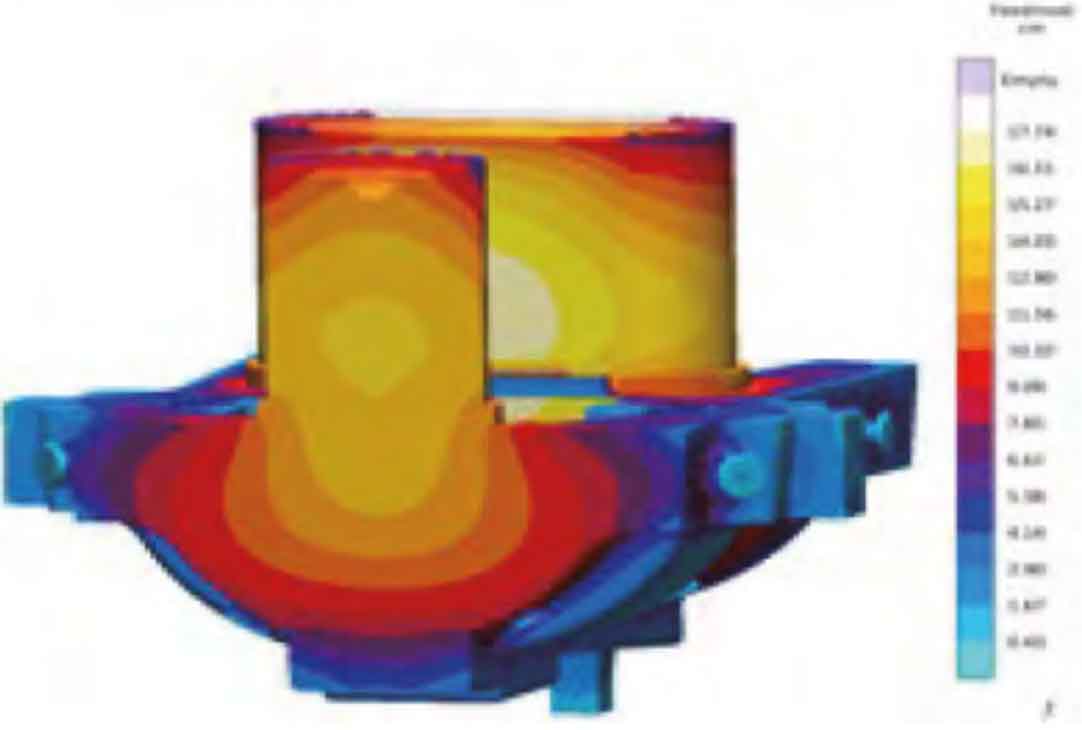

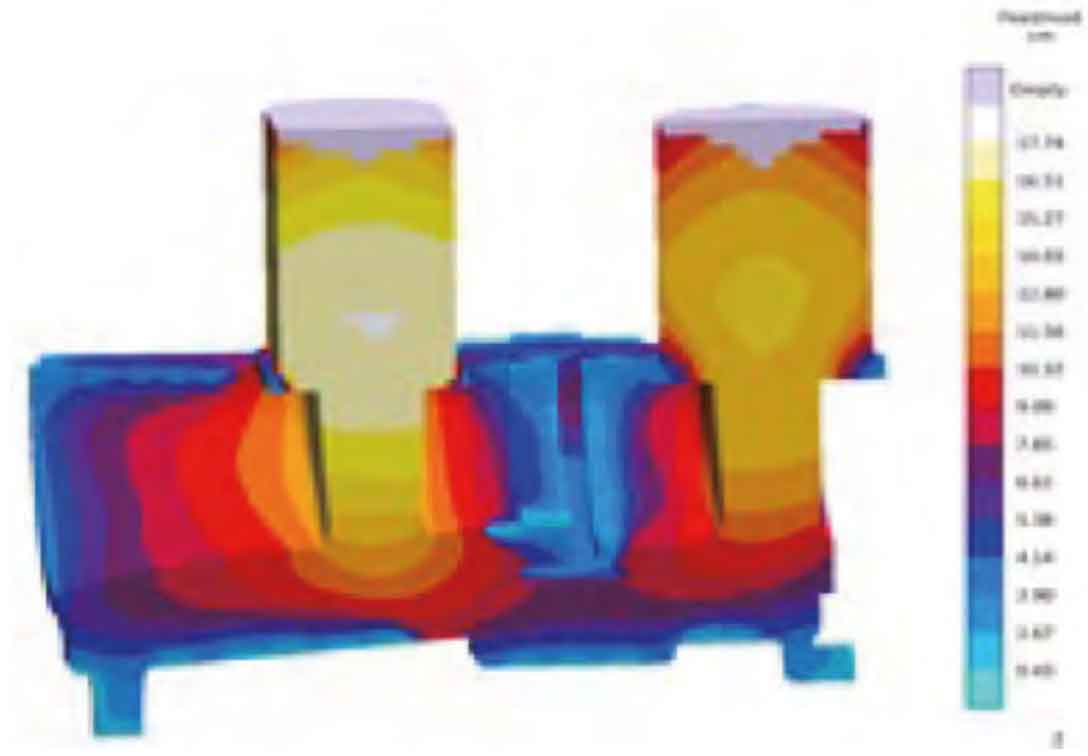

CAE simulation of casting process can increase design functions, reduce design costs, and shorten design cycles; And continuously optimize the design to find the best process design scheme for the product, reducing material consumption or trial production costs. The advanced computer simulation software MAGMA was used to simulate and analyze the solidification process of molten steel and optimize the casting process design. The simulation structure shows that the steel casting body has no tendency of shrinkage and porosity, and the modulus