Abstract

The quality control measures for key steel castings utilized in Electric Multiple Unit (EMU) trains. It introduces the technical specifications, surface quality requirements, and internal quality standards for these castings. By examining the prevention and control processes for defects such as excessive magnetic mark defects, slag porosity, and invasive porosity, the paper elucidates the process measures essential for ensuring casting quality. The use of tables and diagrams enhances the readability and comprehension of the technical details.

1. Introduction

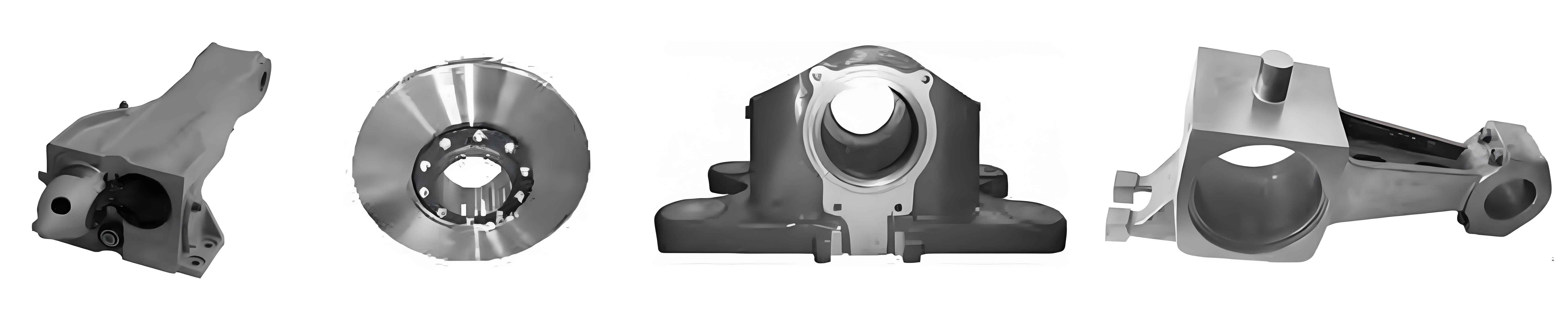

With the rapid development of high-speed rail transportation, the quality requirements for components in high-speed EMUs, particularly key steel castings, have been continuously elevated. The Chinese high-speed rail industry adheres to a “zero-tolerance for defects” and “zero-defect” mindset, emphasizing the importance of flawless components. Key steel castings in high-speed EMUs include coupler assemblies, buffers, brake discs, mounting brackets, and axle boxes. This paper discusses the technical requirements for these castings and the quality assurance measures implemented to meet these stringent standards.

2. Technical Requirements for Key Steel Castings

2.1 Material Specifications

The material specifications are crucial as they relate to the overall performance of the steel castings. For instance, brake discs experience significant thermal energy during braking, and their resistance to thermal shock and high-temperature stability depends on the material’s properties. This necessitates tight control over chemical composition, including oxygen content ≤0.010%, hydrogen content ≤0.00005%, and nitrogen content ≤0.015%. Additionally, mechanical properties such as tensile strength ≥1050 MPa and elongation after fracture ≥8% are required. Non-metallic inclusions must be limited to Type II and Type IV inclusions not exceeding Grade 1.

Table 1: Material Specifications for Key Steel Castings

| Property | Specification |

|---|---|

| Oxygen Content | ≤0.010% |

| Hydrogen Content | ≤0.00005% |

| Nitrogen Content | ≤0.015% |

| Tensile Strength | ≥1050 MPa |

| Elongation after Fracture | ≥8% |

| Non-Metallic Inclusions | Type II & IV ≤ Grade 1 |

2.2 Surface Quality Requirements

The aesthetic appeal and durability of key steel castings are crucial. Surface defects can significantly impact the corrosion resistance, fatigue resistance, and overall lifespan of the castings. For instance, axle box castings, which are subject to fatigue loading, must meet stringent surface quality standards. Defects such as dispersed non-crack defects with diameters not exceeding 1.5 mm and depths not exceeding 2 mm are permissible, with no more than three defects per 100 cm², and specific spacing requirements from edges or holes.

Table 2: Surface Quality Standards for Key Steel Castings

| Defect Type | Dimension Limit | Quantity Limit | Spacing Requirements |

|---|---|---|---|

| Dispersed Non-Crack | Diameter ≤ 1.5 mm, Depth ≤ 2 mm | ≤3 per 100 cm² | ≥10 mm from edges, ≥20 mm spacing |

2.3 Internal Quality Requirements

The internal quality of key steel castings directly relates to train safety. Radiographic and ultrasonic testing are used to ensure compliance with internal quality standards. For axle box castings, radiographic testing must not exceed ASTM E446 Class A, B, or C level 2 defects, with no Class D, E, F, or G defects allowed. Brake discs must meet TB/T 2980-2014 standards, with no porosity defects larger than a 2 mm equivalent flat-bottomed hole within 12 mm from the friction surface.

