The numerical simulation is carried out by AnyCasting software. The material is set as zg20simn, the pouring temperature is 1580 ℃, the pouring time is 28 s, the sand mold temperature is 25 ℃ and the sand core temperature is 25 ℃.

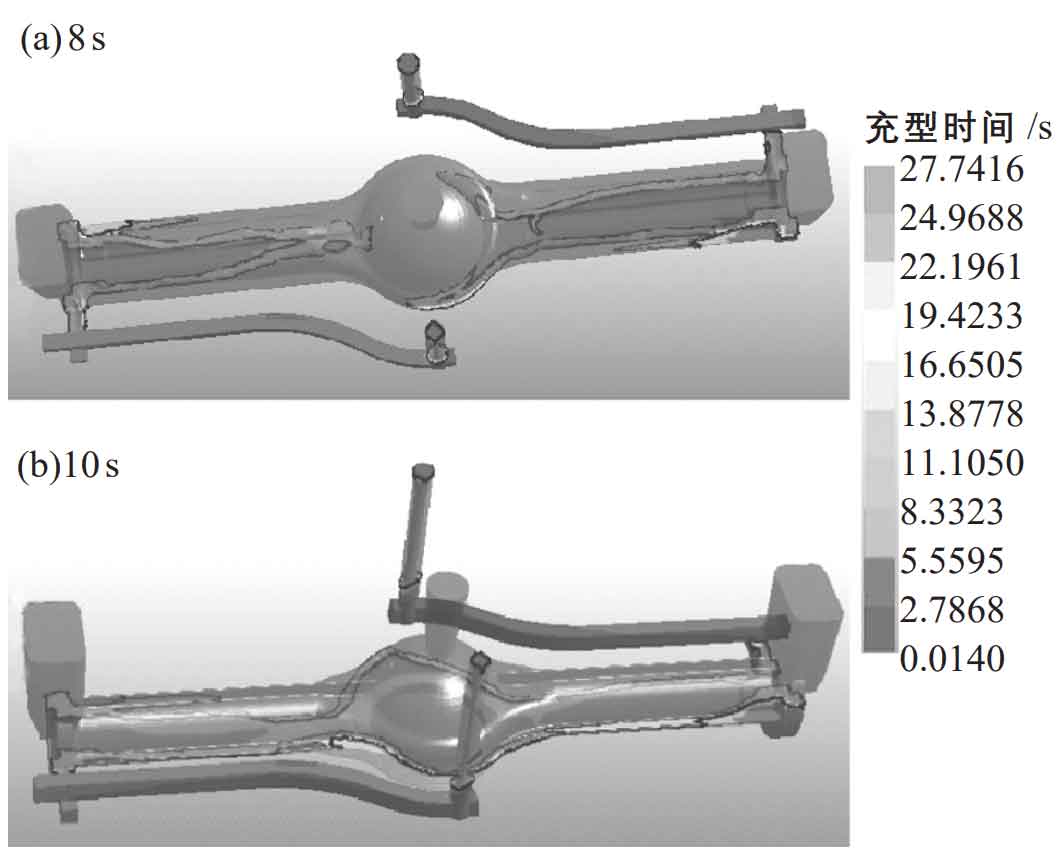

1. Analysis of mold filling process of excavator rear axle casting

The mold filling process of excavator rear axle casting is shown in Figure 1. When pouring to 8s, the liquid metal flows into the middle arc of the rear axle casting of the excavator; After pouring for 10s, the metal liquid flowing into the left and right sprues meets and collides and jumps at the middle arc position.

