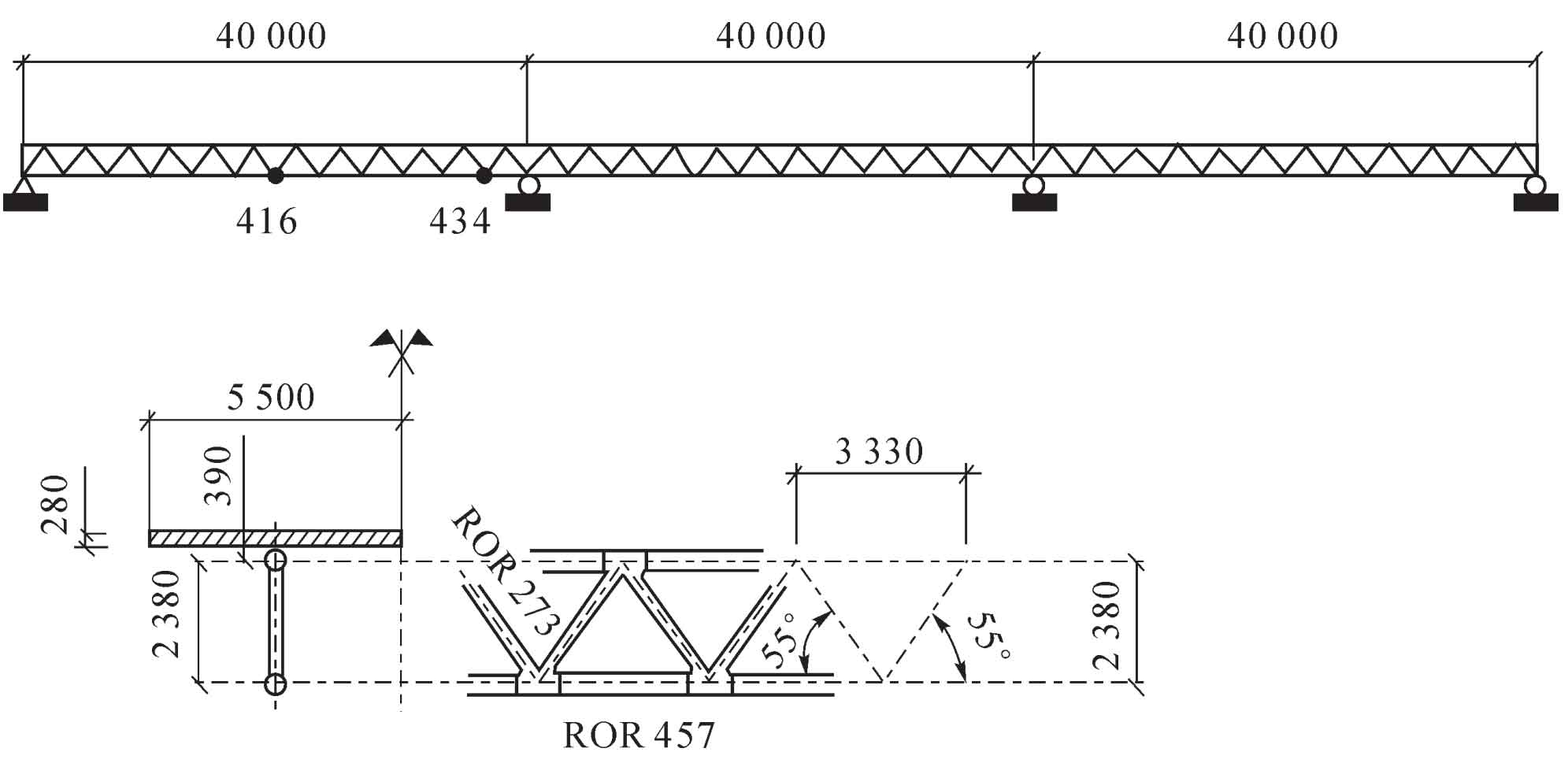

In order to effectively analyze the fatigue performance of cast steel joints in tubular truss bridge, a tubular truss bridge model with cast steel joints is designed, and the effects of different casting defect parameters on the fatigue performance of cast steel joints are studied through numerical simulation, so as to put forward corresponding suggestions for the evaluation of existing steel castings. Figure 1 shows the geometric and structural model of pipe truss bridge. The top of the pipe truss structure is 50A I-beam.

