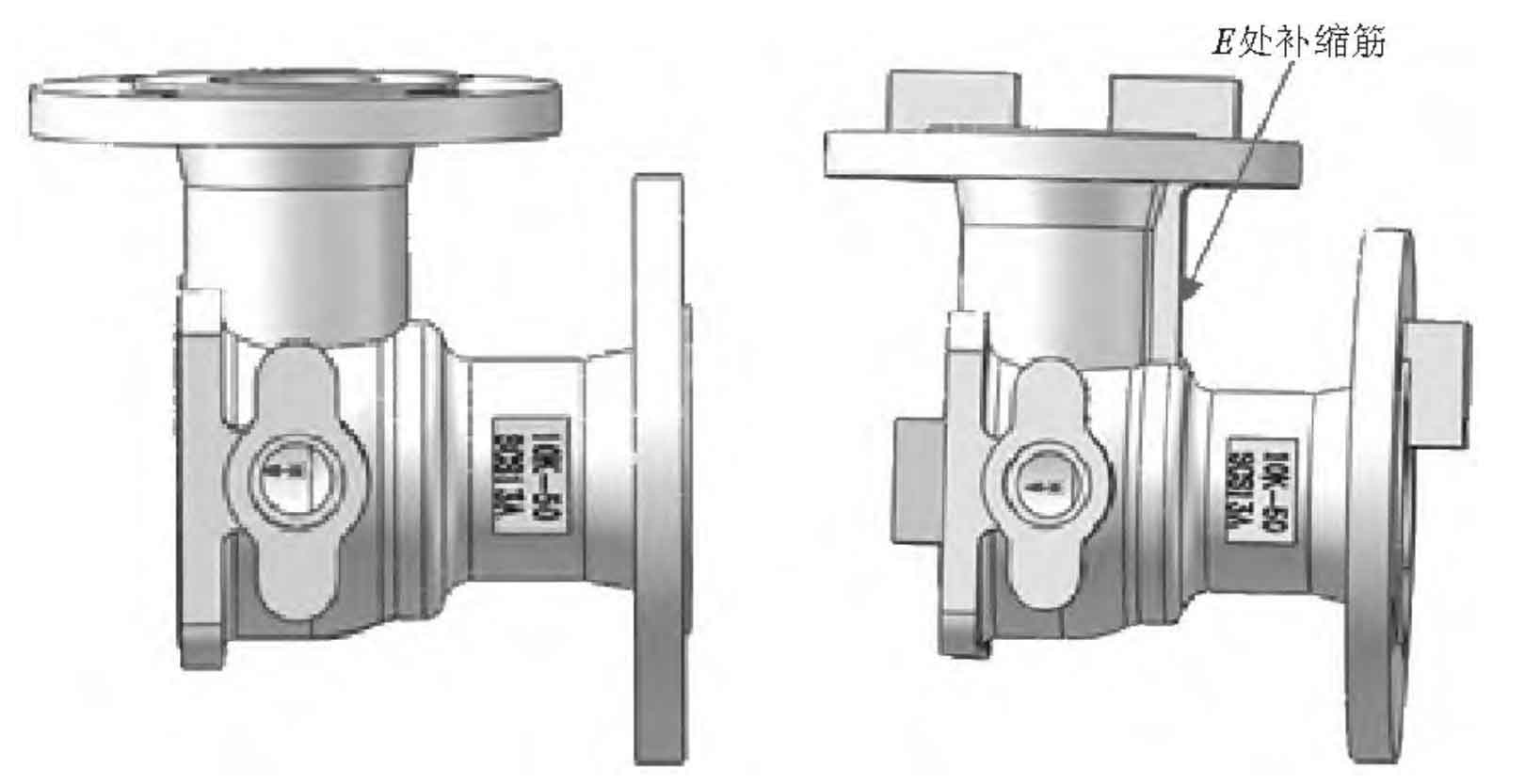

Figure 1 shows the flange bonnet casting with blocked feeding channel. There are shrinkage defects at A and B of the casting, and a large number of shrinkage defects at C after processing; Figure 2 shows the improved process plan. Aluminum silicate is used for thermal insulation at position D, and water immersion chilling treatment is carried out at the bottom flange position, which not only opens the feeding channel, but also enables the casting to achieve sequential solidification, thus avoiding shrinkage defects.

