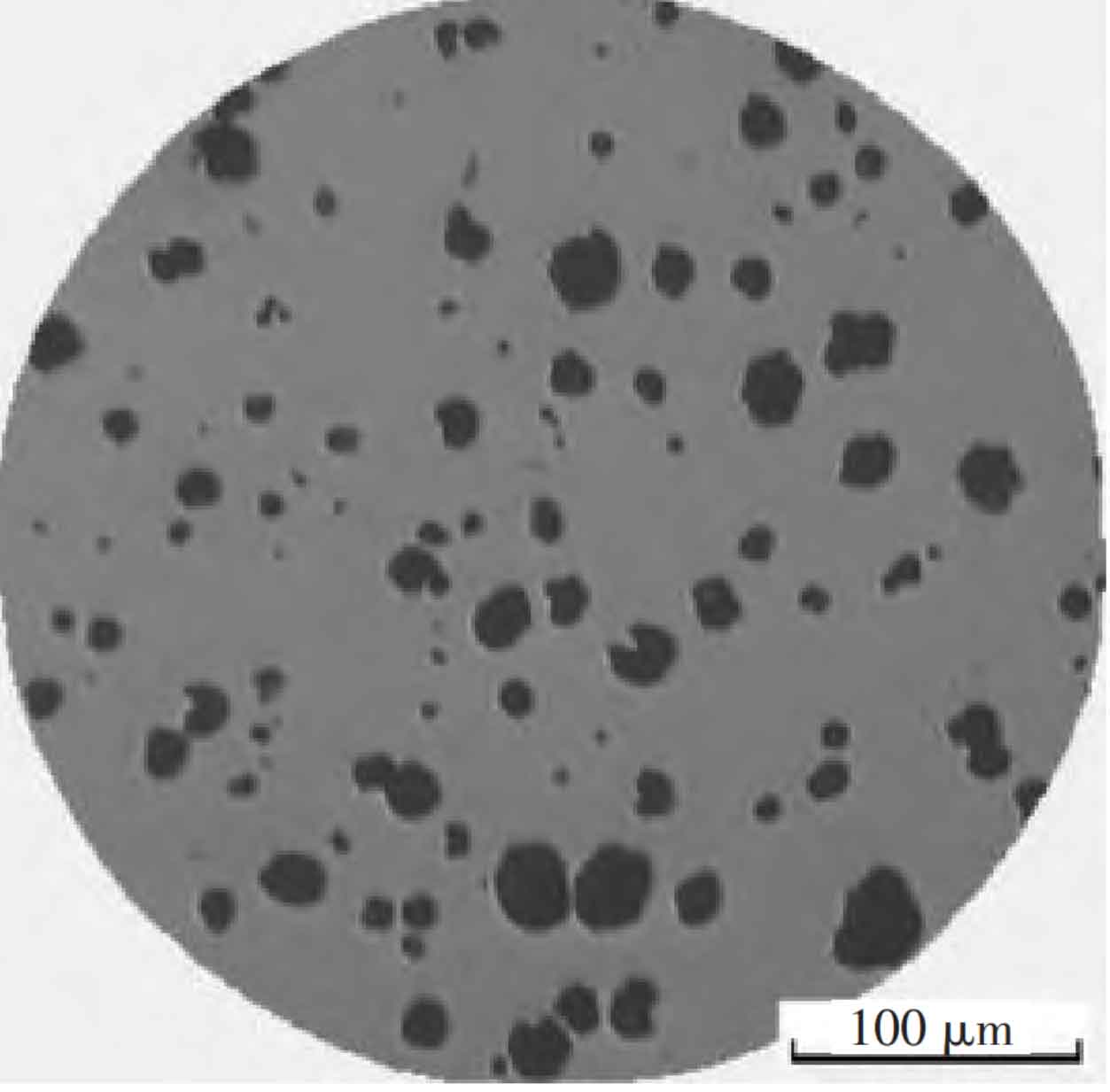

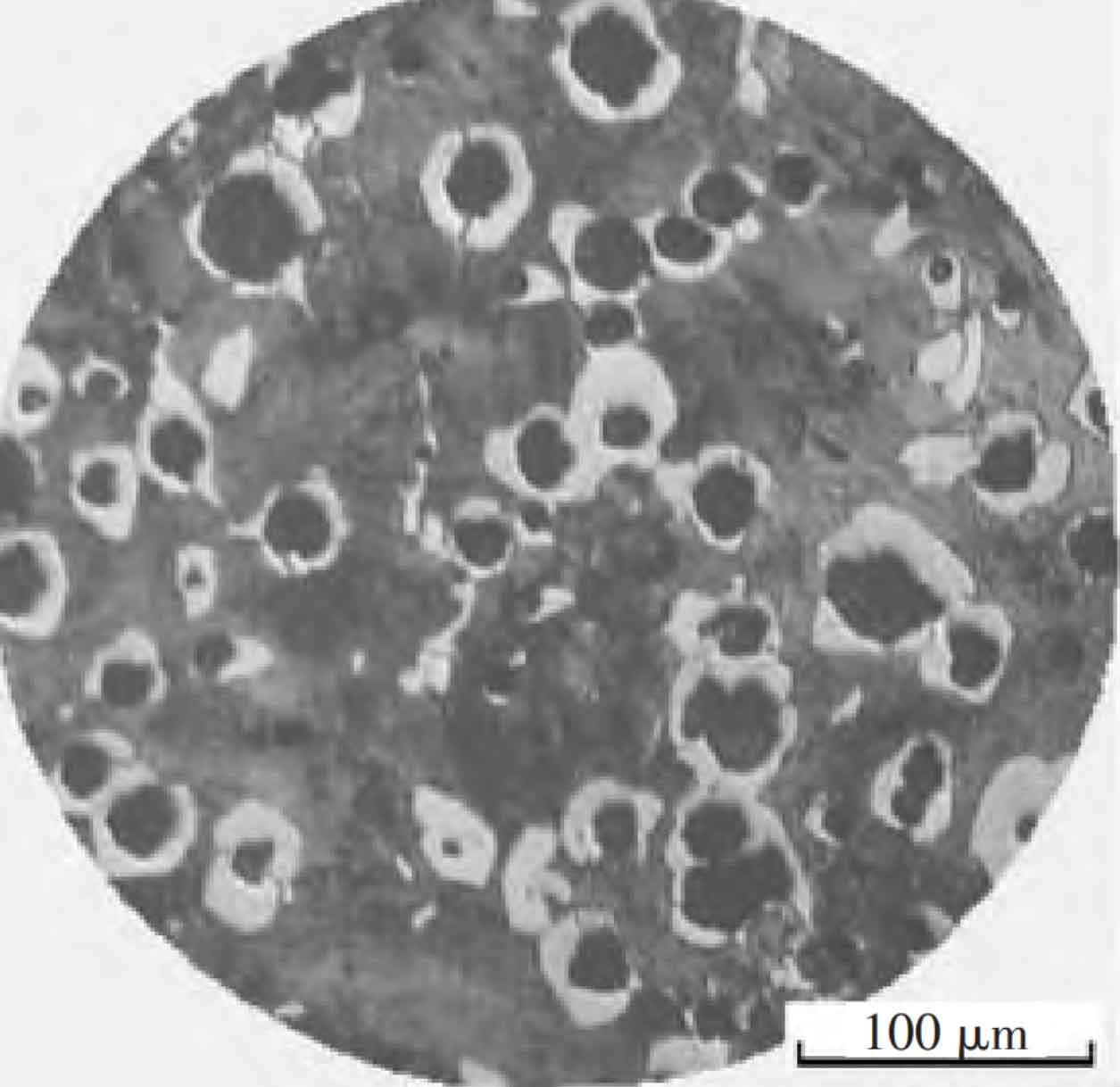

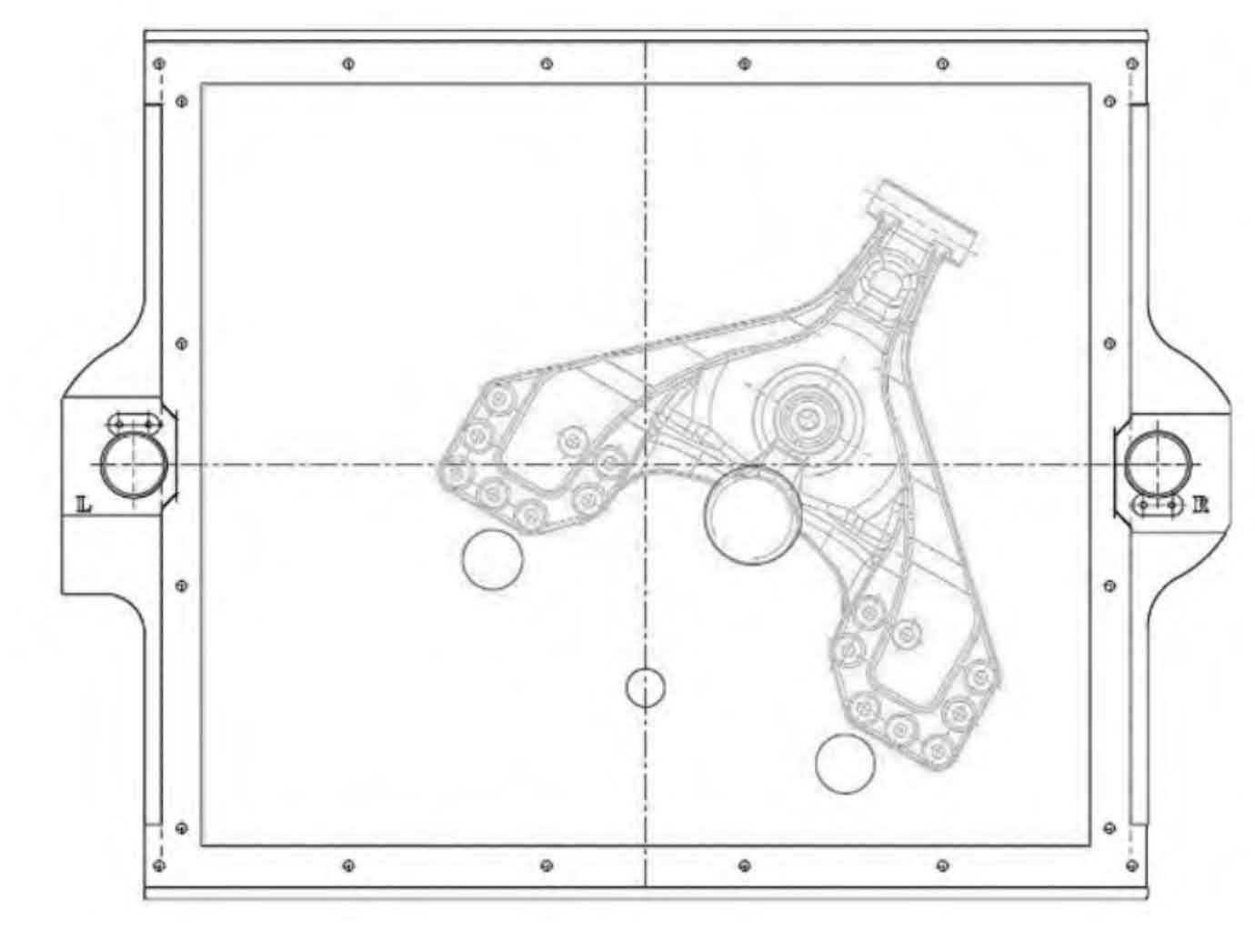

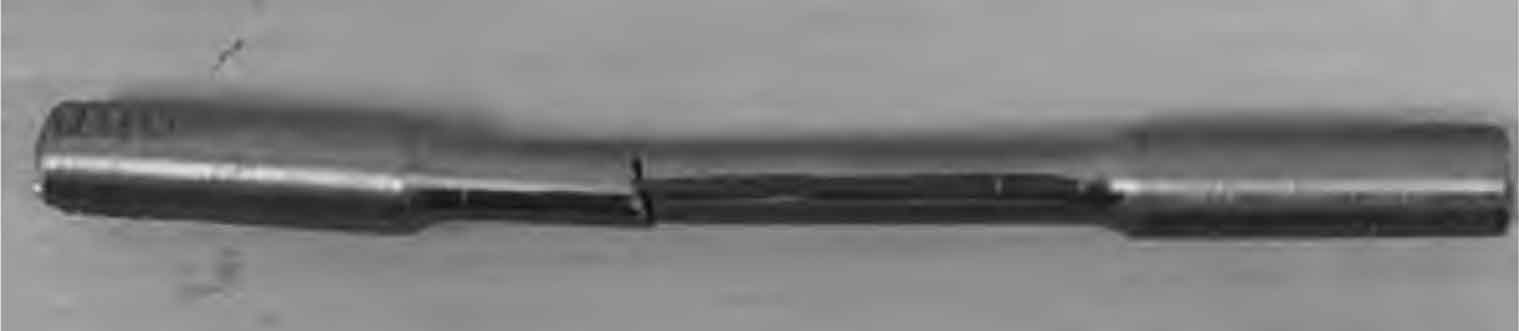

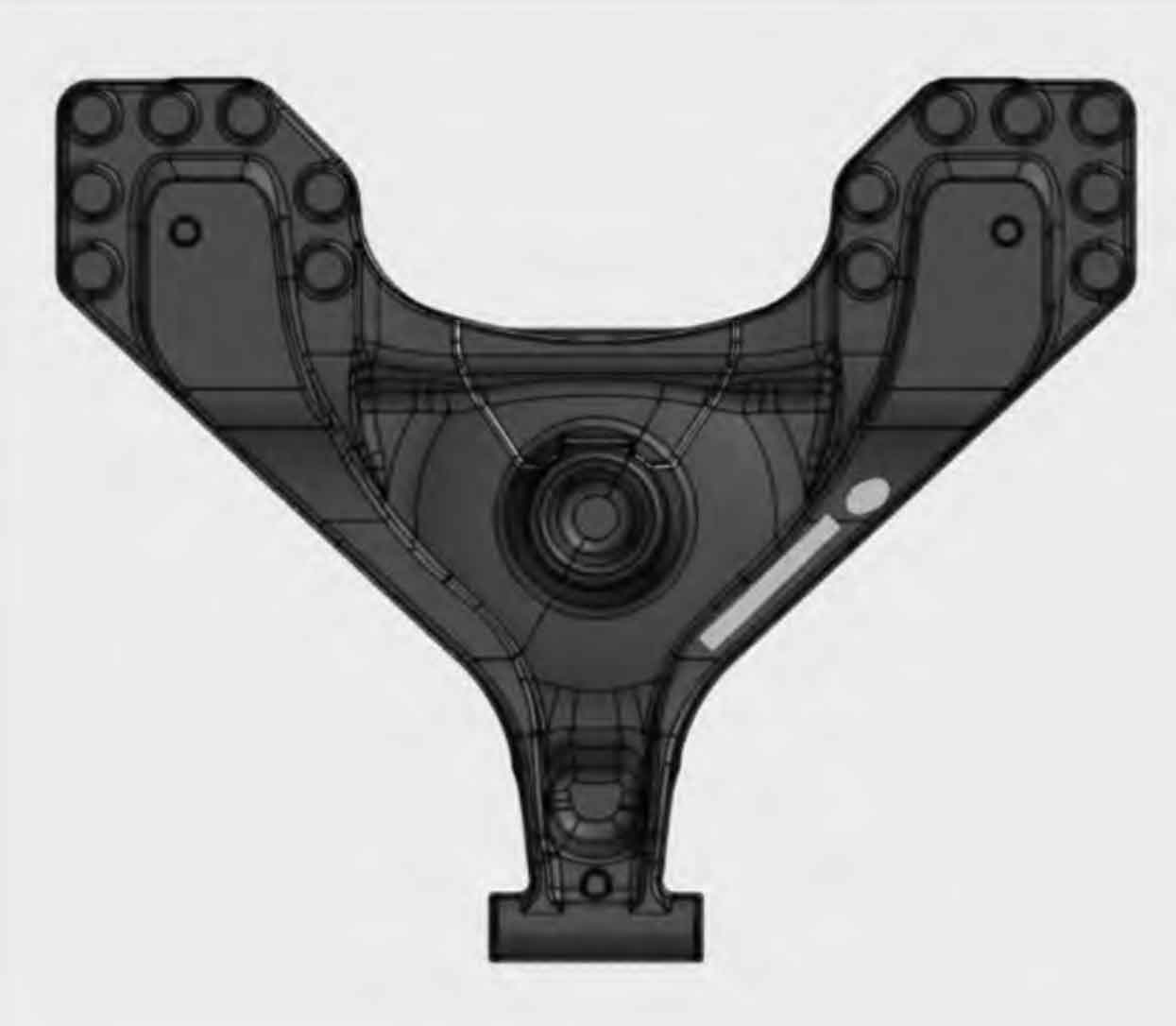

Trial production of nodular cast iron castings is carried out. Figure 1 shows the casting mold. The mechanical properties of nodular cast iron castings are tested by taking samples from the body. The sampling positions of tensile samples (Fig. 2) and metallographic samples (Fig. 3) are shown in Fig. 4. The performance data are shown in the table. The body tensile strength is > 800 MPa, the elongation is > 5%, the spheroidization grade is Grade 3, the graphite size is Grade 6 (Fig. 5), and the volume fraction of pearlite is 80% (Fig. 6), which meet the technical requirements.