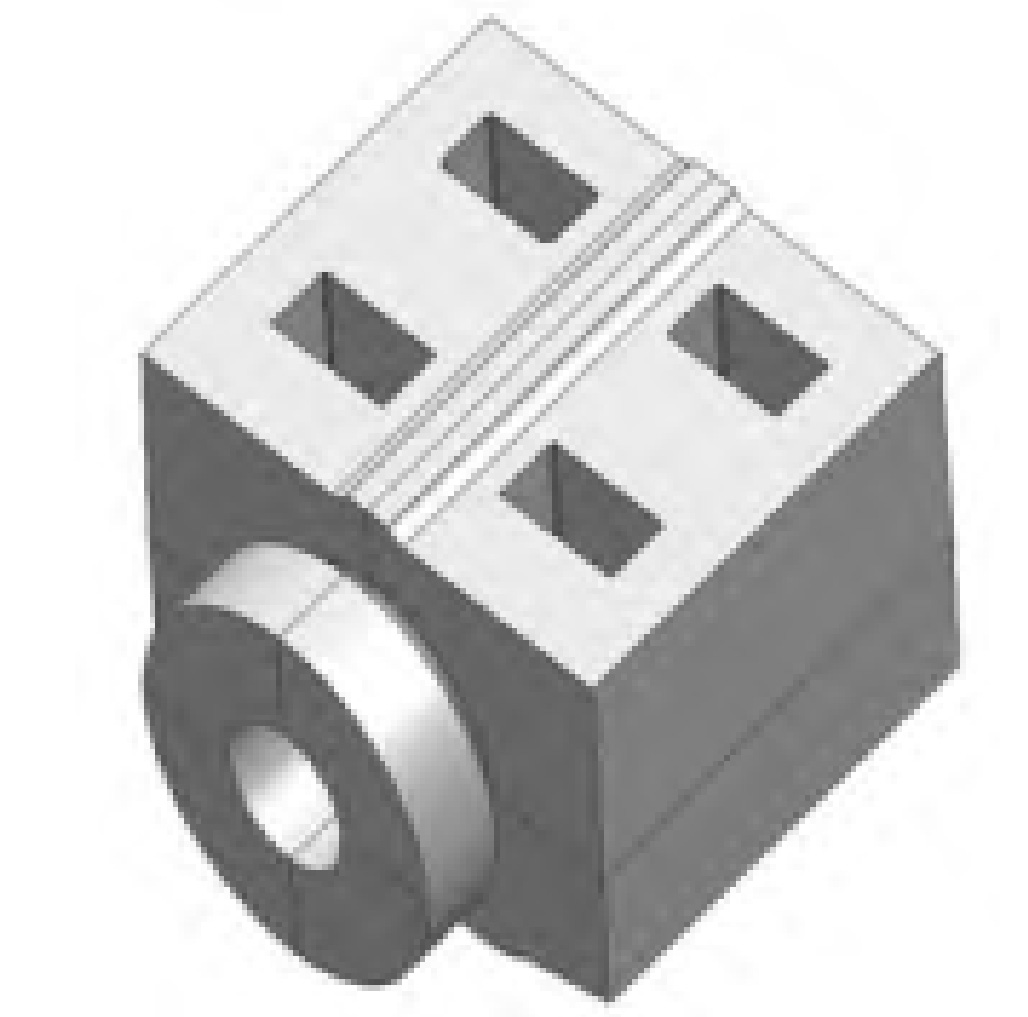

The research project product is a cast steel component for the supporting shell of a large-scale oil and gas wellhead blowout preventer (see figure), which belongs to the core component of oil and gas deep well drilling. The shell material is ASTM A487 Grade 4, material group P is 11 A, and the main components are shown in Table 1. According to the carbon equivalent calculation formula recommended by the International Welding Society, if the carbon equivalent value is greater than 0.4%, the steel has a greater tendency to harden and poor weldability. The low alloy high-strength steel with ASTM A487 Grade 4 has a carbon equivalent of 0.77% and a high tendency to harden, making it prone to cold crack defects. Therefore, the selection of welding materials, control of welding parameters, and post weld heat treatment process are key points for controlling welding quality.

For ASTM A487 Grade 4 material, the main consideration is whether the performance of the welding material can meet the requirements of the base metal and the post weld heat treatment process. Because the steel castings have very high requirements for the hardness uniformity of the three welding zones (body, welding zone and Heat-affected zone), the required value is 207 HB~237 HB, and the difference range is only 30 HB

| Element | C | Si | Mn | P | S | Cr | Ni | Mo |

| Standard | 0.25~0.33 | 0.4~0.7 | 0.8~1.2 | ≤0.025 | ≤0.025 | 0.5~1 | 0.4~0.8 | 0.25~0.45 |

The welding process of quality heat treatment after welding in as cast condition is to ensure that the weld and its Heat-affected zone have sufficient SCC resistance, and the Ni content in the electrode composition shall not exceed 1%. The principle of composition matching shall be adopted to select appropriate welding materials. The welding process of quality heat treatment after welding ultimately selected E10015-G improved welding material as the experimental welding material, and the composition of the welding material is shown in Table 2.

| AWS level | C | Si | Mn | P | S | Cr | Ni | Mo |

| E10015-G | 0.13 | 0.42 | 1.59 | 0.010 2 | 0.001 6 | 1.62 | 0.51 | 0.55 |

| E9015-B3 | 0.083 | 0.22 | 0.83 | 0.009 | 0.006 | 2.25 | 0.05 | 1.06 |

The difficulty in designing the post weld heat treatment welding process in the quenched and tempered state is to choose welding materials with equal strength. Therefore, the main consideration is to consider welding materials with equivalent or higher CE standards than the base metal. However, excessive CE values of the welding materials can lead to a significant difference in hardness between the repair area and the base metal, which is contrary to the requirements of steel castings. Through screening, the welding process of post weld stress relief heat treatment after welding in the quenched back state ultimately selected E9015-B3 improved welding material as the experimental welding material, and the composition of the welding material is shown in Table 2.