Spheroidal graphite cast iron is a vital material in the manufacturing of heavy machinery due to its unique combination of strength, ductility, and wear resistance. The ability to balance these properties makes spheroidal graphite cast iron an ideal choice for various industrial applications, from construction equipment to agricultural machinery. This article explores how spheroidal graphite cast iron achieves this balance, highlighting the critical factors, alloying elements, and production techniques that contribute to its performance. Comprehensive tables and lists are included to provide a detailed understanding.

Introduction

Heavy machinery used in industrial applications requires materials that can withstand extreme stresses and harsh operating conditions while maintaining flexibility to absorb impacts and avoid brittle failure. spheroidal graphite cast iron, with its spheroidal graphite inclusions, offers an optimal combination of high strength and flexibility, making it suitable for such demanding environments. This article delves into the properties of spheroidal graphite cast iron, the role of alloying elements, and the production processes that ensure its performance in heavy machinery.

Properties of Spheroidal Graphite Cast Iron

- Strength: High tensile and yield strength, allowing it to bear heavy loads.

- Ductility: The spheroidal shape of graphite nodules provides superior ductility compared to gray cast iron.

- Wear Resistance: Excellent resistance to abrasion and wear, extending the lifespan of components.

- Impact Resistance: High toughness, enabling it to absorb shocks and impacts without cracking.

- Machinability: Good machinability, making it easier to fabricate complex components.

Table: Key Properties of Spheroidal Graphite Cast Iron

| Property | Description | Industrial Relevance |

|---|---|---|

| Strength | High tensile and yield strength | Supports heavy loads, ideal for structural components |

| Ductility | Superior to gray cast iron due to spheroidal graphite | Reduces risk of brittle failure, absorbs impacts |

| Wear Resistance | Excellent resistance to abrasion and wear | Enhances durability, reduces maintenance needs |

| Impact Resistance | High toughness | Absorbs shocks and impacts, suitable for dynamic environments |

| Machinability | Good machinability | Facilitates fabrication of complex components |

Role of Alloying Elements in Spheroidal Graphite Cast Iron

- Carbon (C): Essential for graphite formation. Optimal levels ensure a balance between strength and ductility.

- Silicon (Si): Promotes graphite formation and enhances ductility. Helps stabilize the ferritic matrix.

- Magnesium (Mg): Converts flake graphite to spheroidal form, enhancing strength and ductility.

- Nickel (Ni): Increases toughness and corrosion resistance, beneficial for components exposed to harsh environments.

- Copper (Cu): Enhances tensile strength and hardness, important for wear-resistant applications.

- Manganese (Mn): Improves strength and hardness but must be controlled to avoid excessive carbide formation.

- Chromium (Cr): Increases wear resistance and hardness, suitable for components subject to high friction.