meets the requirements for sequential solidification of the steel casting and final solidification of the riser. Both the circumferential and axial directions meet the requirements for sequential solidification, as shown in Figure 1 and Figure 2. The riser and subsidy design is reasonable and can meet the quality requirements, as shown in Figure 3.

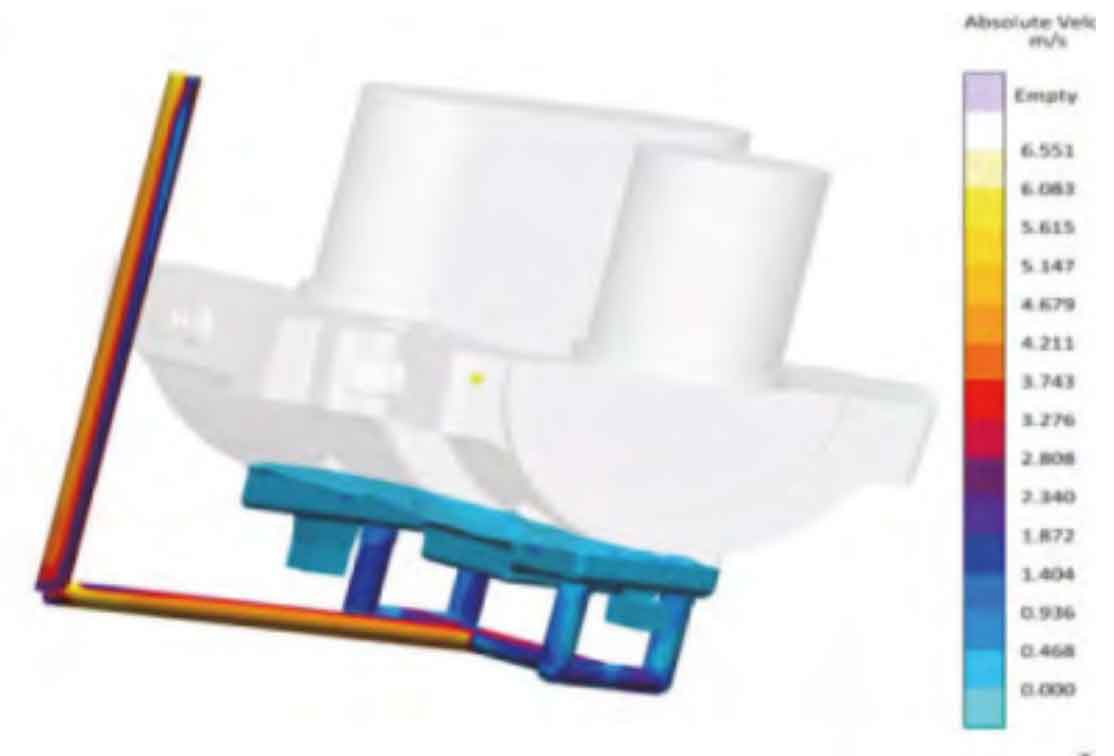

The simulation of the mold filling process of molten metal for steel castings shows that the liquid metal rises steadily and rapidly, without turbulence, splash, and entrainment. The gating system is reasonably designed, as shown in Figure 4.