The quenching medium used for nodular cast iron grinding ball should have the following two characteristics: 1) The quenching medium has a fast cooling rate at the high temperature stage of the grinding ball; 2) The quenching medium has a slow cooling rate at the low temperature stage of the grinding ball.

Among the common cooling mediums, the medium with fast cooling speed is water. When the grinding ball is quenched in water, the cooling speed is fast at the high temperature stage, but too fast at the low temperature martensite transformation zone will cause the grinding ball to crack; Traditional ductile iron grinding balls are quenched with quenching oil. Although the cooling rate is slow at low temperature, the cooling rate is not ideal at high temperature; The ideal quenching medium should have the same rapid cooling rate as water in the high temperature stage and the same slow cooling rate as quenching oil in the low temperature stage.

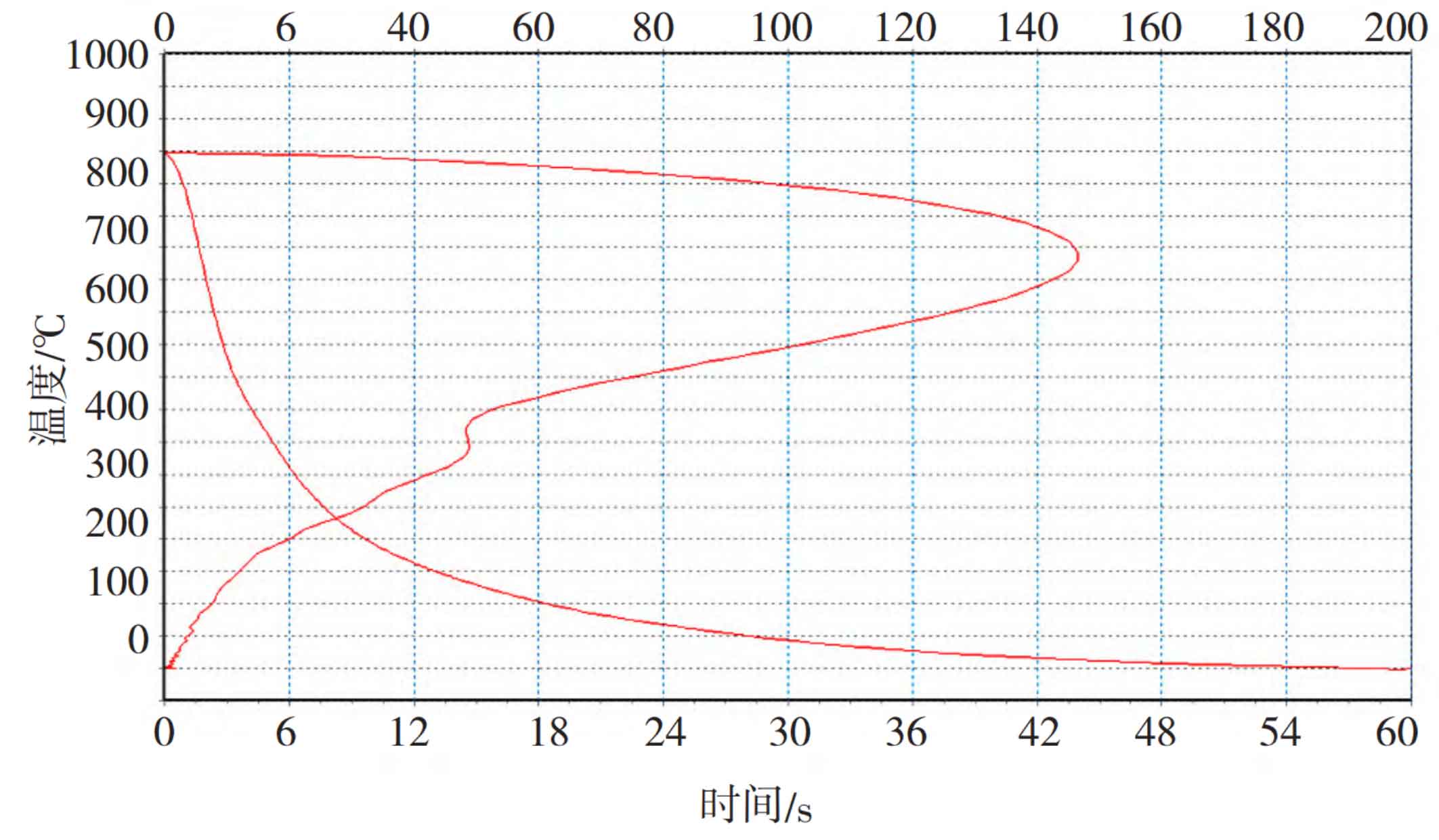

Water based quenching medium is a new type of quenching medium developed in recent years, which is generally high polymer, infinitely soluble in water. The cooling speed is fast in the high temperature stage of the grinding ball, and slow in the low temperature stage. The cooling data are shown in Figure 1 and Table 2. The water-based quenchant is a viscous liquid, white or yellowish in color, with a specific gravity of 1.05-1.1 slightly higher than that of water, and is weakly alkaline (PH value is 7-9) Due to the strong bonding force between molecular chains, it is not easy to break the chains during quenching and cooling, and it is resistant to aging and has a long service life. It is an excellent quenching medium for Si Mn alloyed ductile iron balls.

| Performance index | Measured value |

| Maximum cooling rate/℃ · s ^ – 1 | 146 |

| Temperature at maximum cooling speed/℃ | 689 |

| Cooling rate at 300 ℃/℃ · s ^ – 1 | 31.88 |

| Time to 600 ℃/s | 2.37 |

| Time to 400 ℃/s | 5.2 |

| Time to 200 ℃/s | 13.01 |

By controlling the concentration of water-based quenching medium, adjusting the temperature of quenching solution, controlling the quenching time and other means, the quenching process of Si Mn alloyed ductile iron grinding balls can meet the requirements of the transformation of the matrix structure of the grinding balls, so that the properties of the grinding balls can eventually reach or even exceed those of traditional ductile iron grinding balls.