Abstract

During the operation of large excavators (electric shovels, hydraulic shovels), the phenomenon of bucket teeth falling off is prone to occur, which in turn triggers failures in the crushing system. To ensure that falling bucket teeth are promptly detected, an electric shovel bucket teeth positioning monitoring system is designed. Based on existing wireless positioning monitoring technology for bucket teeth, this system thoroughly resolves the shortcomings of the original bucket teeth anti-loss warning system, such as inadequate battery endurance, weak signal strength, delayed alarm information, and insecure installation and fixation of the radio frequency (RF) signal transmitting device, by changing the signal alarm mode and the fixed installation method of the RF signal transmitting device. It can provide accurate and effective alarms for bucket teeth fracture and detachment, ensuring that drivers discover them in a timely manner and effectively avoiding failure shutdowns of the crushing station due to “jammed bucket teeth.”

1. Introduction

Large excavators, including electric shovels and hydraulic shovels, play a crucial role in mining operations. However, during their operation, the frequent occurrence of bucket teeth falling off or breaking poses a significant challenge. If not detected promptly, fallen bucket teeth can mix into the coal and enter the crushing station, causing considerable damage to crushing teeth, reducers, belts, and other crushing equipment, resulting in substantial economic losses for enterprises.

The Shengli Open-pit Mine of Shenhua Beidian Shengli Energy Co., Ltd. (hereinafter referred to as Shengli Open-pit Mine), located in the midwest of the Shengli Coalfield, faces frequent instances of bucket teeth falling off during coal mining operations using electric shovels and hydraulic shovels. In response to this issue, early attempts focused on optimizing the installation and fixation method of bucket teeth, which could effectively prevent bucket teeth loss due to wedge iron detachment but was unable to prevent loss caused by bucket teeth fracture. Later, a video monitoring system was installed on the electric shovels, utilizing a bucket teeth anti-loss warning system to monitor the usage of bucket teeth in real-time. However, due to operator negligence, timely detection of bucket teeth loss was sometimes not achieved. Additionally, material viscosity and humidity could cause material to adhere to the surface of bucket teeth, making it difficult for operators to assess the condition of bucket teeth through the monitoring system. Multiple faults involving jammed bucket teeth in the crushing station have occurred in actual production at Shengli Open-pit Mine. Therefore, there is an urgent need for a sensitive and accurate bucket teeth positioning monitoring system for mines employing the single-bucket excavator-truck-semi-mobile crushing station process.

2. Overview of the Original Bucket Teeth Anti-loss Warning System

2.1 System Composition and Working Principle

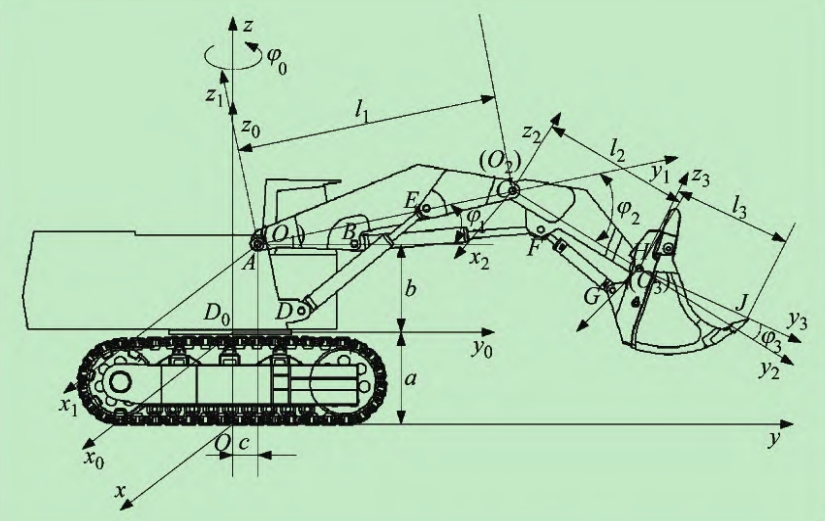

The original bucket teeth anti-loss warning system primarily consists of a signal receiving and processing device (main unit), multiple wireless positioning monitoring devices, and antennas. Through an independent hardware circuit, radio frequency technology, wireless communication technology, and azimuth sensors are integrated onto a single circuit board and controlled by software to monitor the bucket teeth of electric shovels in real-time. The main unit installed inside the cab receives signals transmitted in real-time by the wireless devices installed on each bucket tooth. The main unit inspects the online status of each bucket tooth and calculates the loss of bucket teeth based on the received signal strength.

2.2 Deficiencies of the Original System

(1) Installation and Fixation Issues

Due to the harsh operating environment of large excavators, the RF signal transmitting device is placed inside a metal casing with a thickness of 2mm, which is welded onto the surface at the end of the bucket tooth. During excavation, the metal casing welded onto the end of the bucket tooth is subject to impact and wear, leading to detachment, loss, or damage within a short period. Once the RF signal transmitting device detaches, monitoring of the bucket tooth at that location ceases. This installation and fixation method cannot achieve monitoring throughout the entire life cycle of the bucket tooth. Additionally, the device is relatively expensive, and loss or damage results in economic losses.

(2) Complexity in Battery Replacement and Maintenance

The metal casing of the RF signal transmitting device is fixed by welding. When replacing the battery, maintaining, or installing new bucket teeth, the metal casing needs to be cut off along the weld, which is cumbersome and time-consuming, affecting the efficiency of the electric shovel. Furthermore, during welding, high temperatures can adversely affect the RF signal transmitting device.

(3) Delayed Alarm Information

The alarm mode of the current bucket teeth anti-loss warning system is such that the main unit issues an alarm when it cannot detect the signal from the bucket teeth RF signal transmitting device. In this scenario, if a detached bucket tooth (with the RF signal transmitting device welded onto it) remains on the working face instead of being carried away by a truck, the main unit will still receive a signal, and the system will not immediately issue an alarm. The alarm is only triggered when the bucket tooth is carried away to a certain distance by the truck and the main unit can no longer detect its signal. Therefore, there is a lag in the alarm information.