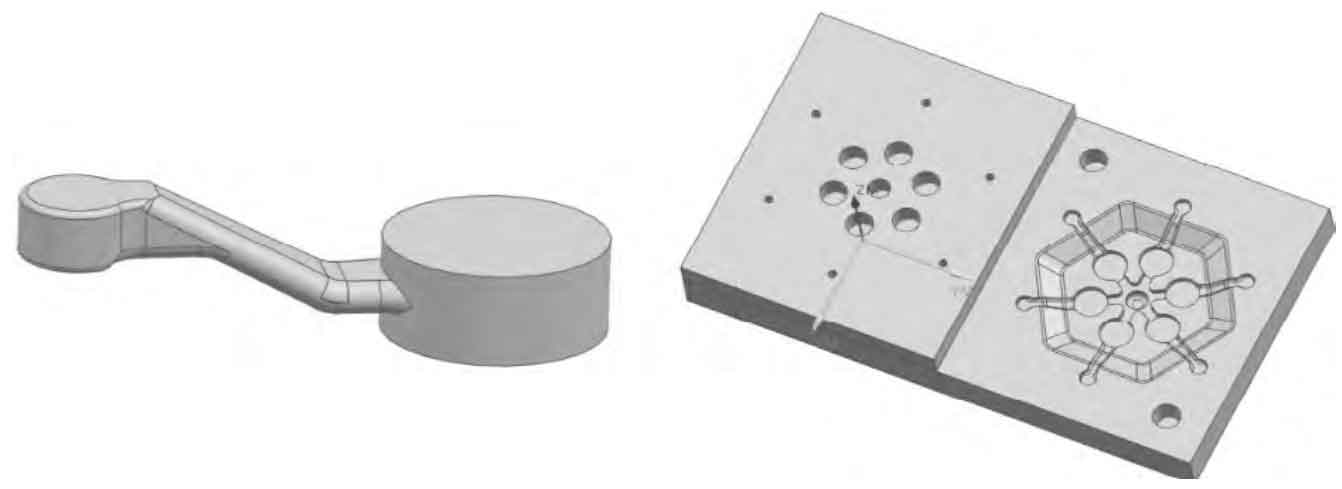

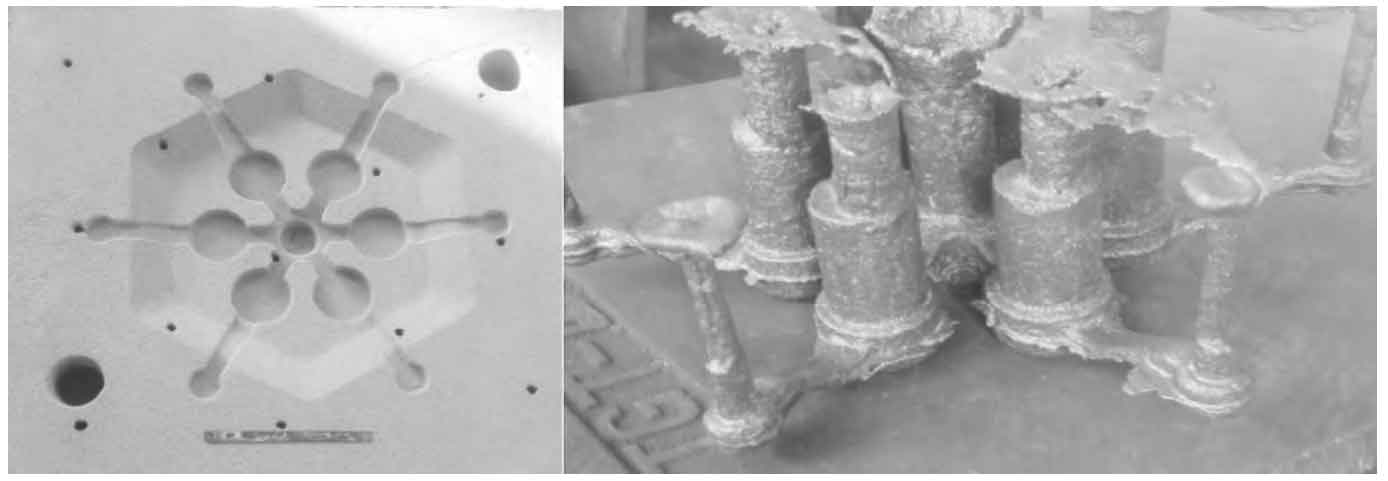

1. Water glass sand mold pouring test

Figure 1 shows the water glass sand mold pouring test of the brake arm of a tractor, with the casting size of 160 mm × 60 mm × 60 mm, material ZG45, single piece weight 0.85 kg. Using the traditional casting process, it takes at least 30 days from drawing design to metal mold production and commissioning, to sand mold (core) forming, and finally to blank pouring and cleaning, at a cost of 3880 yuan. Using digital dieless casting forming technology, it only takes 2 days from drawing design to direct processing and forming of sand mold (core) and finally to casting and cleaning of blank parts. The cost is 950 yuan, the cycle is shortened by 93% and the cost is saved by 75%. In this test, a box of 12 pieces is designed, and a total of 2 boxes are poured. There is no waste, and the surface roughness is ra 25 μ m. The dimensional tolerance is CT10, and the surface quality and dimension of the casting meet the drawing requirements of the product.