Table 3: Internal Quality Standards for Key Steel Castings

| Component | Testing Method | Defect Limitation |

|---|---|---|

| Axle Box | Radiographic | ≤ASTM E446 Class A, B, C level 2; No Class D, E, F, G defects |

| Brake Disc | Ultrasonic | No porosity defects > 2 mm equivalent flat-bottomed hole within 12 mm from friction surface |

3. Quality Assurance Measures for Key Steel Castings

3.1 Steel Liquid Quality Control

Steel liquid quality is crucial, with challenges such as ineffective final deoxidization and insufficient purity. Total oxygen content is an indicator of steel liquid quality, affecting the number, size, shape, and distribution of non-metallic oxide inclusions. High-quality low-phosphorus and low-sulfur scrap steel is used, with industrial pure iron added for products with very low P and S content requirements. Bottom-blowing argon and wire feeding refining techniques reduce the number and size of non-metallic inclusions.

Table 4: Steel Liquid Quality Control Measures

| Measure | Description |

|---|---|

| Scrap Steel Quality | Use high-quality low-P, low-S scrap steel; add industrial pure iron as needed |

| Bottom-Blowing Argon | Reduce non-metallic inclusions by argon bubbling |

| Wire Feeding | Further refine steel liquid to reduce inclusions |

3.2 Surface Quality Control

Surface quality is critical for key steel castings. For castings allowing welding repairs, all surface defects should be addressed before final heat treatment. For those not allowing welding repairs, strict process design and operational control are essential. Defects such as excessive magnetic mark defects and slag porosity are addressed through comprehensive measures.

3.2.1 Excessive Magnetic Mark Defects

Magnetic particle inspection is conducted before delivery. Defects exceeding the standard (single length ≤2 mm, cumulative length ≤4 mm) are unacceptable. Microshrinkage defects, identified through metallographic analysis, were addressed by adhering to sequential solidification principles and increasing the temperature gradient in affected areas.

Table 5: Measures to Address Excessive Magnetic Mark Defects

| Defect Type | Cause | Solution |

|---|---|---|

| Microshrinkage | Sequential solidification issues | Adhere to sequential solidification principles; increase temperature gradient in affected areas |

3.2.2 Slag Porosity Defects

Slag porosity defects are common, appearing on the upper surface of the pouring position, below cores, or in dead corners. Process design and manufacturing processes are strictly controlled to prevent these defects. Pouring system design is optimized using MAGMA software simulations to ensure smooth filling and prevent turbulence. Filters are used to block slag and stabilize the flow.

Table 6: Measures to Prevent Slag Porosity Defects

| Measure | Description |

|---|---|

| Pouring System Design | Ensure smooth filling and optimize using MAGMA simulations |

| Filters | Use filters to block slag and stabilize flow |

| Steel Liquid Quality | Control steel liquid quality and pre-pouring time |

3.3 Internal Quality Control

Internal defects primarily include shrinkage and porosity. For shrinkage defects, good feeding conditions and sequential solidification are ensured through process design. For porosity defects, which can be classified as intrusive, reactionary, or exudative, specific measures are taken. Intrusive porosity defects in brake discs were addressed by reducing gas emissions from molds and cores and improving ventilation.

Table 7: Measures to Address Internal Defects

| Defect Type | Cause | Solution |

|---|---|---|

| Shrinkage | Poor feeding conditions | Ensure good feeding conditions and sequential solidification |

| Intrusive Porosity | Gas emissions from molds and cores | Reduce gas emissions; improve ventilation |

4. Case Studies

4.1 Tight Lock Coupler Shrinkage and Porosity Defects

MAGMA software simulations were used to optimize the feeding system, adopting multiple small insulating risers, chromium ore sand cores, and anti-crack ribs. This improved the casting’s internal quality, with a finished product rate of 97%.

4.2 Brake Disc Outer Circular Surface Defects

Intrusive porosity defects were identified on the brake disc’s outer surface. Improvements included using new sand for the mold’s facing layer, optimizing the core sand formula, and enhancing ventilation in the mold and core.

5. Conclusion

The high quality requirements for key steel castings significantly increase the complexity of process design and production control. Utilizing casting solidification simulation software, adopting open pouring systems, ensuring stable filling processes, and maintaining adequate feeding conditions are crucial. New materials such as low-gas-emitting coated sand and high-efficiency risers should be used. Intelligent and digital equipment minimizes manual intervention. Enhanced process monitoring and inspection, possibly with visualization technology, ensures real-time, online, and rapid quality assessment.