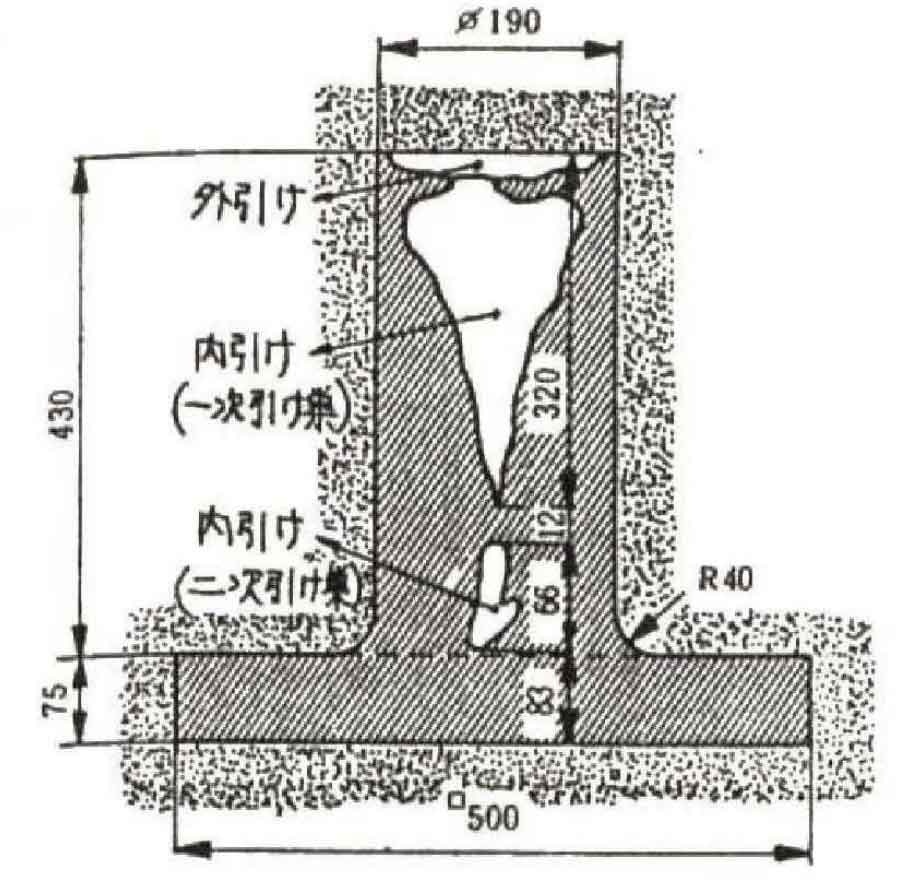

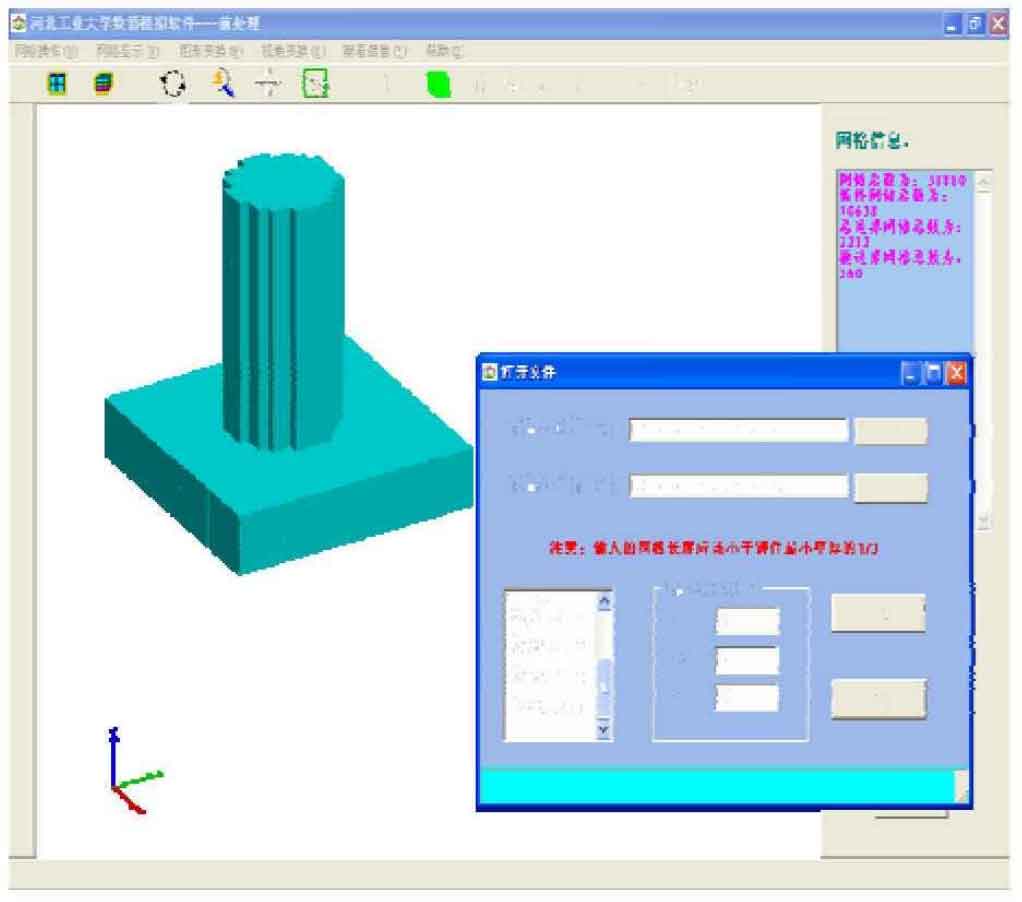

This flat casting was used in the riser verification experiment of secondary shrinkage formation carried out by Saburo Lintian in the early 1940s. This is a classic example of actual pouring and anatomical analysis. Many existing solidification simulation software are used as examples to test the prediction accuracy of the software. The actual dissected plate casting and its size are shown in Figure 1, the blank is the shrinkage cavity, and its three-dimensional shape is shown in Figure 2 after grid division.

Carry out UG three-dimensional solid modeling for this flat casting and mesh generation. The mesh generation and result display are shown in Figure 2, in which the size of the mesh is 20 × twenty × 20 cubic mm, the total number of units including mold after splitting is 38880.

