1. Meshing of process modeling

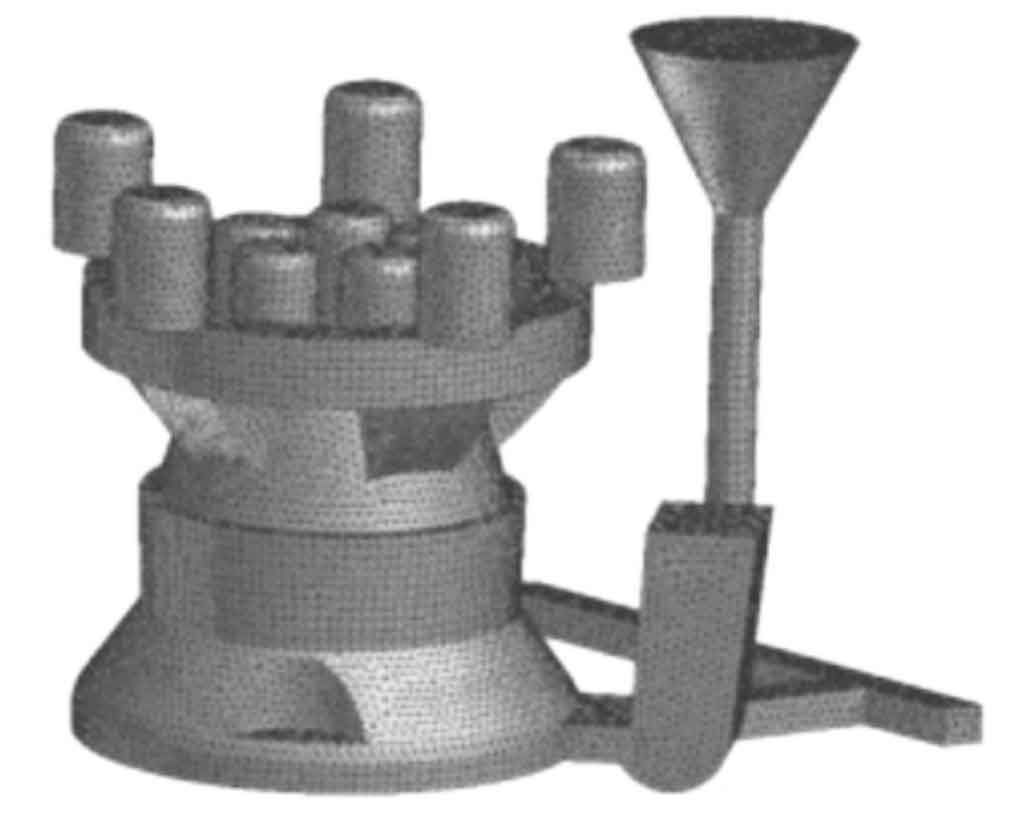

Using 3D modeling software creo2 0 carry out three-dimensional solid casting process modeling for castings. When the casting is meshed with the division module of ProCAST software, the maximum side length of the surface triangle of the model grid element is 7 mm, so the number of tetrahedral grids is 216326 and the number of nodes is 25470, as shown in Figure 1.

2. Setting material thermophysical parameters

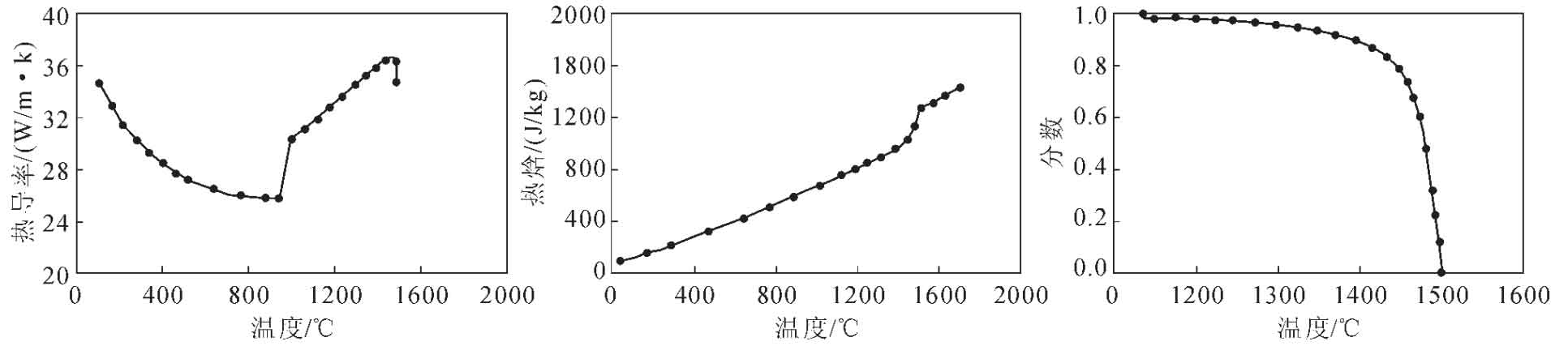

ZHY casting professionally tested the thermophysical properties of the materials used in the process to ensure the reliability of the numerical simulation calculation and analysis results. The test results are shown in Figure 2.

The density of the material is 7.8 g / cm3, the solidus temperature is 1446 ℃, and the liquidus temperature is 1503 ℃.

3. Setting initial and boundary conditions

According to the actual production process, the pouring temperature is 1560 ℃, the pouring speed is 16 kg / s, and the initial ambient temperature is 25 ℃.