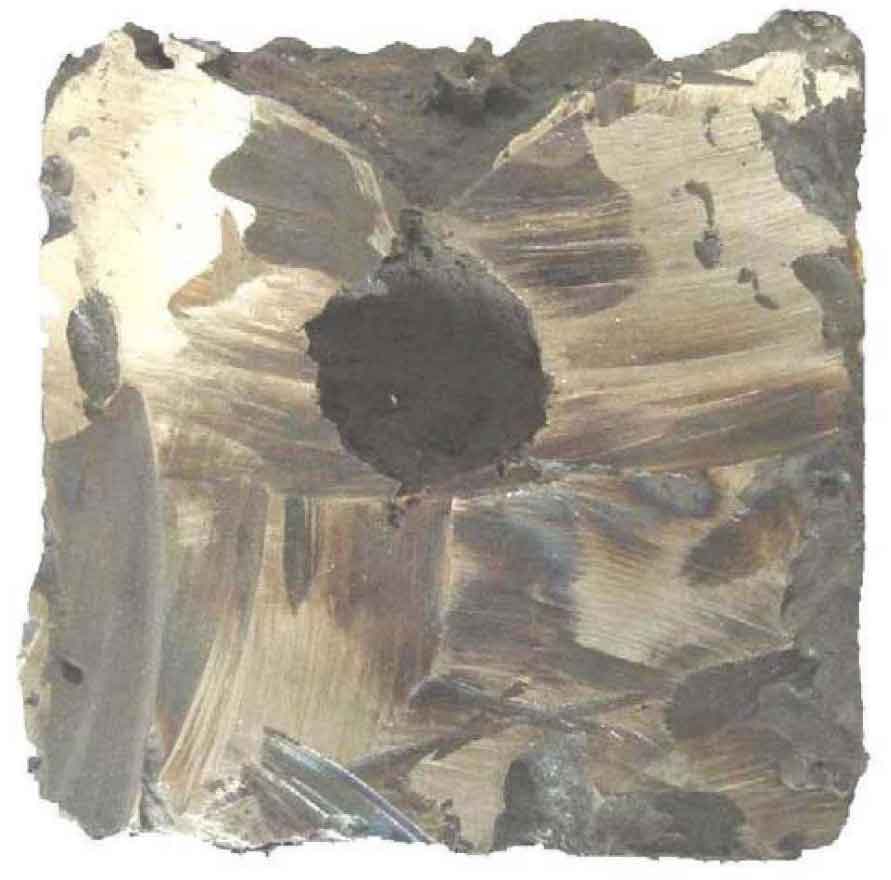

This steel casting is also an actual pouring example to test the simulation accuracy of the software. The shape of the steel casting is φ one hundred × The cylinder of H100 is made of ZGMn13, and the test pouring conditions are normal production workshop. The size, location and shape of shrinkage defects generated after actual dissection of steel castings are shown in Figure 1.