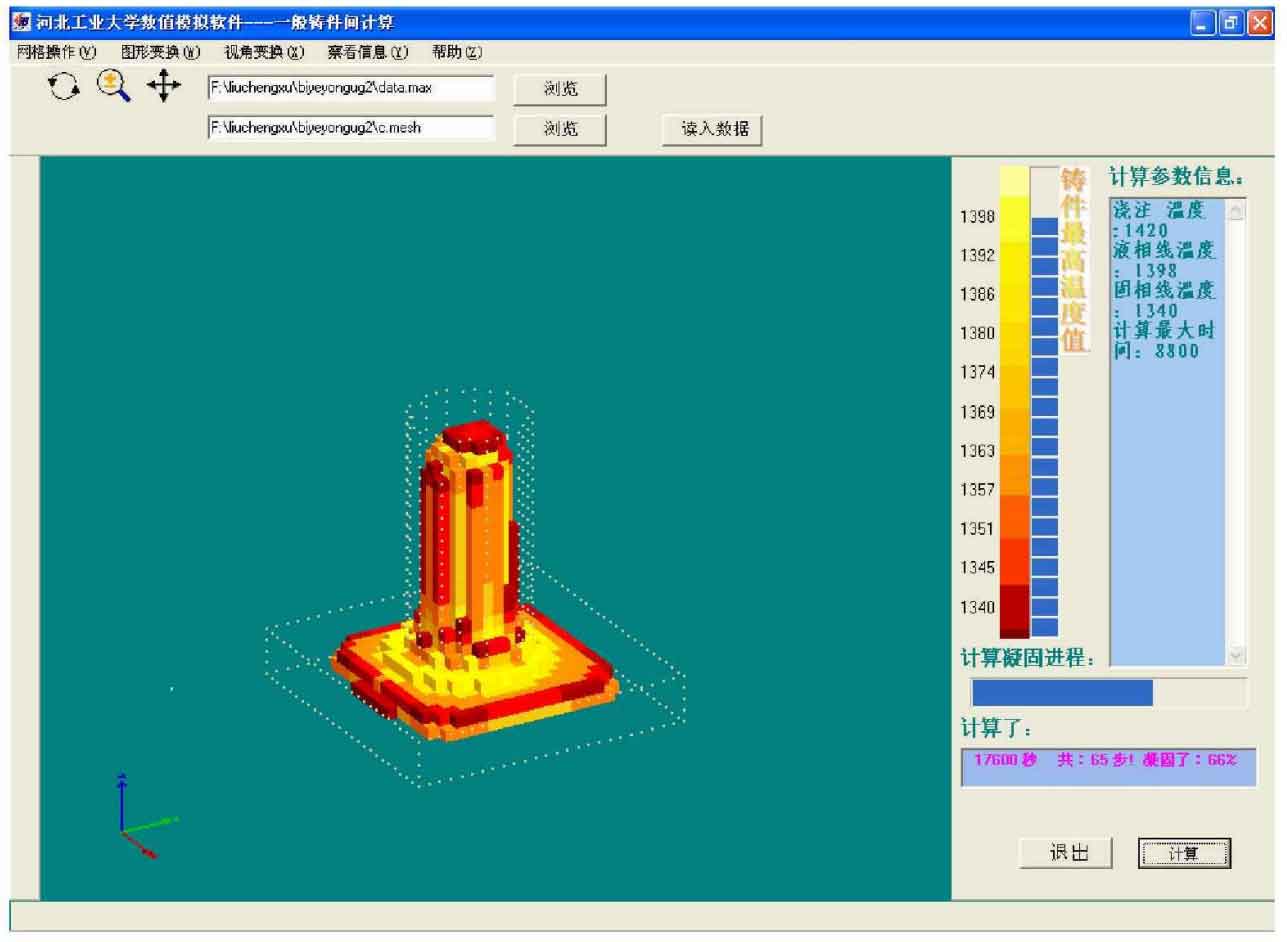

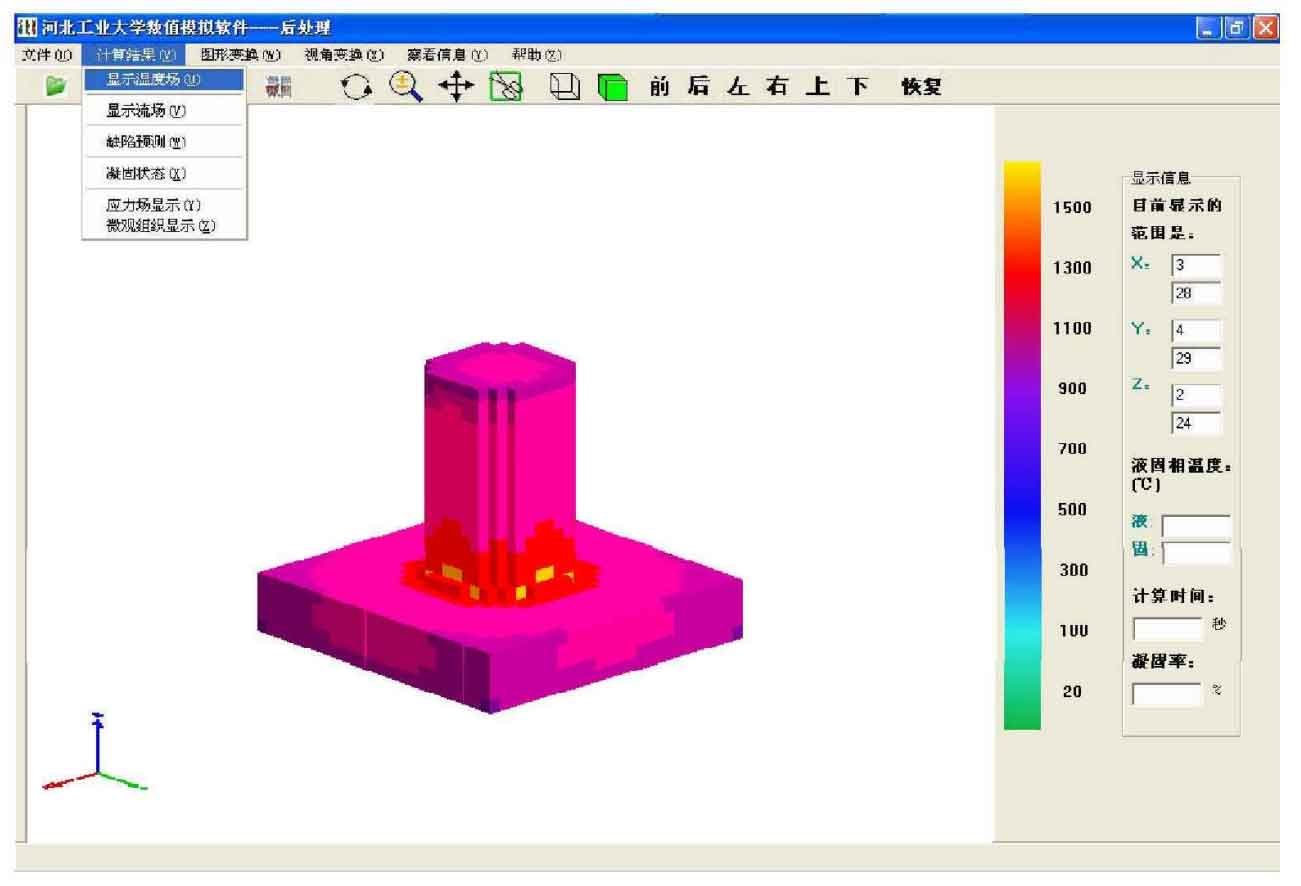

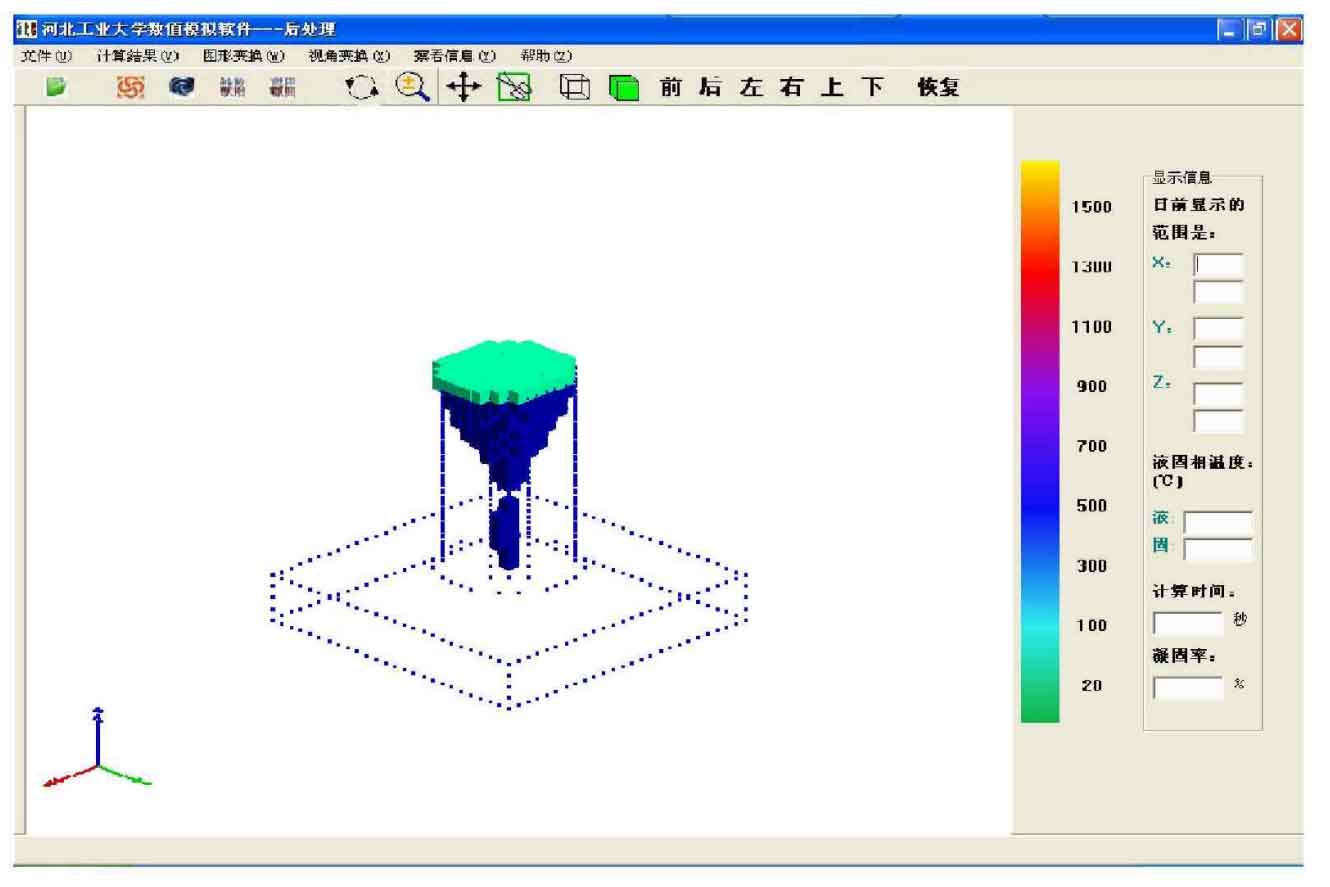

According to the software written by ourselves, the flat casting was simulated, and the shrinkage defects were predicted. As shown in Figure 3, the solidification dynamic display diagram of the calculation process shows the solidification advancement process; Figure 4 shows the post-processing temperature field display, which shows the temperature field distribution at a certain time in the calculation process, and the display result is based on the calculation file saved in the calculation process.

Figure 5 is the display diagram of simulated final shrinkage defects. From the calculation results, it can be seen that the predicted primary and secondary shrinkage defects are very close to the primary and secondary shrinkage defects in the actual flat casting. This also confirms the accuracy of the simulation of this program.