In order to achieve feeding of the riser to the casting, it is necessary to ensure that the solidification time of the riser is greater than the solidification time of the casting, that is, if the modulus of the riser is greater than the modulus of the steel casting, the riser may solidify later than the casting, and it is possible to achieve feeding of the riser to the casting. The general condition for the riser to have sufficient liquid metal to replenish the casting or the volume of the part of the casting being replenished is. Similarly, the casting body also needs to have a corresponding feeding gradient.

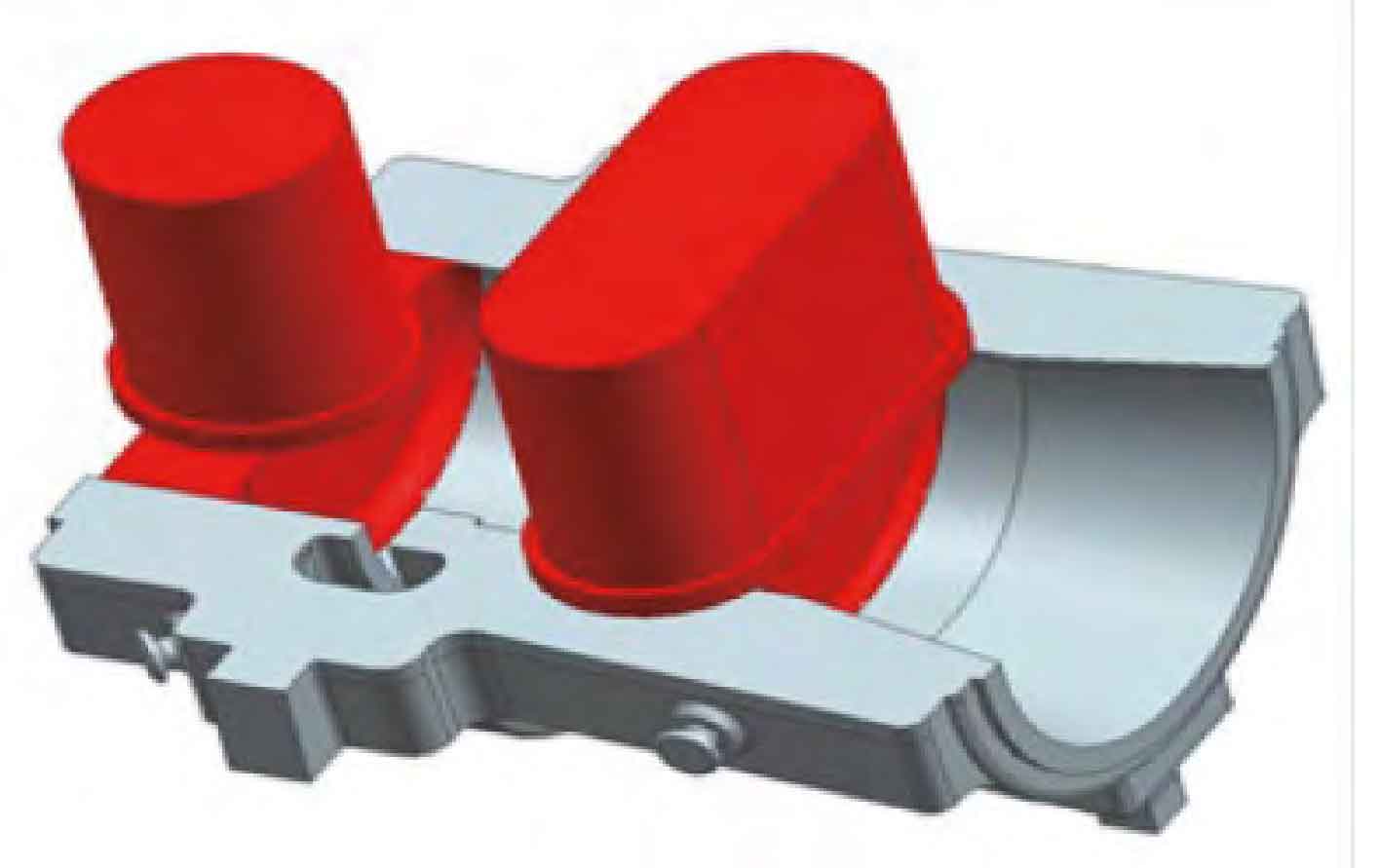

Based on the structural characteristics of the casting and the preliminary process plan, the parting surface position and riser position are basically determined. Then, through computer simulation and analysis of the location of hot spots in the casting, based on the distribution of hot spots in the casting, combined with horizontal feeding distance and modulus calculation, determine the location, size, and quantity of the riser, and cooperate with the use of subsidies and cold iron to ensure smooth feeding of molten steel; Determine the feeding efficiency of the insulation sleeve, calibrate the feeding liquid amount at the riser, and further determine the riser size. The wall riser scheme for this product’s process design involves setting a wall riser at the maximum hot spot of the back flange, and ultimately successfully completing the feeding of the back flange, as shown in the figure.