Mining excavators, commonly deployed in tunnel construction and underground mining operations, rely heavily on bucket teeth for efficient material excavation and loading. These critical components endure extreme operational stresses from constant rock-soil interactions, leading to premature wear, fractures, and bending failures. Such failures cause significant production downtime and economic losses, necessitating rigorous structural strength optimization through advanced simulation methodologies.

Finite Element Analysis (FEA) provides the theoretical foundation for evaluating bucket tooth performance under static and dynamic loads. The core governing equation for static structural response is:

$$ KU = F_1 + F_2 $$

where \( K \) represents the stiffness matrix, \( U \) the displacement vector, \( F_1 \) the external load vector, and \( F_2 \) the reaction force vector. The stress-strain relationship follows Hooke’s law:

$$ \sigma = E\epsilon $$

where \( \sigma \) denotes stress, \( E \) the elastic modulus, and \( \epsilon \) strain. These equations enable computational prediction of stress concentrations and deformation patterns in bucket teeth.

Finite Element Modeling Approach

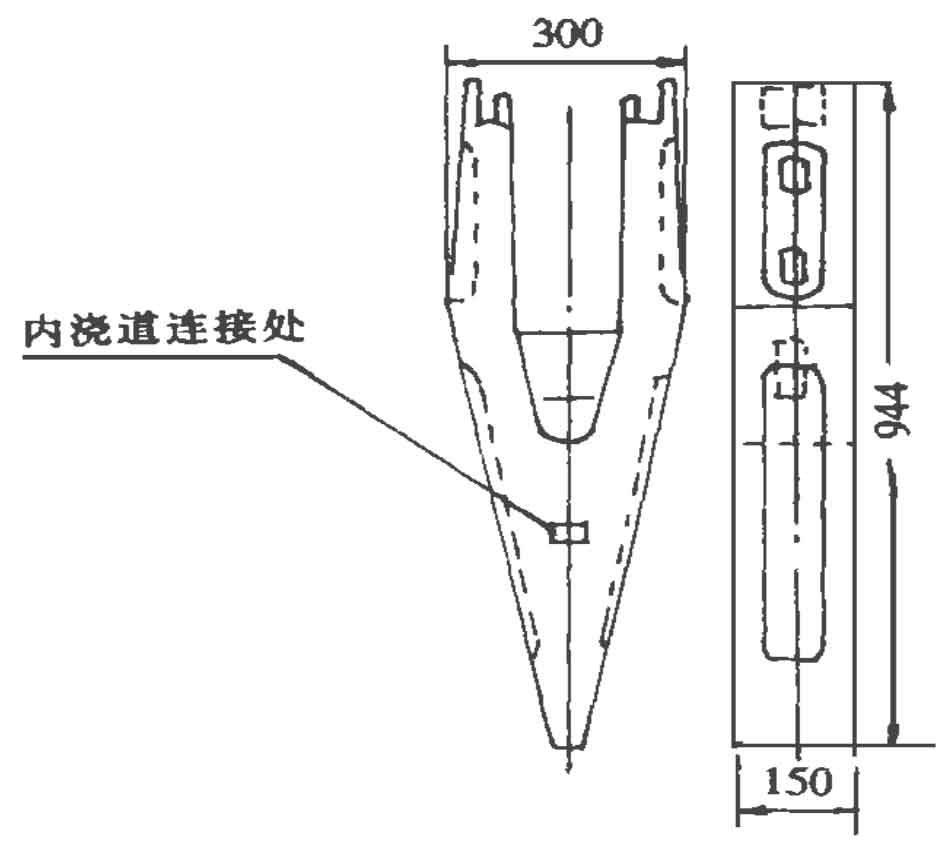

Three distinct bucket tooth geometries were modeled using C3D8 hexahedral elements:

- Type A: Symmetrical planar design (0mm concave radius)

- Type B: Asymmetrical design with moderate concave curvature (300mm radius)

- Type C: Asymmetrical design with pronounced concave curvature (600mm radius)

Boundary conditions simulated operational constraints:

- Fixed constraints applied to upper mounting surfaces

- Dynamic impact loads applied normal to cutting edges

- Material properties: High-manganese steel (Elastic modulus = 210 GPa, Poisson’s ratio = 0.3)

Simulation Results and Parametric Analysis

Stress distribution patterns varied significantly across bucket tooth configurations:

| Bucket Tooth Type | Max Stress Location | Max Displacement Location | Reaction Force Concentration |

|---|---|---|---|

| Type A (0mm) | Pin connection area | Cutting edge tip | Symmetric compression |

| Type B (300mm) | Concave surface midpoint | Concave-side tip | Pin connection area |

| Type C (600mm) | Distributed along curvature | Concave-side tip | Pin connection area |

Concave radius variations profoundly influenced mechanical responses:

| Concave Radius (mm) | Max Stress (MPa) | Stress Distribution Characteristic |

|---|---|---|

| 0 | 347 | Concentrated at pin joint |

| 100 | 412 | Moderate stress migration |

| 200 | 482 | Peak stress concentration |

| 300 | 453 | Redistribution initiation |

| 400 | 379 | Stabilized stress field |

| 500 | 375 | Uniform distribution |

| 600 | 372 | Uniform distribution |

| Concave Radius (mm) | Max Displacement (mm) | Max Reaction Force (kN) |

|---|---|---|

| 0 | 4.8 | 102 |

| 100 | 5.3 | 118 |

| 200 | 5.9 | 136 |

| 300 | 6.2 | 157 |

| 400 | 6.5 | 184 |

| 500 | 6.7 | 228 |

| 600 | 6.7 | 283 |

Key observations from parametric studies:

- Stress reduction of 23% observed in Type C bucket teeth compared to Type A

- Pin-joint stress concentrations decreased by 18-25% in asymmetrical designs

- Reaction forces increased exponentially beyond 300mm radius

- Displacement plateauing occurred at 400-600mm radius range

Structural Performance Optimization

Optimal bucket tooth design balances stress distribution and reaction forces through:

$$ \text{Structural Efficiency} = \frac{\sigma_{min}}{\delta_{max} \times R_{max}} $$

where \( \sigma_{min} \) is minimized peak stress, \( \delta_{max} \) controlled displacement, and \( R_{max} \) reaction force. Performance improvements include:

- Curvature-induced stress redistribution reduces local failure risks

- Asymmetrical designs decrease pin-joint stress by 18-25%

- Controlled deformation modes enhance energy absorption

Conclusion

Concave radius variation significantly alters bucket tooth structural behavior. Asymmetrical designs (Type B/C) demonstrate superior stress distribution compared to symmetrical configurations (Type A), particularly in reducing critical pin-joint stresses by 18-25%. The 200mm radius emerges as the stress concentration apex, while radii beyond 400mm yield stable stress fields. Reaction forces exhibit exponential growth past 300mm, necessitating balanced geometry selection. These findings enable optimized bucket tooth designs that enhance service life while minimizing maintenance frequency in harsh mining environments.