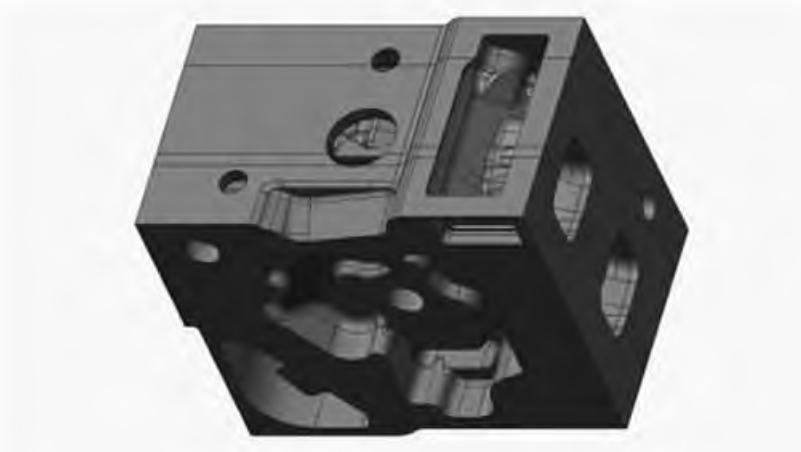

As automotive emission standards escalate, the imperative for lightweighting intensifies. Statistical analyses reveal domestic passenger vehicles exceed international counterparts by 8-10% in weight, while commercial vehicles surpass by 10-15. Research demonstrates that a 10% reduction in vehicle mass improves fuel efficiency by 6-8%. This paradigm shift drives replacement of ferrous components with aluminum alloys across powertrains, particularly in new energy vehicles. Within this landscape, mastering the casting process for geometrically intricate aluminum components becomes paramount for defect mitigation and performance optimization.

Material Composition, Modification Control and Purification

Alloy composition critically influences microstructure and mechanical properties. Conventional elements are monitored via direct-reading spectrometers for rapid precision. In Al-Si systems, trace elements (Ti, Zr, V) enhance fluidity and refine grains through intermediate alloys. The grain refinement efficacy follows Hall-Petch strengthening:

$$\sigma_y = \sigma_0 + kd^{-1/2}$$

where \(\sigma_y\) is yield strength, \(\sigma_0\) is lattice friction, \(k\) is the strengthening coefficient, and \(d\) is grain diameter. ZL104 alloys leverage Mg2Si precipitation hardening, demanding stringent Mg control (typically 0.2-0.5 wt%) for optimal tensile/elongation balance.

Harmful impurities—notably Fe—form deleterious intermetallics like β-Al9Fe2Si2 needles that degrade mechanical and corrosion properties. Iron content must be suppressed below 0.15-0.25 wt% through:

- Charge material selection

- Crucible/tool contamination protocols

- Rotary degassing with N2 or Argon:

$$C_t = C_0 e^{-kDt}$$

where \(C_t\) is hydrogen concentration at time \(t\), \(C_0\) is initial concentration, \(k\) is kinetic constant, and \(D\) is diffusion coefficient.

Modification parameters dictate eutectic silicon morphology:

| Parameter | Range | Effect |

|---|---|---|

| Modifier (Sr) | 0.02-0.04 wt% | Transforms acicular Si → fibrous |

| Temperature | Tpouring + 10°C | Higher T accelerates reaction; >750°C increases oxidation |

| Time | 10-20 min | Insufficient: incomplete modification; Excessive: fading |

Casting Process Parameters Optimization

Critical variables governing the casting process include pouring temperature, velocity, cooling rate, and solidification sequence. Empirical relationships govern these parameters:

Pouring Temperature (Tp)

Defined as: \(T_p = T_{liquidus} + \Delta T\) where \(\Delta T\) = 70-100°C for gravity casting. Complex geometries demand adjustments:

- Thin sections (<4mm): Tp ≈ 760°C for enhanced fluidity

- Thick sections (>15mm): Tp ≈ 710°C to minimize shrinkage

Deviation risks defects:

$$T_p \text{ too low} \rightarrow \text{cold shuts, misruns}$$

$$T_p \text{ too high} \rightarrow \text{gas porosity, shrinkage, hot tears}$$

Cooling Rate (CR)

Governing microstructure refinement and defect suppression:

$$CR = \frac{\Delta T}{\delta x} \cdot \alpha$$

where \(\alpha\) is thermal diffusivity, \(\Delta T\) is temperature gradient, and \(\delta x\) is characteristic length. Water-cooled dies maintain CR > 5°C/s, achieving:

- Dendrite Arm Spacing (DAS) reduction: DAS ∝ CR-n (n≈0.33)

- Microporosity mitigation

| Cooling Method | Thermal Conductivity (W/m·K) | Application |

|---|---|---|

| Copper chills | 390 | Local heavy sections |

| Cast iron chills | 55 | Core-mounted cooling |

| Water channels | – | Die temperature control (25±3°C) |

Pouring Methodology Selection

Complex internal geometries necessitate sand/salt cores, favoring gravity pouring. Tilt-pour systems provide critical advantages:

- Laminar flow minimizing turbulence

- Sequential cavity filling reducing gas entrapment

- Directional solidification enhancing feeding

Computational simulation (e.g., PROCAST) optimizes tilt parameters:

$$V_{fill} = k \cdot \theta \cdot \frac{dA}{dt}$$

where \(V_{fill}\) is filling velocity, \(\theta\) is tilt angle, \(A\) is cross-sectional area, and \(k\) is alloy constant.

| Casting Method | Mold Cost | Porosity | Heat Treatability | Production Rate |

|---|---|---|---|---|

| High Pressure | High | High | No | High |

| Low Pressure | Medium | Low | Yes | Medium |

| Gravity | Low | Low | Yes | Low |

Integrated Process Control

Thermal Management

Differential die temperatures govern solidification gradients: \(T_{top} = T_{bottom} + (20 \text{ to } 30)°C\). This bias:

- Promotes bottom-to-top freezing

- Redirects shrinkage to risers

- Minimizes hot spots

Coatings Engineering

Die coating thickness (\(\delta_c\)) follows strategic zoning:

$$\delta_c =

\begin{cases}

200-300 \mu m & \text{thin sections} \\

50-100 \mu m & \text{riser contacts} \\

<50 \mu m & \text{high-stress radii}

\end{cases}$$

Functions include thermal insulation, lubricity, and surface finish control. Zirconia-based coatings withstand >800°C without degradation.

Rhythm Stability

Consistent cycle times (\(t_c\)) maintain thermal equilibrium:

$$t_c = t_{pour} + t_{solidify} + t_{eject} \pm 5\%$$

Deviation >10% necessitates die reconditioning to stabilize the casting process. Automated cycles regulate \(t_c\) within 2% tolerance.

Conclusion

Optimizing complex aluminum castings requires synergistic control across metallurgical preparation and the casting process. Key leverage points include: Sr-modification within 0.02-0.04 wt%, hydrogen reduction to <0.15 ml/100g Al, tilt-pour parameterization via simulation, and thermal gradient management through chills/die temperatures. Implementing these measures reduces scrap rates by 40-60% while achieving mechanical properties satisfying ASTM B26/B108 standards. Future advancements will integrate real-time process monitoring with adaptive control algorithms for zero-defect manufacturing.