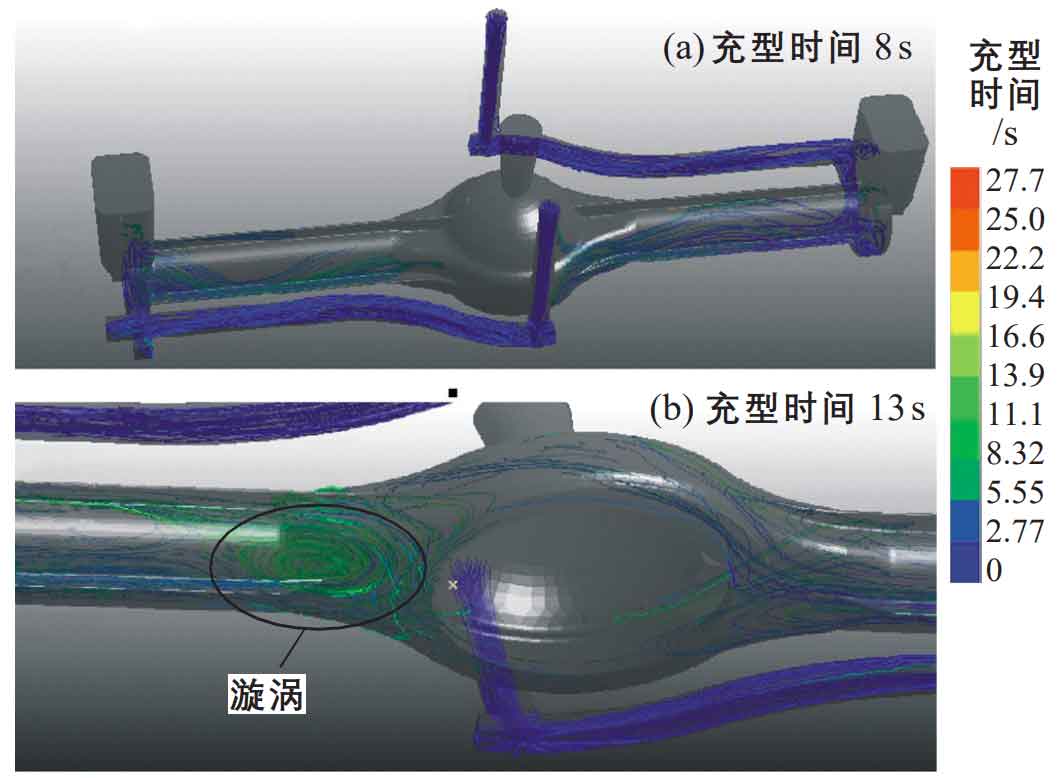

Fig. 2 is the particle tracking diagram of the casting of the rear axle of the excavator. It can be seen from the diagram that the liquid metal appears turbulence when pouring to 8s; When pouring to 13s, the liquid metal whirled in the middle of the rear axle casting of the excavator and lasted for 5S. From the whole filling process, the casting of the rear axle of the excavator is gradually stable after filling for 15s.

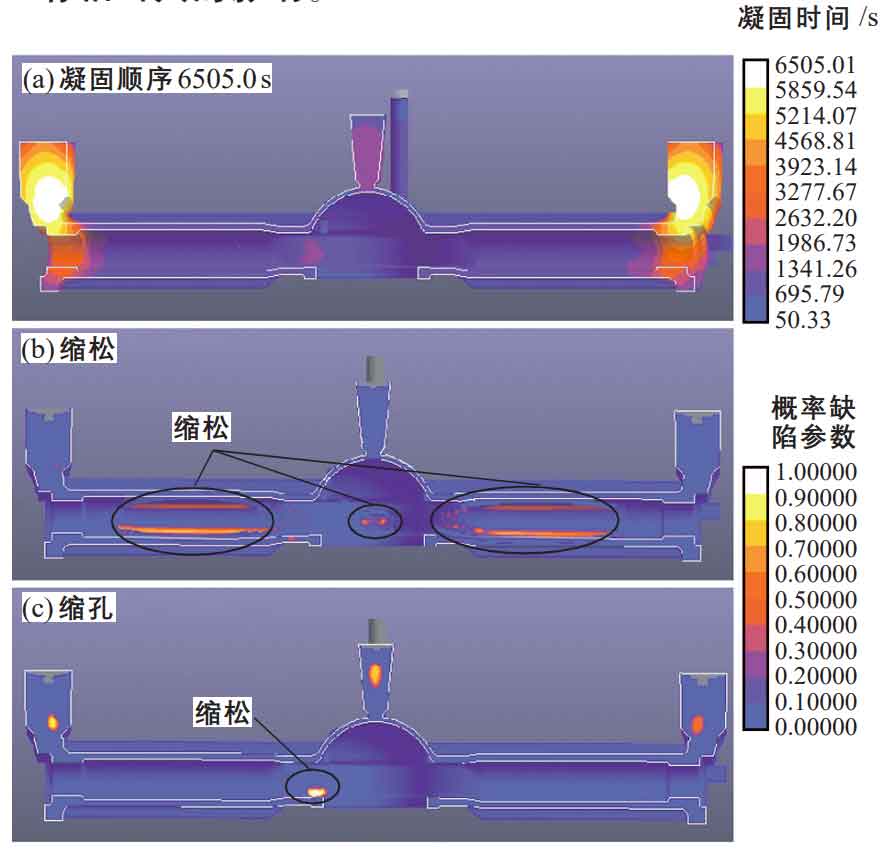

2. Analysis on solidification process of excavator rear axle casting

The solidification sequence, shrinkage porosity and shrinkage cavity distribution are analyzed in AnyCasting, as shown in Figure 3. From the solidification sequence distribution diagram in Figure 3 (a), it can be observed that the two ends of the excavator rear axle casting are located below the riser, and the solidification is late. The last solidified part of the excavator rear axle casting will be close to the two ends of the excavator rear axle casting, which is prone to shrinkage. From the analysis of shrinkage porosity and shrinkage cavity distribution in Fig. 3 (b) and (c), it can be seen that there are long strip shrinkage porosity defects on both sides of the excavator rear axle casting and shrinkage cavity defects in the middle of the excavator rear axle casting. These defects have a considerable impact on the quality of the excavator rear axle casting.