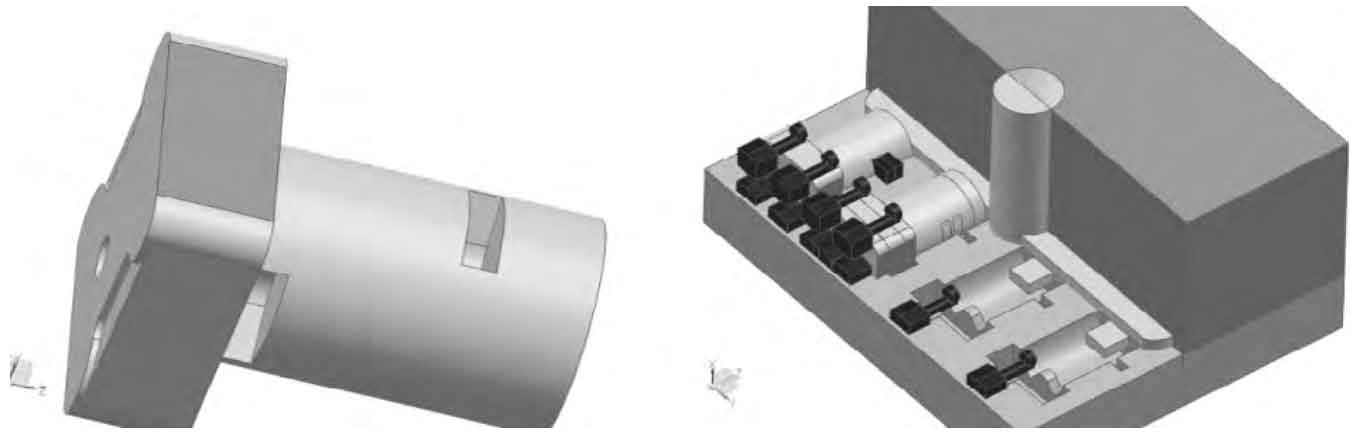

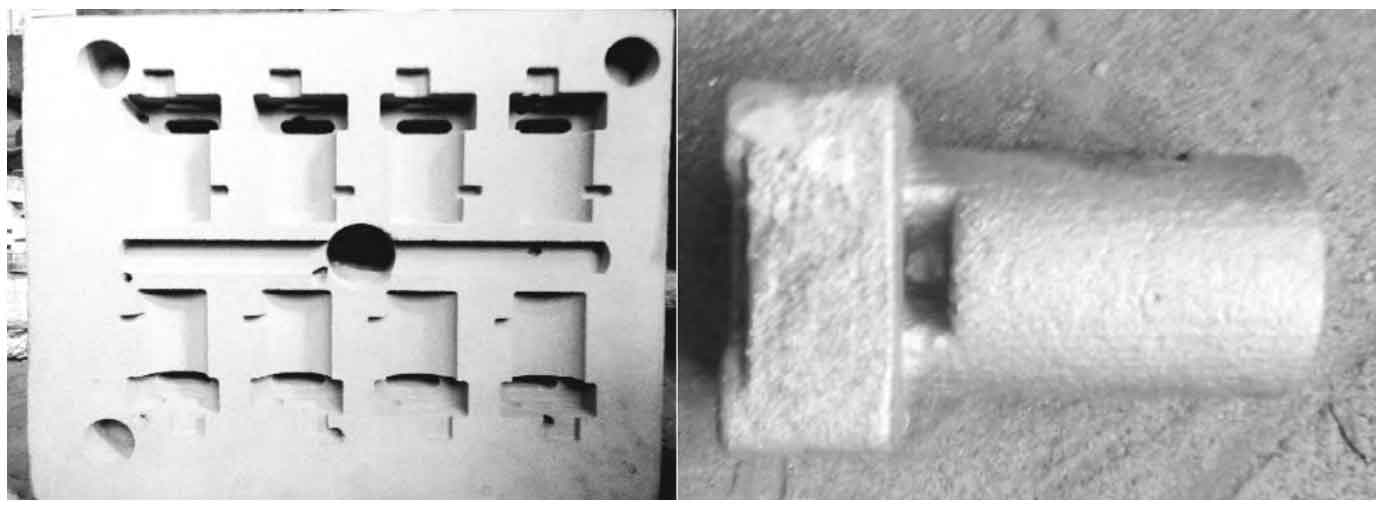

2. Resin sand mold pouring test

Fig. 2 is a resin sand mold pouring test of a tractor distributor shell, with a casting size of 90 mm × 90 mm × 130 mm, material ZG45, single piece weight 4.7 kg. Using the traditional casting process, it takes at least 30 days from drawing design to metal mold production and commissioning, to sand mold (core) forming, and finally to blank pouring and cleaning, at a cost of 5080 yuan. Using digital dieless casting forming technology, it only takes 4 days from drawing design to sand mold (core) direct forming, and finally to blank pouring and cleaning. The cost is 1400 yuan, the cycle is shortened by 86.7%, and the cost is saved by 72.2%. In this test, a box of 8 pieces is designed, and a total of 2 boxes are poured. There is no waste, and the surface roughness is ra 25 μ m. The dimensional tolerance is CT10, and the surface quality and dimension of the casting meet the drawing requirements of the product.

The direct forming of mold core is realized by processing sodium silicate sand block and phenolic resin sand block. The dimensional accuracy of sodium silicate sand mold (core), resin sand mold (core) and casting obtained by rapid processing is within 0.5 mm, and the surface of casting is smooth and smooth, with roughness Ra 25 μ m. The surface quality and size meet the drawing requirements of the product, and the performance meets the processing requirements. Using the method of one box with multiple parts, the manufacturing of small parts with demand less than 16 can be completed through 1 ~ 2 boxes, without waste.