1. Phase composition of cast A356.2 (Sc, La) aluminum alloy

It can be seen from the XRD analysis and test results of aluminum alloy (Fig. 1) that the diffraction peak of Al3Sc phase is very weak, and the precipitated Al3Sc phase is relatively small, indicating that the addition of rare earth La prevents the formation and precipitation of Al3Sc phase.

2. Effect of rare earth Sc and La on as cast microstructure of alloy

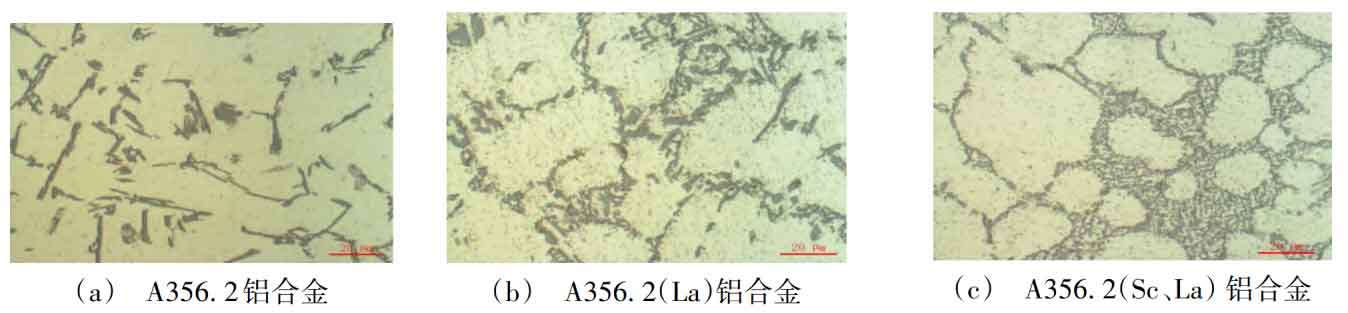

It can be seen from Fig. 1 (a) that when rare earth elements are not added, most of the eutectic silicon in the cast A356.2 aluminum alloy is in the form of needle flakes, and a few are in the form of blocks. The average size of eutectic silicon is 13.6 μ m. It is relatively thick. After adding 0.14% La to the alloy, the morphology of eutectic silicon in the cast A356.2 (La) aluminum alloy was improved. Most of the eutectic silicon was blocky, and a few was strip. The eutectic silicon was refined, and the average size was reduced to 6.3 μ M [Figure 1 (b)]. Fig. 1 (c) shows the microstructure of the cast A356.2 (Sc, La) aluminum alloy added with two rare earth elements 0.38% Sc+0.14% La. At this time, eutectic silicon is completely transformed into uniform and fine granular structure, and the average size is only 2.3 μ m。 This shows that the addition of rare earth element La alone in the alloy has a certain refining effect on eutectic silicon grains, but the refining effect is limited, and the addition of two rare earth elements Sc and La has a stronger refining effect on eutectic silicon.

3. Relationship between rare earth elements Sc, La and mechanical properties of alloys and eutectic silicon

The influence of rare earth elements Sc and La on the mechanical properties and eutectic silicon of cast A356.2 aluminum alloy is shown in the table. It can be seen that the average size of eutectic silicon of cast A356.2 aluminum alloy without adding rare earth elements is 13.6 μ m. Poor mechanical properties; After adding 0.14% La, the average size of eutectic silicon of the cast A356.2 (La) alloy formed decreases to 6.3 μ m. Its tensile strength and elongation are improved; The eutectic silicon of cast A356.2 (Sc, La) alloy is refined to 2.3 μ m. The tensile strength and elongation are increased to 181.62 MPa and 4.0% respectively. Compared with the addition of cast A356.2 (La) alloy, the refinement effect is better and the mechanical properties are higher. Therefore, the strengthening of rare earth elements Sc and La on cast aluminum alloys belongs to the fine-grained strengthening of eutectic silicon. The refining mechanism of Sc and La on eutectic silicon is:

(1) The combination of Al and Sc forms Al3Sc phase, Al3Sc phase and matrix α- The lattice type and parameters of Al phase are similar, which can be used as heterogeneous nucleation core to refine α The grains of Al phase and the heterogeneous nucleation of Al3Sc phase during alloy solidification increase the nucleation number in alloy melt, thus refining α- Grain size of Al phase, Sc pair α- The refinement of Al phase is accompanied by the refinement of eutectic silicon phase, α- The increase of Al phase refinement and quantity leads to the increase of resistance in all directions, which makes it difficult for eutectic silicon to grow up, thus making eutectic silicon become fine particles;

(2) The rare earth La phase has a strong affinity with Si. It is adsorbed at the front of the Si phase growth interface, preventing the growth of Si phase.

