In the experiment, the molten iron of the same furnace is used to prepare gray cast iron according to the actual production method of gray cast iron, and the inoculated molten iron is added to prepare gray cast iron. The tensile test is compared with the gray cast iron treated with rare earth. The specific addition of inoculant is shown in Table 1.

| Furnace No. | 1 | 2 | 3 | 4 | 5 |

| Si-Fe alloy addition /% | 0.5 | / | / | / | / |

| Addition amount of rare earth alloy /% | / | 0.1 | 0.2 | 0.25 | 0.3 |

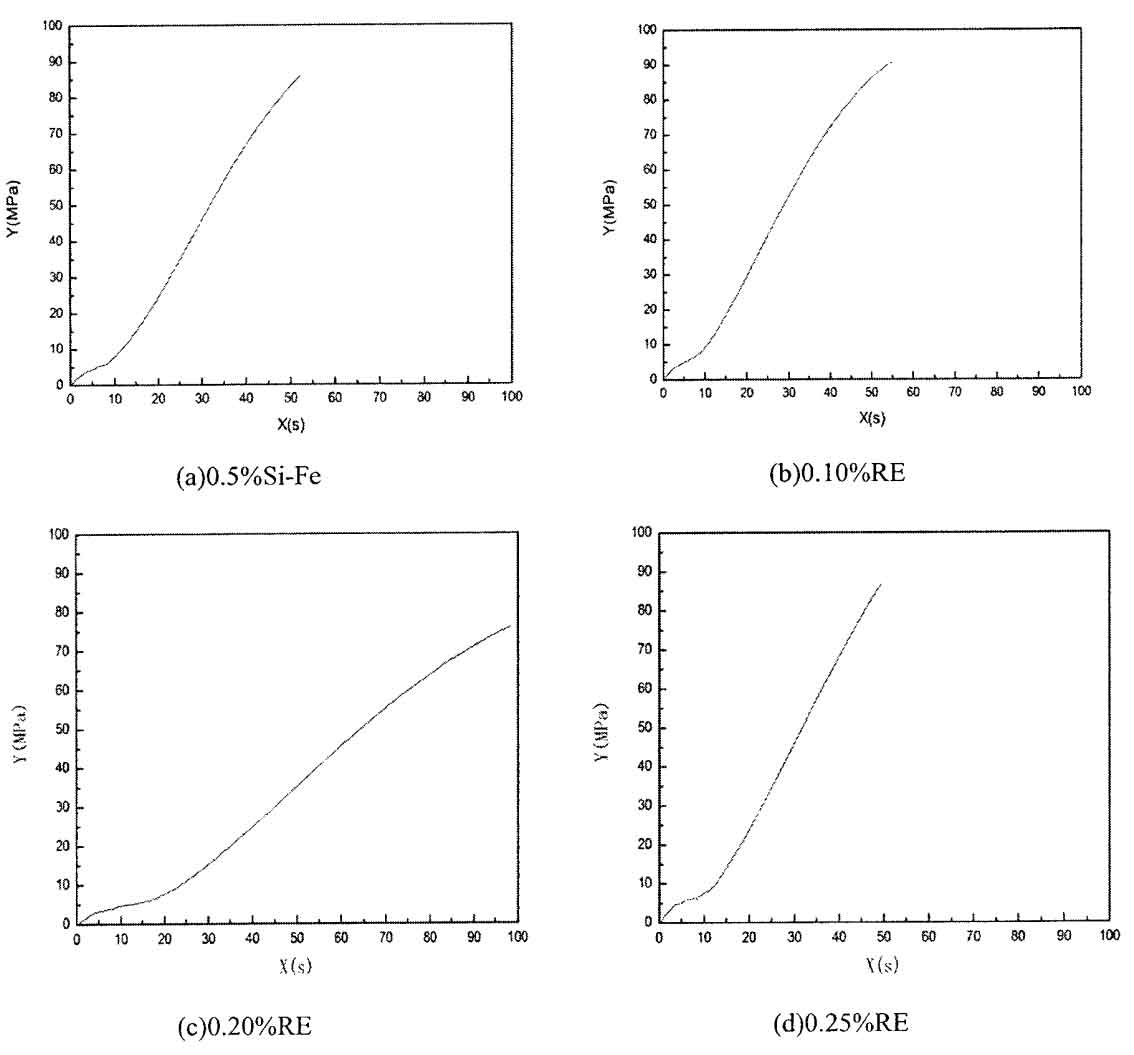

According to the tensile experimental analysis curve of low carbon equivalent gray cast iron (as shown in Figure 1), although low carbon equivalent gray cast iron has plastic deformation at the initial stage of tensile, it still belongs to the category of brittle fracture.

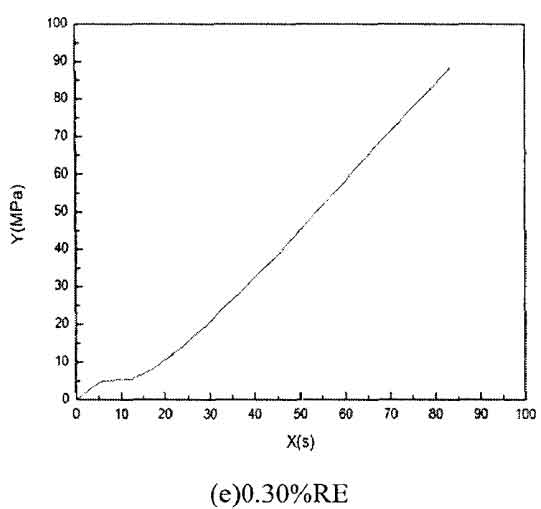

From table 2 and its corresponding figure 2, it can be seen that rare earth inoculation has a more obvious effect on the tensile strength of low carbon equivalent gray cast iron compared with ferrosilicon inoculation. When the amount of rare earth alloy is added, the tensile strength is significantly higher than that of Gray Cast Iron Inoculated with ferrosilicon; With the increase of the amount of rare earth alloy, the tensile strength of gray cast iron decreases, and reaches the lowest when the amount of rare earth ferrosilicon is 0.2%. When the amount of rare earth exceeds 0.2%, then the tensile strength of gray cast iron increases again with the increase of the amount of rare earth ferrosilicon.

| Furnace No. | 1 | 2 | 3 | 4 | 5 |

| Si-Fe alloy addition /% | 0.5 | / | / | / | / |

| Addition amount of rare earth alloy /% | 0 | 0.1 | 0.2 | 0.25 | 0.3 |

| Maximum tensile strength / MPa | 255 | 275 | 240 | 280 | 265 |