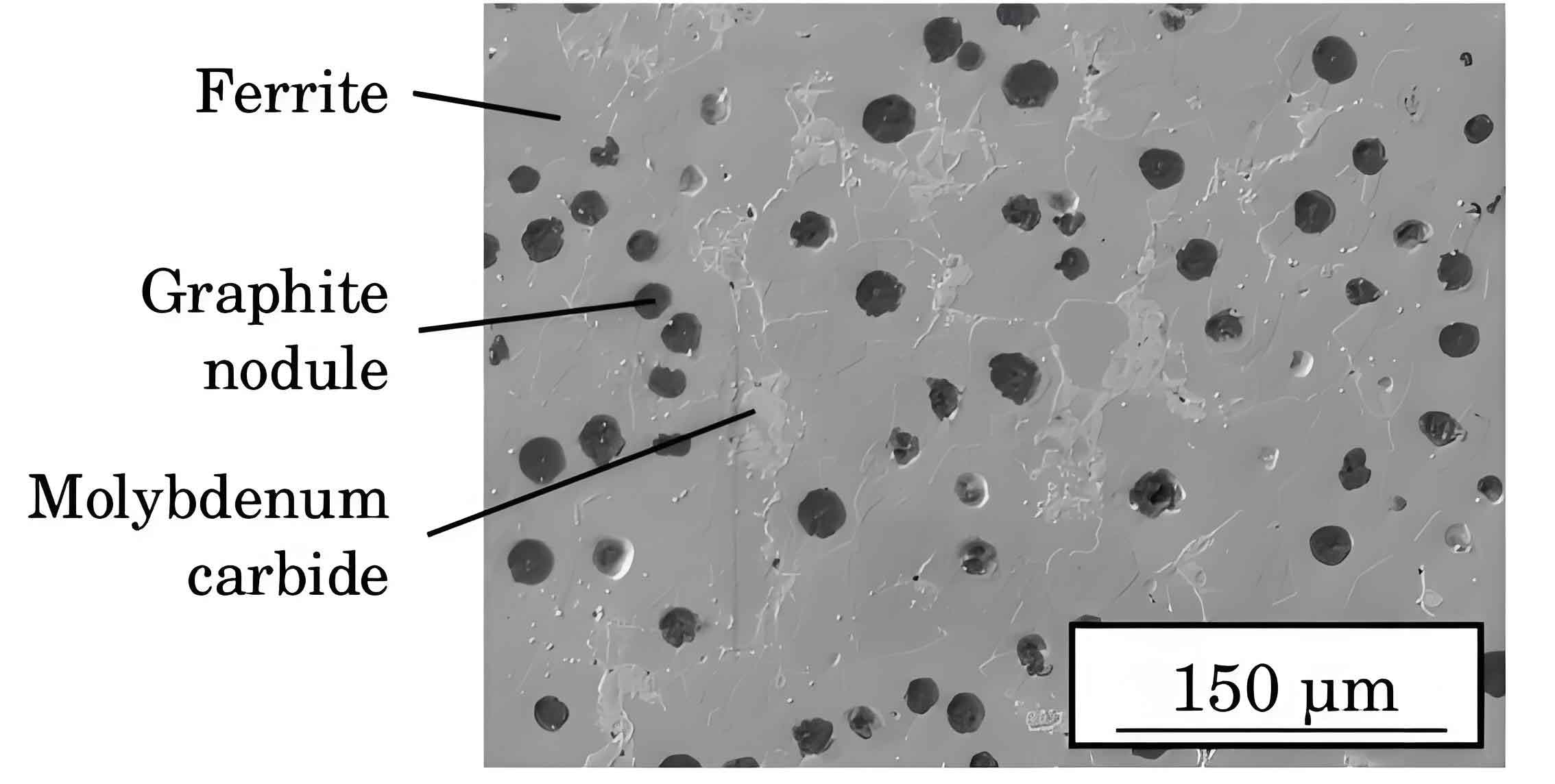

- Molybdenum (Mo): Enhances high-temperature strength and resistance to thermal fatigue, ideal for heat-exposed parts.

- Tin (Sn): Promotes pearlitic matrix, increasing strength and hardness.

- Rare Earth Elements (Ce, La): Improve nodule formation and consistency, reducing sensitivity to impurities.

Table: Alloying Elements and Their Effects

| Element | Role | Effect on Spheroidal Graphite Cast Iron |

|---|---|---|

| Carbon (C) | Graphite formation | Balances strength and ductility |

| Silicon (Si) | Promotes graphite, enhances ductility | Stabilizes ferritic matrix, improves ductility |

| Magnesium (Mg) | Converts flake to spheroidal graphite | Enhances strength and ductility |

| Nickel (Ni) | Increases toughness, corrosion resistance | Improves toughness and corrosion resistance |

| Copper (Cu) | Enhances strength and hardness | Increases tensile strength and hardness |

| Manganese (Mn) | Improves strength and hardness | Must be controlled to avoid excessive carbide formation |

| Chromium (Cr) | Increases wear resistance, hardness | Suitable for high friction applications |

| Molybdenum (Mo) | Enhances high-temperature strength | Ideal for components exposed to heat |

| Tin (Sn) | Promotes pearlitic matrix | Increases strength and hardness |

| Rare Earth Elements (Ce, La) | Improve nodule formation, reduce impurities sensitivity | Enhance consistency and reduce defect rates |

Balancing Strength and Flexibility

- Microstructure Control:

- Graphite Nodule Formation: Controlled by carbon and magnesium content.

