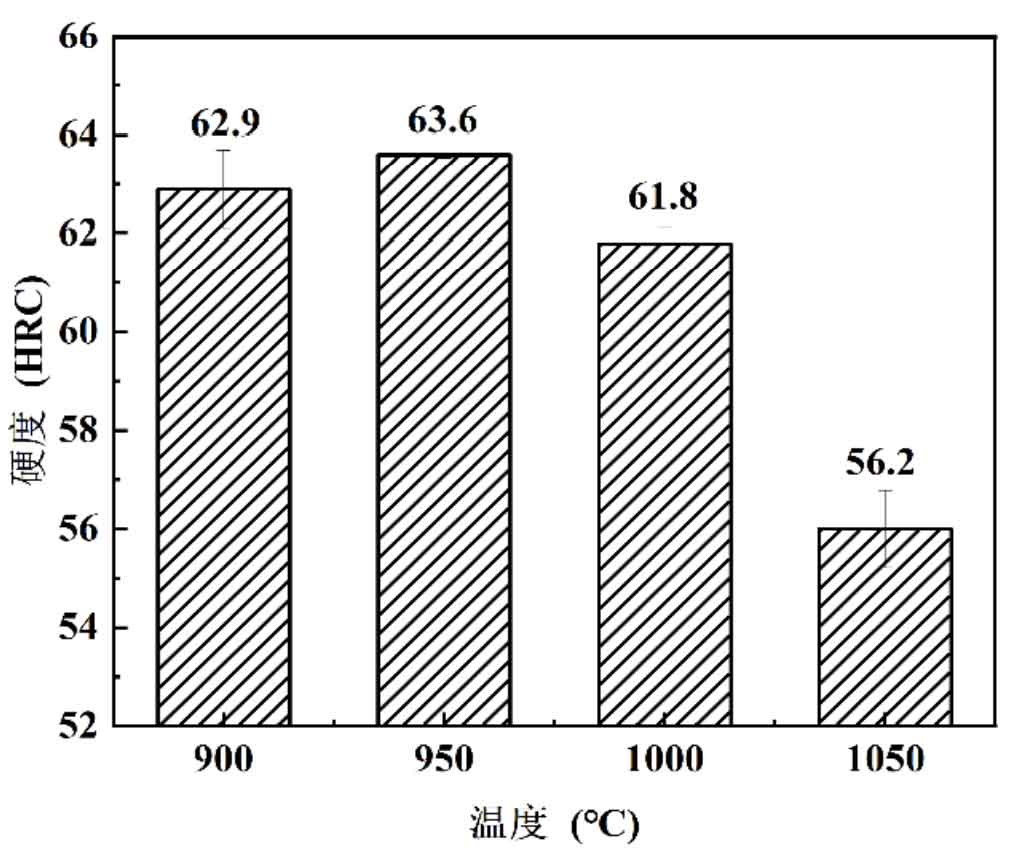

As cast, the hardness of high chromium cast iron is 52.2 HRC. Figure 1 shows the effect of quenching temperature on the hardness of high chromium cast iron. It can be seen from Figure 1 that after quenching treatment, the hardness of high chromium cast iron in heat treatment state is significantly higher than that in cast state. After quenching, the macro hardness and micro hardness of high chromium cast iron first increase and then decrease with the quenching temperature. At 950 ℃, the hardness reaches the maximum value of 63.6 HRC. As the temperature continues to rise, the hardness decreases. At 1050 ℃, the hardness decreases significantly, which is 56.2 HRC.

