There are two main problems to be solved in the sand core structure design of low pressure inner cylinder.

(1) Solve the problem of mold lift angle and assembly interference at the volute steam passage

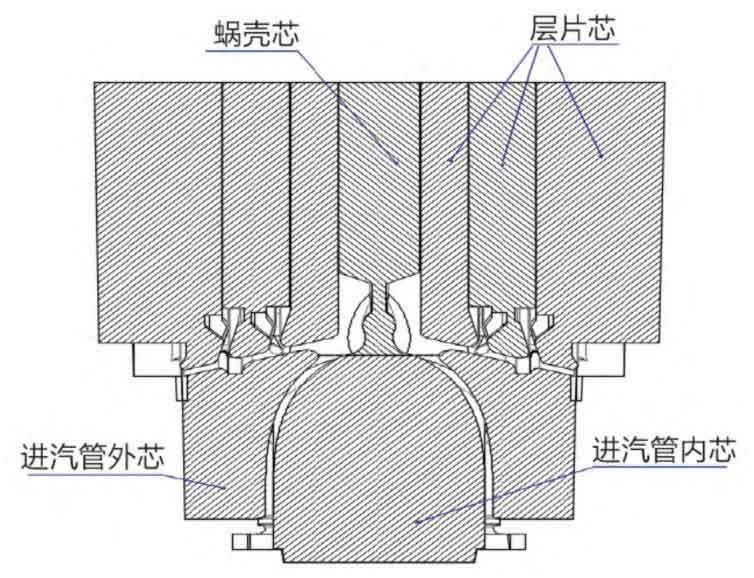

Cut the inner part of the steam inlet pipe and the steam passage part of the inner cavity, and make cores respectively; The outer part of the steam inlet pipe is cored along the center of the streamline for easy mold removal; When the box is closed, the sand core at the inner side of the steam inlet pipe shall be lowered first, then the sand core at the outer side of the steam inlet pipe shall be assembled, and finally the sand core at the inner cavity steam channel shall be assembled, which can simultaneously solve the problem of mold lift and assembly interference at the volute.

(2) Optimize the division, production and assembly mode of sand core between inner cavity partitions

Because the spacing of the inner cavity partition is too small and there is an included angle with the axis direction, the conventional idea of using the integral sand core is not feasible. After repeated analysis of the advantages and disadvantages, the final process adopts the layered sand core design scheme, which divides the inner cavity space into seven parts along the edge line of the diaphragm. Each part and the narrow and long area enclosed between different diaphragms together form a complete sand core, and the upper cantilever is designed to connect with it to play a fixed support role. During box closing, the sand core at the volute steam channel shall be lowered first, and then the laminated sand core assembly shall be completed to both sides in order to maximize the strength of the complex sand core and facilitate the detection and control of the box closing wall thickness in each area. The sand core structure section of ductile iron castings is shown in the figure.