- Matrix Composition: Silicon and nickel promote a ferritic matrix, enhancing ductility. Copper and tin stabilize pearlite, increasing strength.

- Heat Treatment:

- Annealing: Reduces internal stresses, improves ductility.

- Normalizing: Refines microstructure, enhances strength and toughness.

- Austempering: Produces a bainitic structure, combining high strength and toughness.

- Casting Techniques:

- Inoculation: Adds elements to molten iron to control graphite nodule formation.

- Cooling Rate Control: Slow cooling promotes ferritic matrix, fast cooling promotes pearlitic matrix.

List: Techniques to Balance Strength and Flexibility

- Microstructure Control:

- Graphite nodule formation (carbon, magnesium)

- Matrix composition (silicon, nickel, copper, tin)

- Heat Treatment:

- Annealing

- Normalizing

- Austempering

- Casting Techniques:

- Inoculation

- Cooling rate control

Industrial Applications of Spheroidal Graphite Cast Iron in Heavy Machinery

- Construction Equipment:

- Excavators: High-strength, wear-resistant components for digging and loading.

- Bulldozers: Durable parts that withstand heavy loads and impacts.

- Agricultural Machinery:

- Tractors: Robust components that endure rough terrains and heavy use.

- Harvesters: Wear-resistant parts for cutting and processing crops.

- Mining Equipment:

- Drills and Crushers: High-impact resistant components for breaking rocks.

- Conveyors: Durable, wear-resistant parts for material handling.

- Industrial Machinery:

- Presses and Molds: High-strength, tough components for manufacturing processes.

- Pumps and Valves: Corrosion-resistant parts for fluid handling in harsh environments.

Table: Industrial Applications of Spheroidal Graphite Cast Iron

| Industry | Equipment | Spheroidal Graphite Cast Iron Component Properties |

|---|---|---|

| Construction | Excavators, Bulldozers | High strength, wear resistance, impact resistance |

| Agriculture | Tractors, Harvesters | Robustness, wear resistance, durability |

| Mining | Drills, Crushers, Conveyors | Impact resistance, wear resistance, high strength |

| Industrial Manufacturing | Presses, Molds, Pumps, Valves | High strength, toughness, corrosion resistance |

Future Trends in Spheroidal Graphite Cast Iron for Heavy Machinery

- Advanced Alloy Development:

- Customized Alloys: Development of alloys tailored for specific applications to enhance performance.

- Nanotechnology: Incorporation of nanomaterials to improve microstructure and mechanical properties.

- Sustainable Production:

- Recycling: Increased use of recycled materials to reduce environmental impact.

- Energy Efficiency: Implementation of energy-efficient production processes.

- Smart Manufacturing:

- IoT and AI: Integration of IoT and AI for real-time monitoring and optimization of production processes.

- Predictive Maintenance: Use of predictive analytics to foresee and prevent equipment failures.

- Research and Development:

- Collaborative Efforts: Partnerships between industry and academia to drive innovation.

- Government Initiatives: Leveraging government support for advanced research in spheroidal graphite cast iron applications.

List: Future Trends in Spheroidal Graphite Cast Iron for Heavy Machinery

- Advanced Alloy Development:

- Customized alloys

- Nanotechnology

- Sustainable Production:

- Recycling

- Energy efficiency

- Smart Manufacturing:

- IoT and AI integration

- Predictive maintenance

- Research and Development:

- Collaborative efforts

- Government initiatives

Conclusion

Spheroidal graphite cast iron plays a crucial role in the heavy machinery industry by providing an optimal balance of strength and flexibility. Through careful control of alloying elements, microstructure, and production techniques, spheroidal graphite cast iron components can meet the demanding requirements of various industrial applications. As advancements in alloy development, sustainable production, and smart manufacturing continue to evolve, spheroidal graphite cast iron will remain a cornerstone material, offering enhanced performance and reliability for heavy machinery in diverse industries.