This article focuses on the application of casting element, a novel material, in the foundry production of automotive brake discs. It elaborates on the properties, advantages, and practical applications of casting element, providing a comprehensive understanding of its significance in the automotive casting industry. Through detailed case studies and data analysis, the article demonstrates how casting element can improve casting quality, reduce emissions, and enhance production efficiency.

1. Introduction

Automotive brake discs are crucial components in the vehicle’s braking system, ensuring safety and reliable performance. The foundry production of brake discs requires high – quality materials and precise manufacturing processes. In recent years, the demand for more environmentally friendly and efficient casting materials has led to the exploration and application of new substances. Casting element, a patented material developed by Shandong Xuguang Derui High – Tech Materials Co., Ltd., has emerged as a promising alternative to traditional casting materials such as coal powder and bentonite in the production of automotive brake discs.

2. Introduction to Casting Element

2.1 Composition

Casting element is a composite material composed of high – quality bentonite, high – carbon environmentally friendly anti – sticking sand materials that replace coal powder, α – starch, cellulose, and other substances. It combines the characteristics of mixed soil and coal – powder substitute materials, with a preparation method different from that of ordinary mixed soil. This unique composition endows casting element with excellent performance in foundry applications.

| Component | Function |

|---|---|

| High – quality bentonite | Provides bonding strength in the molding sand |

| High – carbon environmentally friendly anti – sticking sand material | Replaces coal powder to prevent sand – sticking during casting, reducing pollution |

| α – starch | Improves the performance of the molding sand, such as strength and fluidity |

| Cellulose | Adjusts the physical properties of the molding sand |

2.2 Model and Technical Indicators

Casting element comes in various models, each with specific technical indicators. The main indicators include blue – absorption capacity, wet compressive strength, hot – wet tensile strength, micro – volatility, volatility, bright carbon content, and particle size passing rate. For the production of brake discs and brake drums, the XZ80 model of casting element is recommended by the manufacturer. The detailed technical indicators of different models are shown in Table 1.

| Model | Blue – absorption Capacity (g/100 g) | Wet Compressive Strength (kPa) | Hot – Wet Tensile Strength (kPa) | Micro – Volatility (%) | Volatility (%) | Bright Carbon (%) | Particle Size 140 Mesh Passing Rate (%) |

|---|---|---|---|---|---|---|---|

| XZ50 | ≥20 | ≥70 | 2.8 – 3.3 | 10 – 12 | 15 – 23 | 6 – 8 | ≥90 |

| XZ60 | ≥22 | ≥80 | 3.0 – 3.5 | 10 – 12 | 14 – 22 | 5 – 7 | ≥90 |

| XZ65 | ≥25 | ≥85 | 3.0 – 3.5 | 10 – 12 | 12 – 20 | 4 – 6 | ≥90 |

| XZ70 | ≥27 | ≥90 | 3.0 – 3.8 | 10 – 12 | 11 – 19 | 4 – 6 | ≥90 |

| XZ75 | ≥28 | ≥95 | 3.2 – 3.8 | 10 – 12 | 10 – 18 | 3 – 5 | ≥90 |

| XZ80 | ≥30 | ≥95 | 3.2 – 3.8 | 10 – 12 | 9 – 18 | 3 – 5 | ≥90 |

| XZ85 | ≥30 | ≥100 | 3.2 – 3.8 | 10 – 12 | 8 – 16 | 3 – 4 | ≥90 |

3. Green, Environmental – friendly, and Low – Emission Characteristics

3.1 Reduction of Harmful Gas Emissions

One of the significant advantages of casting element is its ability to reduce harmful gas emissions. Traditional casting processes using coal powder and bentonite produce a large amount of harmful gases, which cause air pollution and black pollution in the workshop. Casting element uses high – molecular polymers and natural plant – based environmentally friendly high – carbon materials to replace coal powder as the anti – sticking sand material.