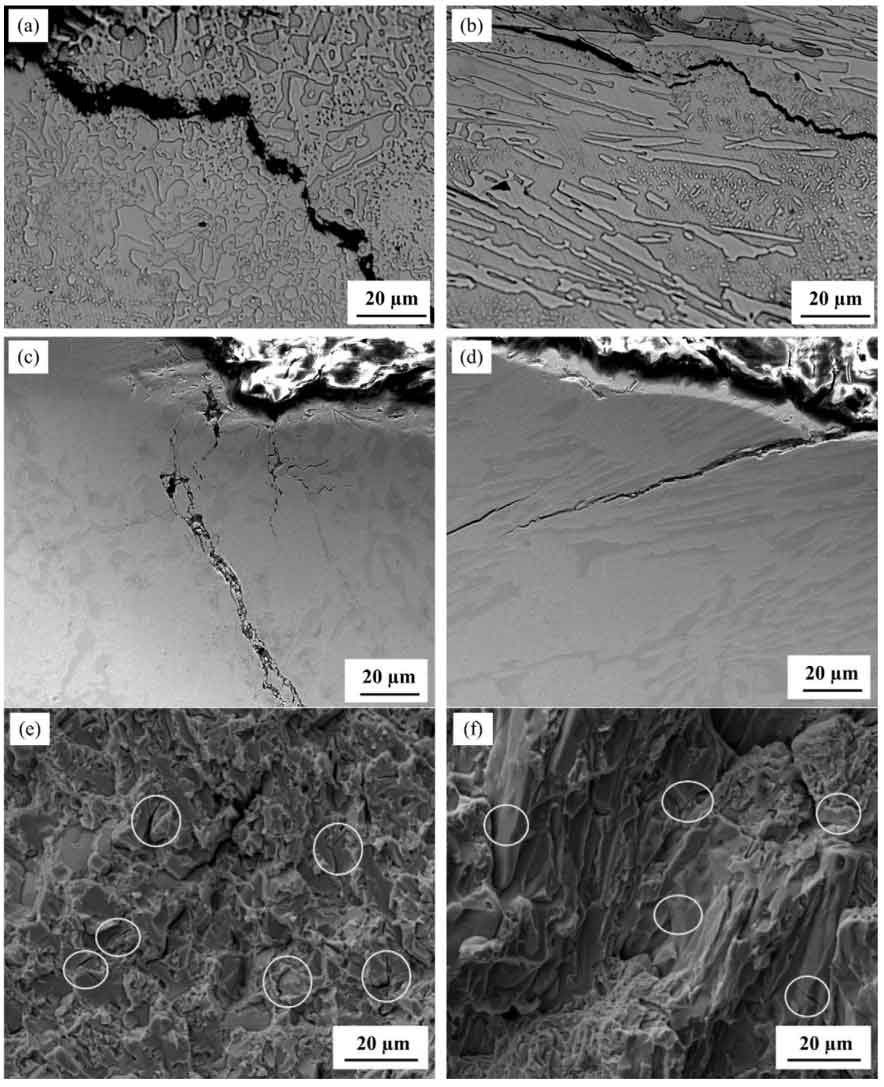

Note: The microcrack in the microstructure are marked by circle

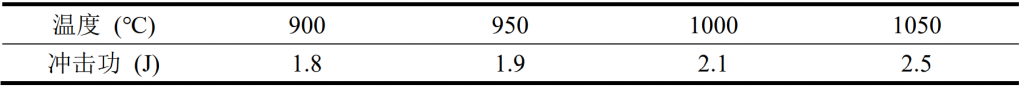

As shown in the table, the effects of different quenching temperatures (900 ℃ – 1050 ℃) on the impact properties of high chromium cast iron are shown. It can be seen from the table that at 900 ℃ – 1000 ℃, there is no obvious change in impact energy with the increase of quenching temperature. At 1050 ℃, the impact property increases slightly. That is, quenching temperature has little effect on the impact properties of high chromium cast iron.

In order to observe the internal crack propagation, the impact fracture of high chromium cast iron was longitudinally polished and corroded with 4 vol.% nitric acid alcohol to obtain the optical structure diagram and scanning electron microscope diagram as shown in Fig. 2 (A-D). It can be seen from Fig. 2 (A-D) that the microcrack continues to extend along the interface between eutectic carbide (M7C3) and matrix after passing through plate-like and massive eutectic carbides. It can be clearly observed from Fig. 2 (C-D) that there are microcracks in the matrix and eutectic carbide. As shown in Figure 2 (E-F), the impact fracture morphology is shown by SEM. From the figure, it can be seen that there is no dimple at the fracture of high chromium cast iron, which shows brittle fracture. There are microcracks in the matrix and eutectic carbide. The circle in the figure marks the microcrack in the microstructure at the fracture.