Combined with the actual solidification process of sand castings, the three-dimensional model is established through UG, and ProCAST is used to simulate the solidification and cooling process of sand castings, in which the interface heat transfer coefficient calculated by the inverse problem is used for simulation: the interface heat transfer coefficient varying with the temperature of sand castings is obtained by the inverse calculation program. Then, the simulated temperature field results of sand castings are compared with the measured temperature field data of sand castings to verify the reliability and accuracy of the inverse calculation of interface heat transfer coefficient in the simulation.

ProCAST casting simulation software is selected for simulation verification. It discretizes the element of the obtained geometry based on the finite element method, and iteratively solves the discretized grid in time through the powerful mathematical model of the software itself.

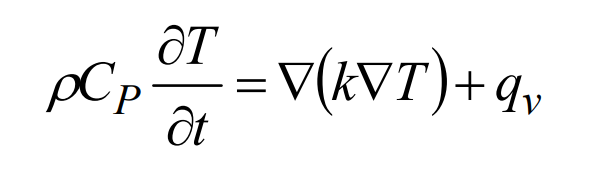

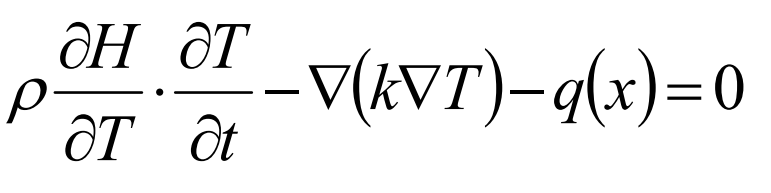

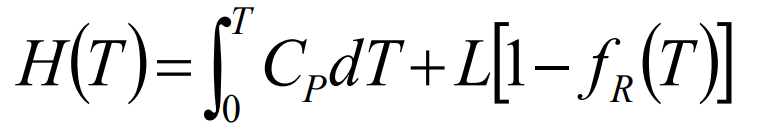

ProCAST numerical simulation software can accurately calculate the filling and solidification process of sand castings, and present the simulation results through a visual man-machine interface. Its mathematical model mainly includes energy equation, continuity equation and momentum equation. The energy equation includes transient linear equation and transient nonlinear equation, which are respectively as follows:

Where, ρ Is density; CP is the specific heat capacity; T is the temperature of the node; T is the time.

K is the steady-state thermal conductivity; QV is volume heat source.

Where, ρ Is density.

Where, l is latent heat; Is the solid rate.

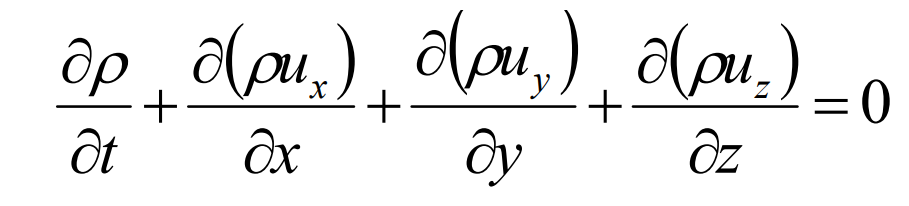

The continuity equation is:

Where UX, uy and UZ are the velocity of the unit in the X, y and Z directions respectively; x. Y and Z are the unit vectors of the element in two directions respectively.

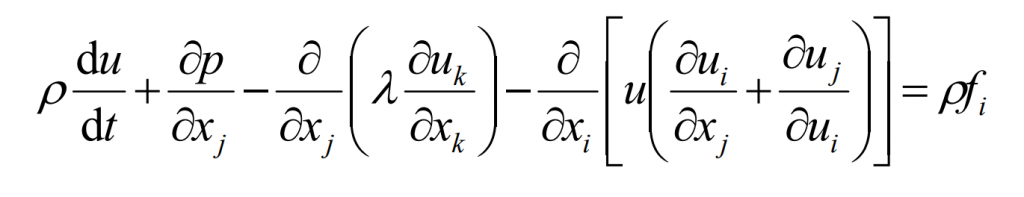

The momentum equation is:

Where, P is the pressure; FI is the gravitational acceleration of the unit; UI, UJ and UK are the velocity vectors of the unit in the I, J and K directions respectively.

ProCAST can accurately simulate the filling and solidification process of sand castings through these powerful mathematical models and network division ability when the initial conditions and boundary conditions are known.