1.Test equipment

The equipment used in the test includes: P-1 metallographic test polishing machine sx-4-10 high temperature box resistance furnace, hr-150a Rockwell hardness tester, jbn-230 pendulum impact tester, microcomputer controlled electronic universal testing machine and optical microscope.

2.Composition and microstructure analysis of high chromium cast iron

Use wire cutting to cut small samples with the size of 10mmx10mm along the longitudinal section of the test block as metallographic structure observation samples; First select a certain section of the small sample, carry out pre grinding, rough grinding and fine grinding respectively, then apply chromium trioxide polishing solution for mechanical polishing, and prepare the corrosive solution composed of picric acid and 4% nitric acid ethanol. After the sample is immersed in the corrosive solution, observe the microstructure and carbide of high chromium cast iron under the optical microscope, Photos were taken to analyze the effect of modifier on the microstructure of eutectic carbide in high chromium cast iron.

3.Heat treatment process of high chromium cast iron

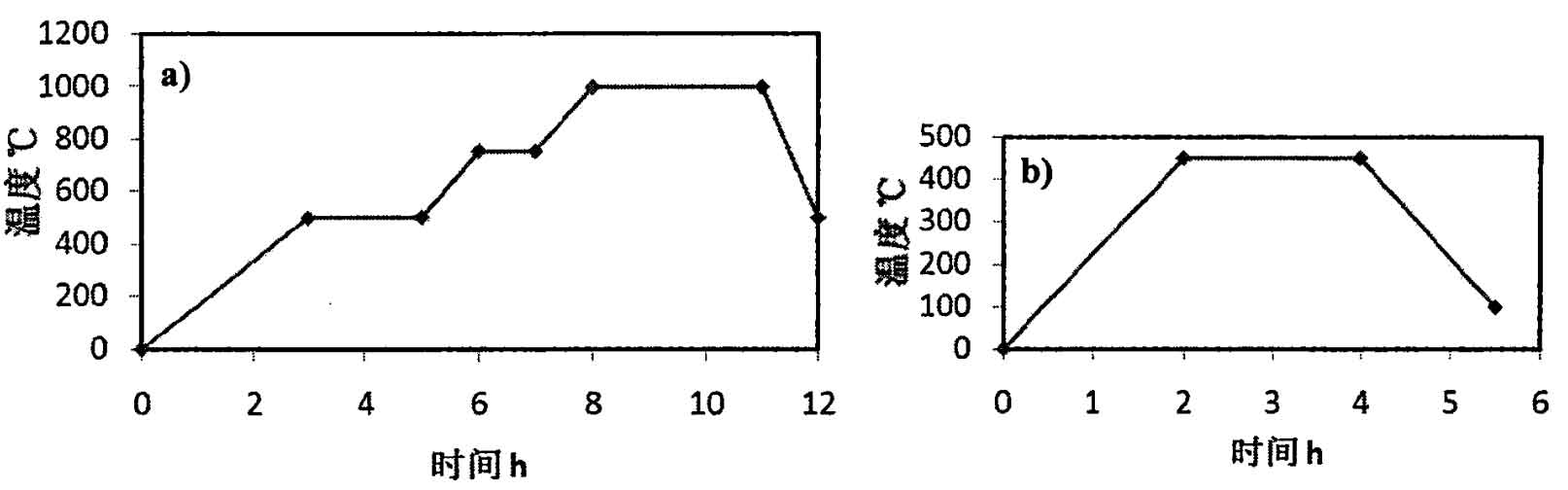

In this experiment, three high chromium cast iron samples with the size of 10mmx10mmx55mm were selected before and after modification. Six as cast samples were put into sx-4-10 high temperature box type resistance furnace for 1000 ° C quenching and 4500 ° C tempering. The purpose of this experiment is to study the effect of modifier on the microstructure and properties of heat treated high chromium cast iron. See Fig. for heat treatment process.

4.Performance test of high chromium cast iron

1). Measure the hardness of samples on hr-150a Rockwell hardness tester, measure 5 points of each sample, and take the average value;

2). Conduct impact test on 10mmx10mmx55mm notchless impact specimen on jb230 pendulum impact tester to determine its impact toughness value α K;

3) The non notched impact specimen of 20mmx30mmx170mm is tested on the microcomputer controlled electronic universal testing machine for bending strength;