4. Distribution of rare earth elements Sc and La in the alloy

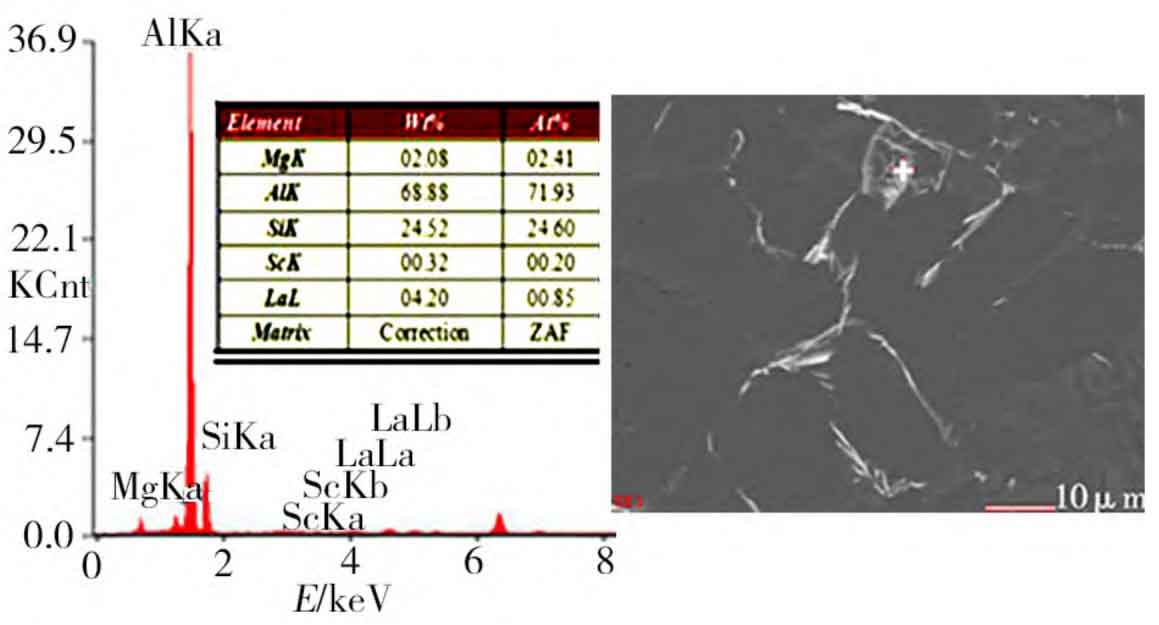

It can be seen from the SEM microstructure of the cast A356.2 (Sc, La) aluminum alloy in Fig. 2 that there are some bright white second phases distributed in the alloy, which are irregular in shape. According to the energy spectrum analysis in Fig. 2 (b), the chemical composition of the bright white second phase is 68. 88Al-24.52Si-0. 32Sc-4. 201La-2. 08Mg, indicating that the second phase is related to rare earth Sc and La.

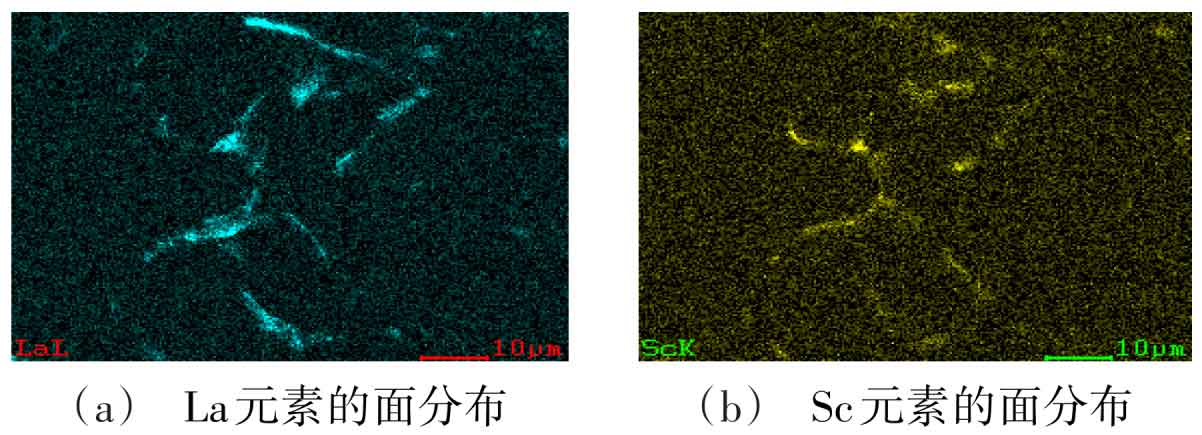

In order to understand the distribution of rare earth Sc and La in aluminum alloy, the solidification structure of cast A356.2 (Sc, La) aluminum alloy was analyzed by surface scanning of Sc and La elements. The results are shown in Figure 3. It can be seen that different shapes of Sc phase and La phase appeared in the alloy microstructure, which are distributed dispersedly and relatively small. The average sizes of Sc phase and La phase are 3.5 and 4.5 μ m。 The shape of rare earth element Sc varies greatly, except for some solid solutions α- In addition to Al phase, there is a part of Al3Sc phase in the form of second phase particles, which is dispersed in the matrix and plays a role in dispersion strengthening in aluminum alloys. In a word, the strengthening of aluminum alloy by rare earth Sc and La is the result of the combination of dispersion strengthening and fine grain strengthening.