Iron mold sand coated casting process is a new net forming casting process. The metal mold cavity is covered with a thin layer of molding sand to form a mold. It has the characteristics of convenient and fast metal mold casting and good concession of shell mold casting. At the same time, it also has the characteristics of less demand for molding materials, small machining allowance, low stress in the casting, high dimensional accuracy of the casting, low scrap rate Advantages such as small workload of casting cleaning. With the maturity of technology, iron mold sand coating process has been developed rapidly and widely used. However, there are still many problems in production, such as: it is difficult to control the solidification process of crankshaft, and casting defects such as shrinkage porosity and shrinkage cavity will appear in the casting; It is difficult to modify each casting process because of the high cost of iron coating. Therefore, using computer to simulate the iron mold sand coating process of nodular cast iron crankshaft can effectively predict shrinkage defects, optimize process parameters and reduce waste.

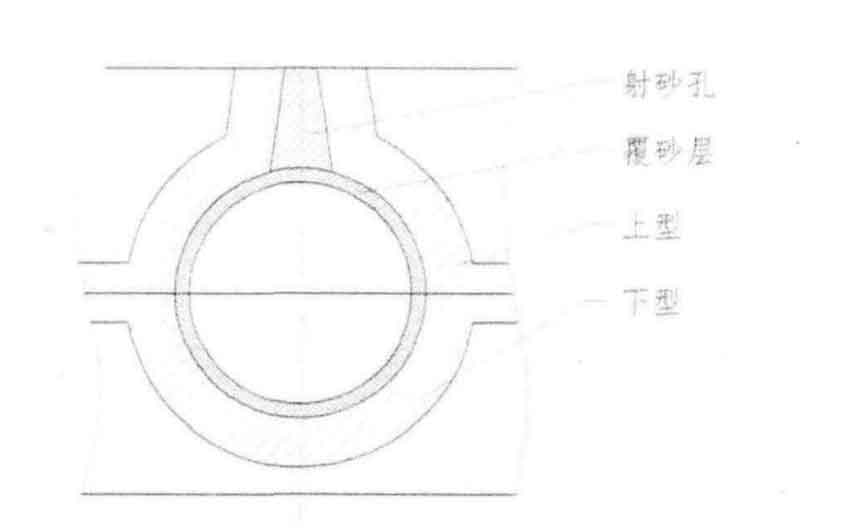

Iron mold sand coated casting production technology began in the 1970s. It is a special casting method developed by Chinese foundry workers on the basis of casting technology research at home and abroad and combined with China’s national conditions. This method combines the two technologies of metal model and sand mold (as shown in Figure 1). The sand mold is a cast iron cavity similar to the shape of the casting, which is used as the iron mold of the sand box, and covered with a layer of thick coated sand to form a sand tire for sparing the casting, and the thickness of the sand tire depends on the size and shape of the casting, It can ensure that the whole process is completed under an ideal condition to eliminate casting defects to the greatest extent, so as to improve the quality of castings.

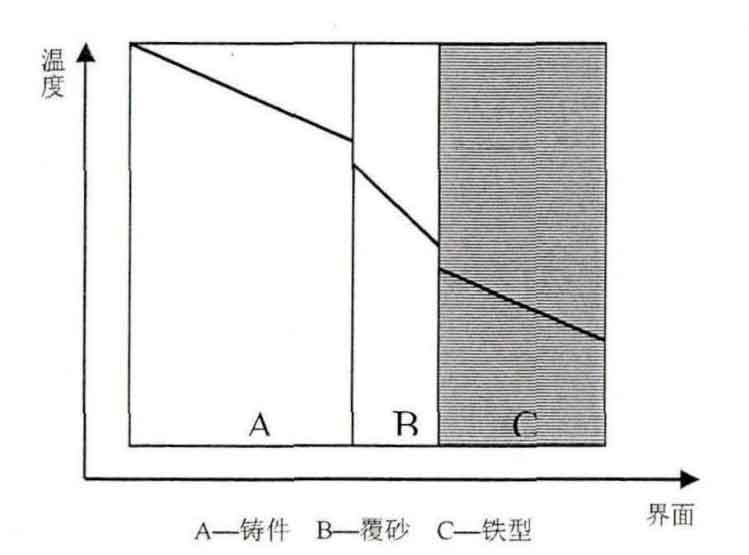

The characteristic of iron mold sand coating process is that there is a layer of sand coating in the middle, which makes it different from ordinary casting process. In the process of molten metal pouring, with the decrease of casting temperature, the temperature of sand layer and iron mold increases gradually. Only when the thickness of the sand layer is appropriate can it play a role. If the thickness of the sand layer is too large, the external iron mold will not play a role, which is equivalent to sand mold casting; If the sand layer is too thin and the cooling speed is too fast, it is equivalent to metal mold casting. Figure 2 shows the temperature distribution of iron mold sand coating process. When iron mold sand coated casting is used to produce various castings, the appropriate thickness is generally determined through test or empirical analogy and computer solidification simulation.