Abstract: The structure of shell casting of a machine and the technical difficulties of investment casting were analyzed. The casting defects such as porosity, cold isolation, size aberration, and deformation were solved by reasonable formulation of process plans and parameters of mold making, shell making, melting, and pouring. The improved process can not only improve the casting quality of this part but also provide a reference for the development and optimization of the investment casting process of this type of part.

1. Introduction

Shell castings play a crucial role in aerospace engines as supporting components. These castings feature complex structures and varying wall thicknesses, often fabricated using the investment casting process with K403 high-temperature alloy. However, K403 alloy is prone to defects such as cracks, porosity, and insufficient filling during solidification. The castings demand precise dimensions, high metallurgical quality, and robust comprehensive mechanical properties, posing significant challenges for casting process design and manufacturing.

In initial developmental trials, issues such as unstable metallurgical quality, significant dimensional deviations, and porosity severely hindered production progress. Therefore, this study conducted experimental research on process parameters for mold making, shell making, melting, and pouring to address casting porosity and dimensional deviations. The research ultimately identified improvement solutions and optimal process parameters.

2. Analysis of Casting Structure and Technical Difficulties

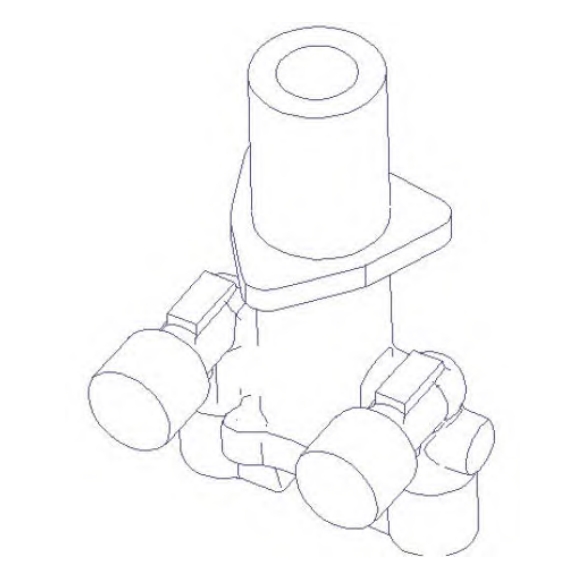

The shell casting employs K403 alloy, obtained through vacuum melting and pouring. The alloy composition is presented in Table 1. The casting boasts a complex structure, with a pillar height of 129 mm, a length of 111 mm, a maximum diameter of 32 mm, a minimum diameter of 14 mm, and a wall thickness of 6.5 mm (Figure 1). The casting exhibits significant variations in shape and thickness, numerous hot spots, and is classified as a highly challenging precision casting with no machining allowance.

Three primary technical challenges arise during production:

- The casting’s complex structure complicates mold removal and increases the risk of dimensional deformation.

- Structural constraints can lead to shell cracking, fire leakage, and burrs during pouring.

- Multiple hot spots make filling difficult, prone to defects such as porosity, cracks, and cold shuts.

40%

AI作图中

Table 1: Main chemical components of K403 high-temperature alloy

| Element | C | Cr | Co | W | Mo | Ti | Al | Content (%) |

|---|---|---|---|---|---|---|---|---|

| Range | 0.11~0.18 | 10.00~12.00 | 4.50~6.00 | 4.80~5.50 | 3.80~4.50 | 2.30~2.90 | 5.30~5.90 | |

| Element | Ce | Fe | Si | Mn | S | P | Ni | Content (%) |

| ——— | —- | —- | —- | —- | —- | —- | —- | ———— |

| Range | ≤0.01 | ≤2.00 | ≤0.50 | ≤0.50 | ≤0.01 | ≤0.02 | Balance |

3. Optimization of Casting Process and Results

Strict control of the mold-making process is crucial for obtaining high-quality wax molds. The pressing pressure and dwell time of the mold material significantly impact the precise shaping, dimensional accuracy, surface roughness, and elimination of surface sinks. Generally, appropriately high injection pressure and prolonged dwell time reduce mold material contraction, enhancing wax mold dimensional accuracy and surface roughness.

Key process parameters affecting wax mold pressing quality include wax material temperature, die temperature, injection pressure, and dwell time. Excessively low wax material temperature impairs fluidity, leading to defects such as cold shuts and insufficient filling. Conversely, too high a temperature increases material contraction, causing flow lines and sinks in the wax mold. Appropriately increasing injection pressure helps reduce wax mold shrinkage and improve dimensional accuracy. Excessive pressure compresses gases in the mold material, potentially causing sticking, cracks, and blisters; insufficient pressure results in incomplete edges and bubbles. Considering these factors, the wax material temperature was controlled between 55~63 °C, die temperature between 25~35 °C, injection pressure between 15~25 bar, and dwell time set at 15~20 seconds. Additionally, to address the issue of dimensional deviations observed during initial trials, the approach of assembling separate wax mold parts was abandoned. Instead, a new mold for integral wax pattern production was designed and manufactured, eliminating the potential for dimensional inaccuracies associated with assembly. This comprehensive adjustment in the mold-making process parameters and design significantly enhanced the quality and dimensional accuracy of the wax molds, paving the way for the production of higher-quality castings.

Furthermore, the optimization of wax mold size control measures ensured a more consistent and accurate wax pattern, reducing human error in the assembly process. The integrated mold design not only improved production efficiency but also minimized variations in the final casting dimensions, thereby enhancing overall product quality.

In summary, by meticulously controlling the key process parameters during the mold-making stage and adopting an innovative integral mold design, the study successfully overcame the challenges of dimensional inaccuracies and other defects in the production of K403 shell castings. These improvements not only met the stringent quality requirements for aerospace components but also set a precedent for future optimizations in investment casting processes for similar components.