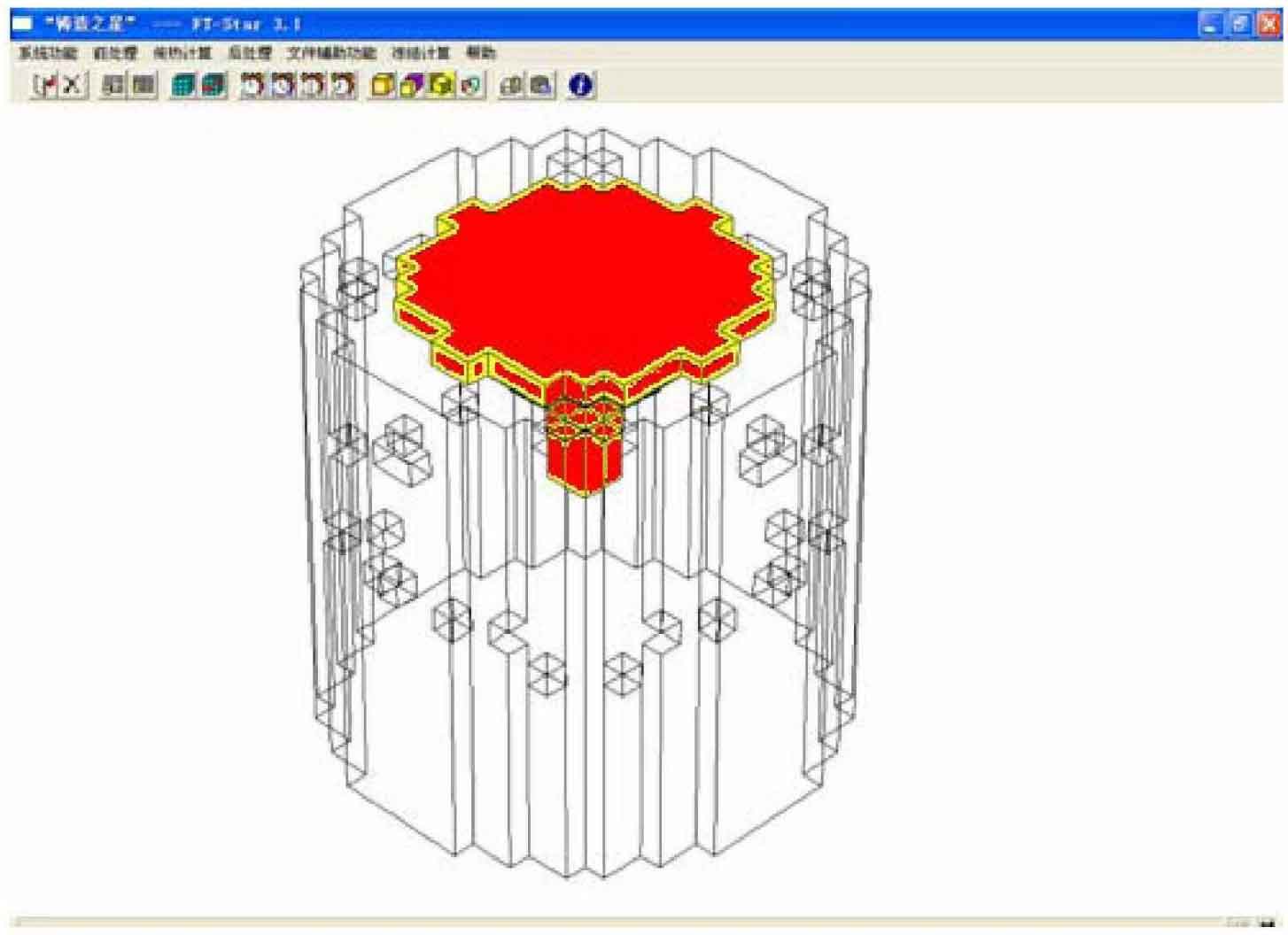

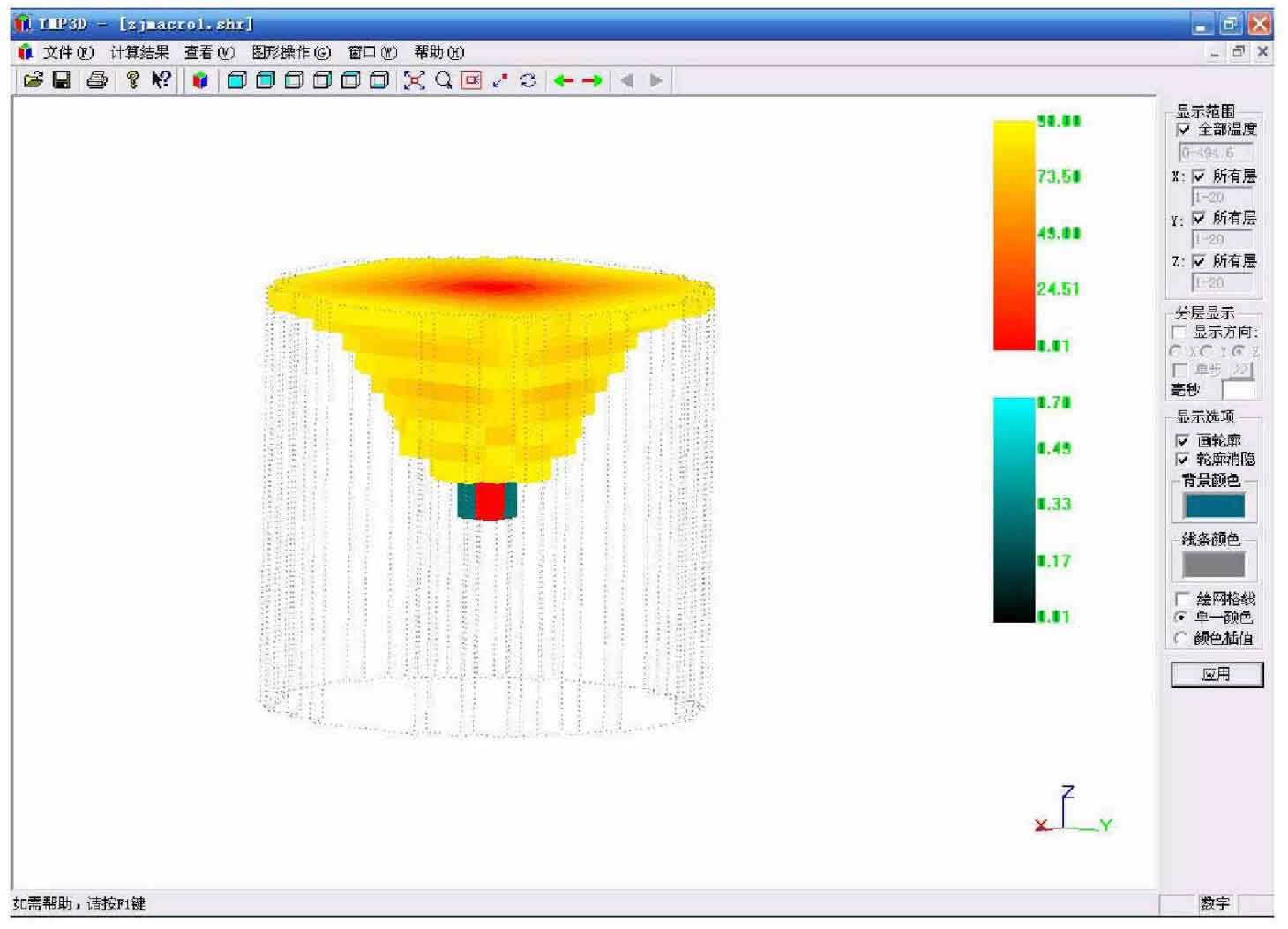

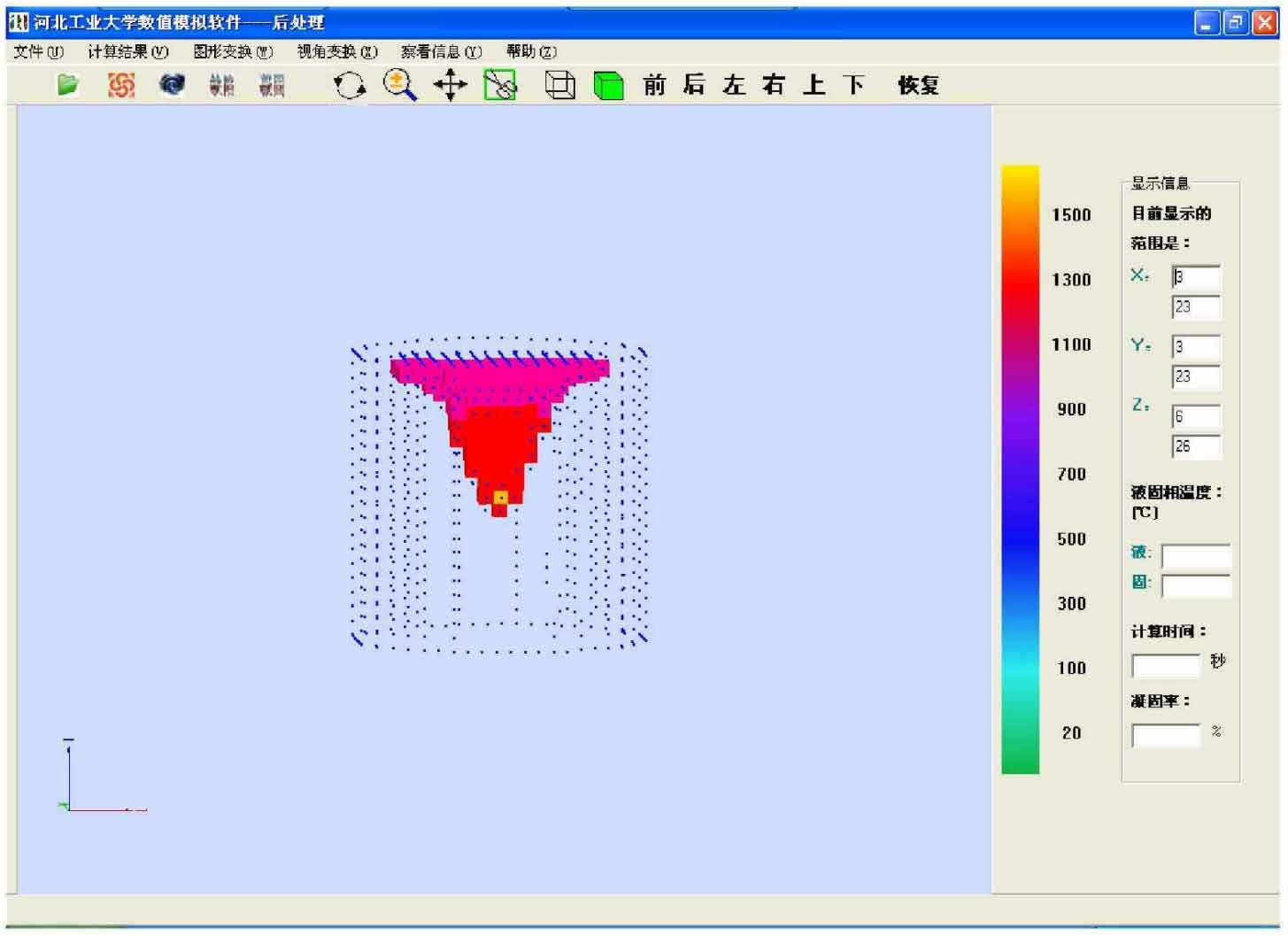

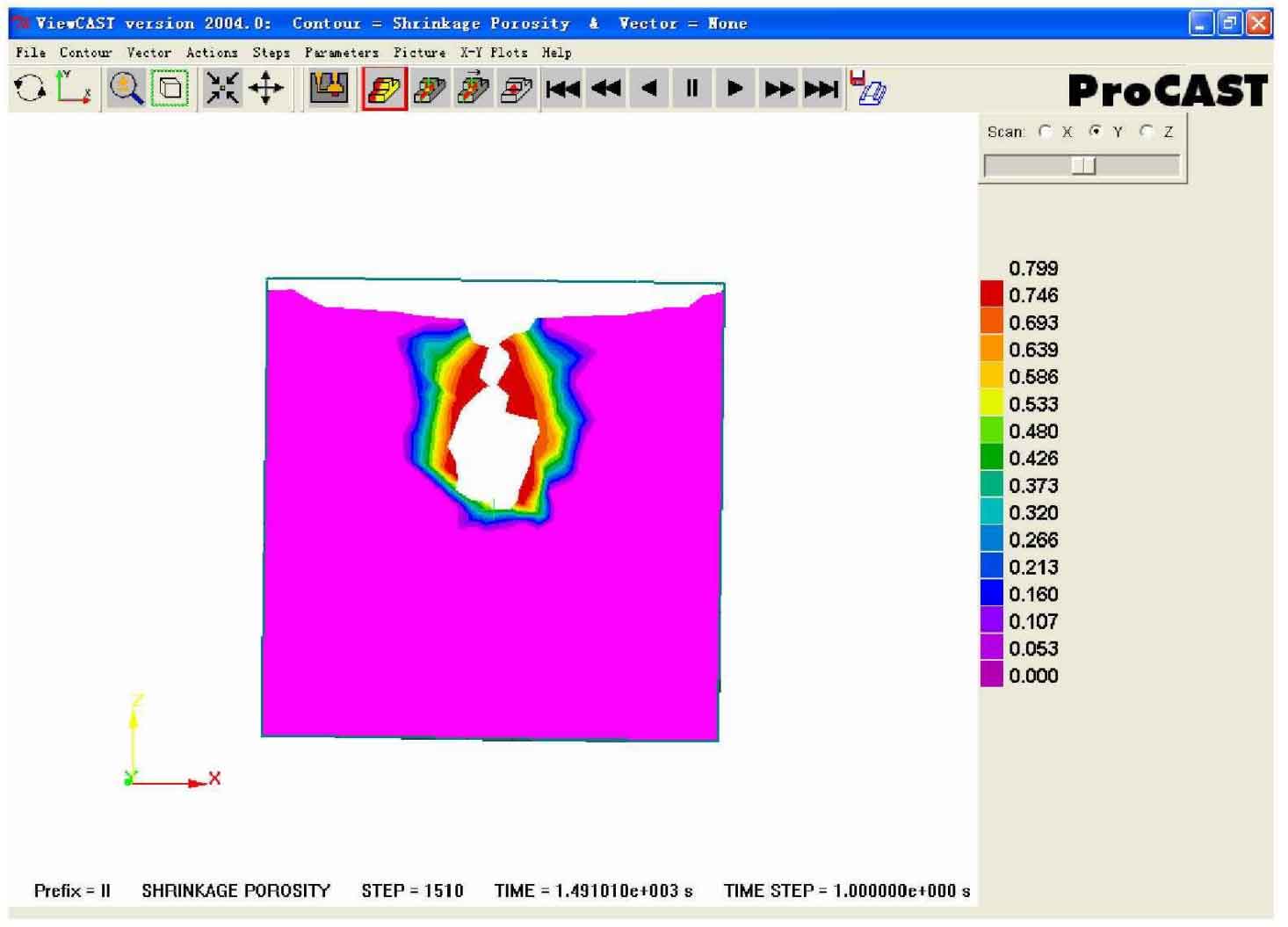

FT-Star of Tsinghua University and CASTsoft of Zhongbei University in China, ProCAST software of the United States and this software are used to simulate and predict this simple steel casting. The simulation results are shown in Figure 2-5:

From the simulation analysis of steel castings by the above three examples, in terms of defect simulation and prediction, whether from the perspective of actual production of steel castings or commercial numerical simulation software, in the solidification calculation of steel castings and other general alloys, the prediction of shrinkage porosity, shrinkage cavity and other defects has reached a very accurate level, which fully reaches the simulation and prediction accuracy of domestic software, but there is still a certain gap compared with world-famous software.