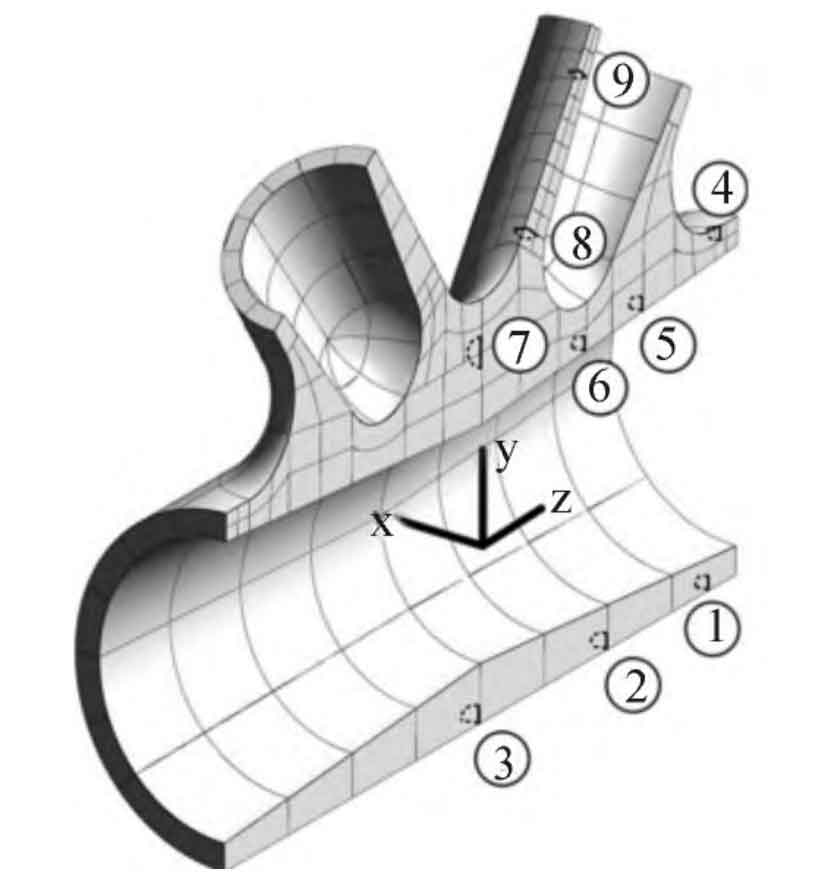

The cast steel joint used is K-type cast steel joint. Aiming at the randomness of casting defect location, many researchers analyzed the defect distribution of each location based on the analysis of casting node slice. The proposed 9 representative defect locations are suitable for the K-joint analysis task of truss bridge.

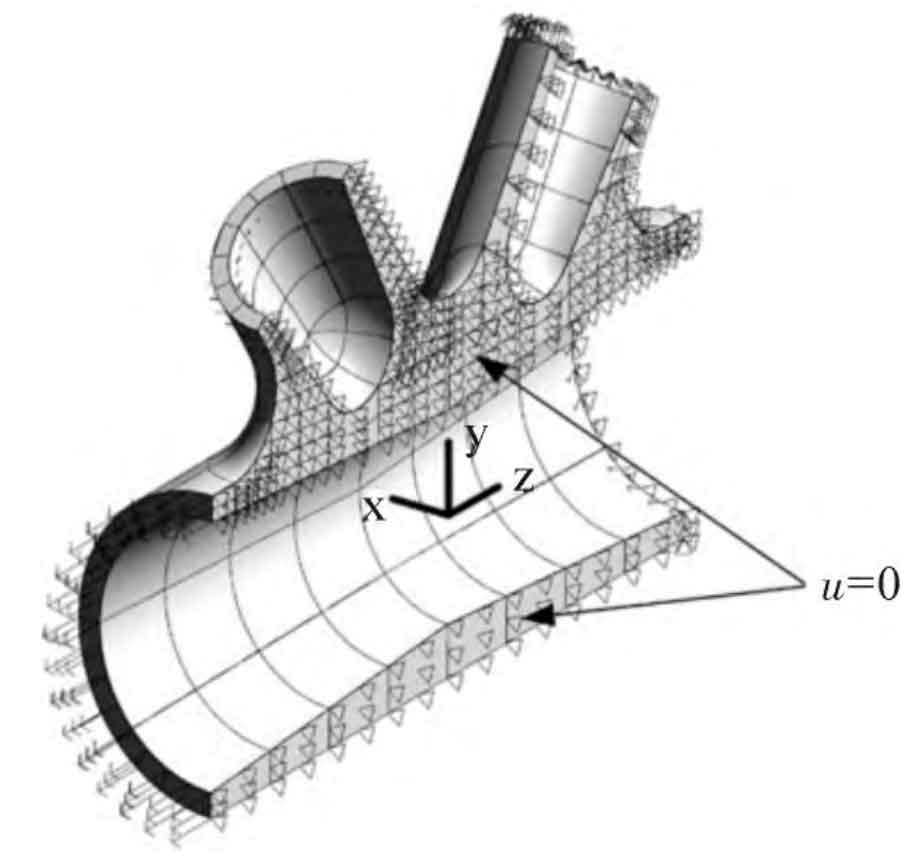

Figure 2 shows the location distribution of 9 casting defects used. It can be seen that the defect position ① ② ③ is distributed at the lower part of the main pipe, the defect position ④ is distributed at the upper part of the main pipe, the defect position ⑤⑥⑦ is distributed at the connecting part between the main pipe and the branch pipe, and the defect position ⑧⑨ is distributed inside the branch pipe. The commercial software BEASY is used to model the numerical boundary finite element of cast steel joints, as shown in Figure 3. The parameter u in Figure 3 represents the displacement field outside the pipe wall.