Adjust carbon equivalent and silicon carbon ratio. In the solidification of gray cast iron, the carbon equivalent directly affects the alloy solidification temperature and solidification temperature range, the primary phase precipitated first, the type of eutectic phase and the phase composition of gray cast iron, so as to determine the microstructure, mechanical properties, physical properties, service properties and process properties of gray cast iron. Therefore, the carbon equivalent should be determined according to the casting section size, required mechanical properties, process properties and service properties. The carbon equivalent of gray cast iron used for structural parts is generally between 3.5% – 4.2%, and the carbon equivalent (CE) of heavy machine tool base parts is between 3.5% – 4.9%. The increase of carbon equivalent will lead to the decrease of mechanical properties of gray cast iron, that is, the decrease of hardness and tensile strength.

The relationship between tensile strength and carbon equivalent of gray cast iron is shown in Figure 1. When carbon equivalent is less than or equal to 4.05%, the tensile strength is greater than or equal to 250Mpa. However, the selection of carbon equivalent should be appropriate. Low carbon equivalent will improve the tensile strength, but at the same time, it will deteriorate the casting performance, deteriorate the cutting performance and improve the section sensitivity of gray cast iron castings; When the carbon equivalent is too high, the graphite will be thick, and the tensile strength and hardness will decrease. At the same time, the determination of carbon equivalent should also be related to carbon Relative content of silicon (i.e. silicon carbon ratio). Under certain carbon equivalent conditions, the strength can be improved by adjusting the silicon carbon ratio. As shown in Figure 2, there is an appropriate silicon carbon ratio for each carbon equivalent. It can be seen from Figure 2 that when CE = 3.6% – 3.8% and the silicon carbon ratio is 0.5-0.75, the tensile strength of gray cast iron increases with the increase of silicon carbon ratio, but when the silicon carbon ratio is large At 0.75, the tensile strength of gray cast iron decreases with the increase of silicon carbon ratio; When CE > 3.8%, the effect of silicon carbon ratio on tensile strength is not obvious.

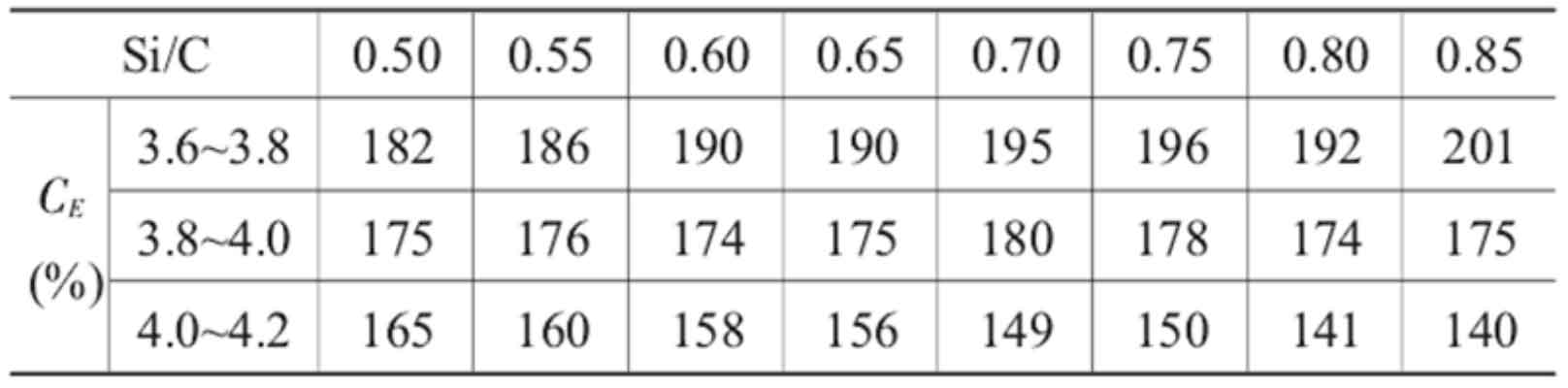

The table lists the values of hardness increasing with silicon carbon ratio in different carbon equivalent ranges. It can be seen that when the carbon equivalent is between 3.6% – 3.8%, the hardness increases with the increase of silicon carbon ratio. At this time, the amount of ferrite precipitation is less, the silicon carbon ratio increases, and the solid solution strengthening effect of silicon in gray iron castings increases, which improves the hardness; When the carbon equivalent is 4.0% – 4.2%, the hardness decreases with the increase of silicon carbon ratio because of more ferrite precipitation; When the carbon equivalent is between 3.8% – 4.0%, the hardness value remains unchanged or slightly increases with the increase of silicon carbon ratio. High silicon carbon ratio is adopted in production, and the gray cast iron with high strength and appropriate hardness can be obtained by adjusting the carbon equivalent according to the needs, so as to greatly improve the mechanical properties of gray cast iron.