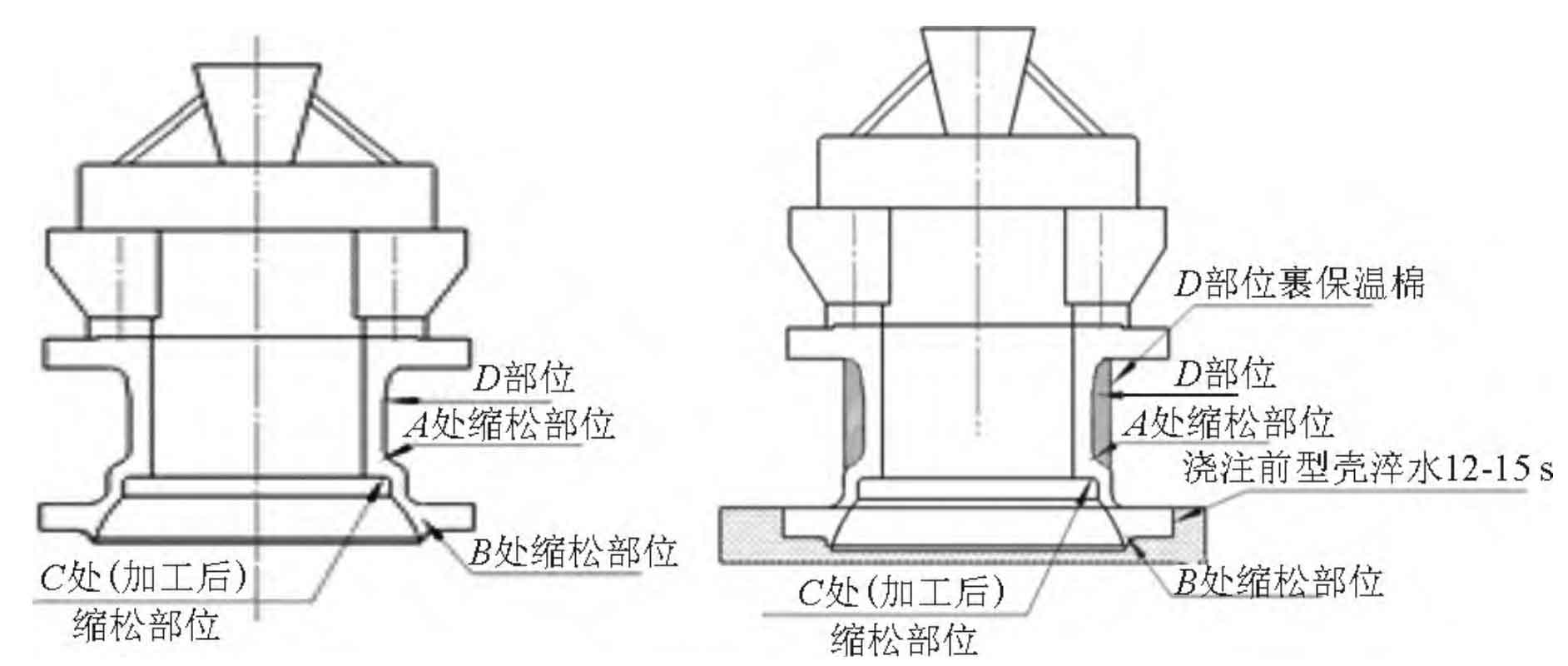

Figure 3 shows the shrinkage porosity defect at the hot spot inside the casting after pouring due to the uneven wall thickness of an L-shaped flange valve body. Figure 4 shows the improved process plan. The shrinkage reinforcement is added on the casting to open the shrinkage channel and eliminate the shrinkage defects.