The rotary disc is the key component on the spindle of drilling machine, which needs high precision and certain hardness. According to the use of sand mold casting rotary disc and the structural characteristics of sand mold casting rotary disc, the dovetail guide sliding surface and large plane shall not have any casting defects. The rotary disc is usually produced by sand mold gravity casting. The material of sand mold casting rotary disc is HT250. HT250 has high strength, good wear resistance, good vibration damping and better casting performance. Combined with ZHY casting’s inclined pouring production experience, combined with the structural characteristics of the part and continuous simulation and optimization, the pouring position, parting surface, inner sprue, pouring riser and cold iron position are determined, and finally the best sand mold casting process scheme of sand mold casting rotary disk is designed. It can provide technical reference for the production of relevant castings.

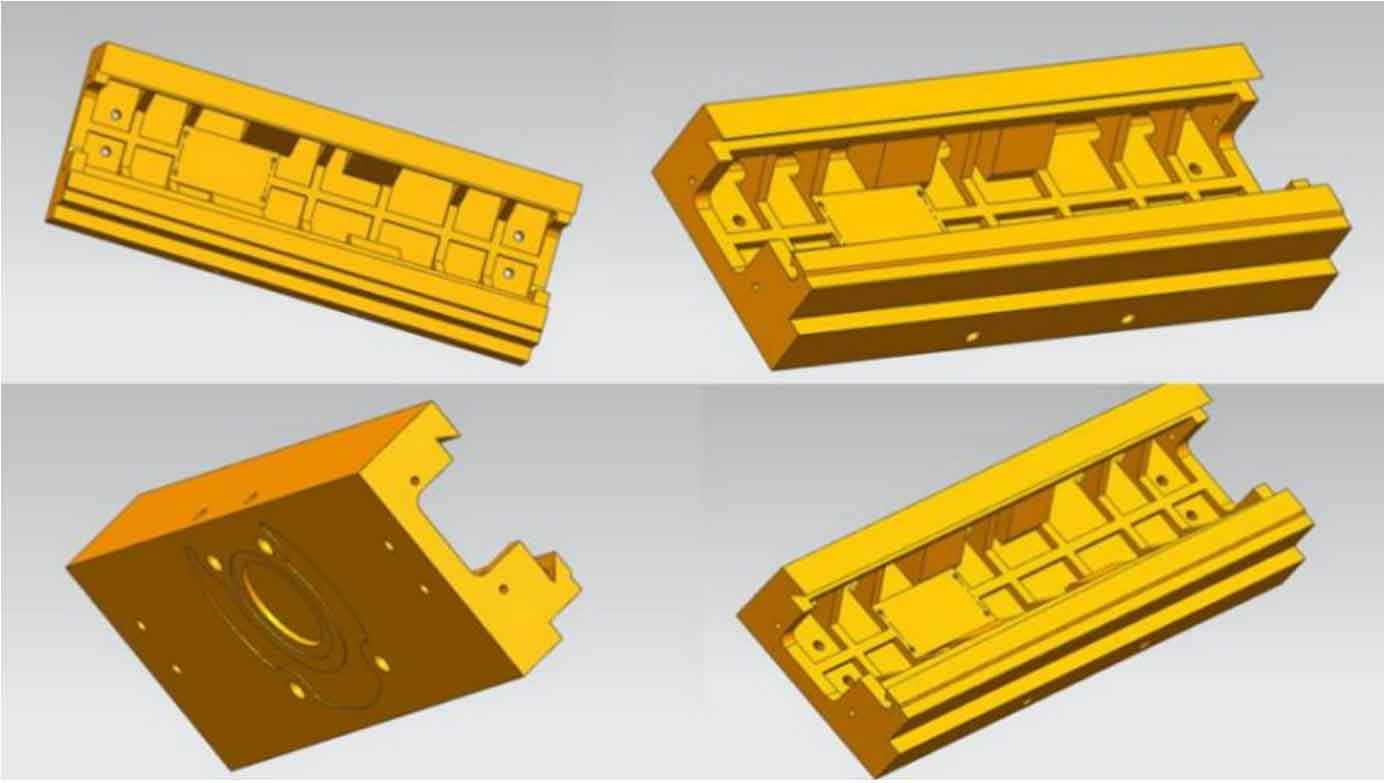

The three-dimensional part drawing of sand mold casting rotary table is shown in the figure, and the outline dimension of the part is 1040mm × 375 mm × 158 mm, the overall structure of sand mold casting rotary table is relatively symmetrical, and the interior is multi ribbed plate semi open porous structure; The maximum wall thickness is 30 mm, the minimum wall thickness is 10 mm, and the diameter of the smallest hole is 6 mm. It belongs to thin-walled medium-sized complex parts. In addition, the quality requirements of dovetail sliding surface and screw hole surface of sand mold casting rotary disc are high. Because there are many rib plates and multiple hole structures inside, making core making becomes the difficulty of the casting.

The numerical simulation can provide a good reference for the quality control and defect improvement of aluminum alloy die castings, and shorten the development time; Reasonable selection of high-speed switching point is an important basis to ensure good internal quality and surface forming of sand mold casting rotary disc; When adjusting the process parameters can not improve the product quality, the defect causes should be considered from the aspects of sand mold casting rotary disk structure, gating system and exhaust system; When there is no problem with the feeding, passing and discharging of products, the quality of sand mold casting rotary disc can be guaranteed.