The test results of a casting workshop in Shandong Province are shown in Table 2. The data clearly indicate that the harmful gas emissions from the casting element – based molding sand are significantly lower than those from the coal – powder and bentonite – based molding sand. This reduction in harmful gas emissions not only improves the working environment in the foundry but also contributes to environmental protection.

| Detection Date | Detection Item | Standard Code | Standard Method | First Test | Second Test | Third Test |

|---|---|---|---|---|---|---|

| April 17, 2020 | SO₂ | HJ57 – 2017 | Fixed – potential electrolysis method | Measured Concentration: 6 Emission Rate: 0.0598 | Measured Concentration: 6 Emission Rate: 0.0597 | Measured Concentration: 6 Emission Rate: 0.0596 |

| April 17, 2020 | ∑s = 1³ | HJ734 – 2014 | Gas chromatography – mass spectrometry | Measured Concentration: 0.014 Emission Rate: 0.0001 | Measured Concentration: 0.016 Emission Rate: 0.0002 | Measured Concentration: 0.015 Emission Rate: 0.0001 |

| April 17, 2020 | p – Xylene | HJ734 – 2014 | Gas chromatography – mass spectrometry | Measured Concentration: 0.010 Emission Rate: 0.0001 | Measured Concentration: 0.017 Emission Rate: 0.0002 | Measured Concentration: 0.010 Emission Rate: 0.0001 |

| April 17, 2020 | o – Xylene | HJ734 – 2014 | Gas chromatography – mass spectrometry | Measured Concentration: 0.016 Emission Rate: 0.0002 | Measured Concentration: 0.026 Emission Rate: 0.0003 | Measured Concentration: 0.016 Emission Rate: 0.0002 |

| April 17, 2020 | Toluene | HJ734 – 2014 | Gas chromatography – mass spectrometry | Measured Concentration: 0.064 Emission Rate: 0.0006 | Measured Concentration: 0.082 Emission Rate: 0.0008 | Measured Concentration: 0.055 Emission Rate: 0.0005 |

| May 20, 2020 | SO₂ | HJ57 – 2017 | Fixed – potential electrolysis method | Measured Concentration: 3 Emission Rate: 0.0301 | Measured Concentration: 3 Emission Rate: 0.0300 | Measured Concentration: 3 Emission Rate: 0.0299 |

| May 20, 2020 | ∑s = 1³ | HJ734 – 2014 | Gas chromatography – mass spectrometry | Measured Concentration: 0.009 Emission Rate: 0.0001 | Measured Concentration: 0.011 Emission Rate: 0.0001 | Measured Concentration: 0.014 Emission Rate: 0.0001 |

| May 20, 2020 | p – Xylene | HJ734 – 2014 | Gas chromatography – mass spectrometry | Measured Concentration: 0.008 Emission Rate: 0.0001 | Measured Concentration: 0.013 Emission Rate: 0.0001 | Measured Concentration: 0.008 Emission Rate: 0.0001 |

| May 20, 2020 | o – Xylene | HJ734 – 2014 | Gas chromatography – mass spectrometry | Measured Concentration: 0.012 Emission Rate: 0.0001 | Measured Concentration: 0.011 Emission Rate: 0.0001 | Measured Concentration: 0.012 Emission Rate: 0.0001 |

| May 20, 2020 | Toluene | HJ734 – 2014 | Gas chromatography – mass spectrometry | Measured Concentration: 0.048 Emission Rate: 0.0005 | Measured Concentration: 0.011 Emission Rate: 0.0001 | Measured Concentration: 0.014 Emission Rate: 0.0001 |

Note: On April 17, 2020, the clay sand workshop used the bentonite and coal – powder process for wet – type sand molding. On May 20, 2020, the clay sand workshop used the casting element process for wet – type sand molding.

3.2 Reduction of Solid Emissions

In modern foundry workshops, sand treatment dust and waste old sand are the main solid emissions. The high – temperature pouring of traditional molding sand leads to a large amount of solid powder burnout, increasing the dust in the foundry. In addition, the excess old sand in the sand treatment system needs to be discharged, resulting in a large amount of solid waste.

Casting element has a lower solid powder burnout rate during high – temperature pouring. This reduces the amount of new sand required to adjust the mud content and performance of the molding sand. As a result, the amount of dust in the sand treatment system and the amount of waste old sand are reduced.

For example, a certain company’s casting workshop has 3 Japanese – imported horizontal flaskless shoot – squeeze molding lines sharing 1 sand treatment line for the production of brake discs and brake drums. After using casting element, the auxiliary material addition rate decreased from 0.74% to 0.44%, the mud content of the molding sand decreased, and not only no new sand was needed to be added, but also 0.3% of the dust ash was recycled to maintain the mud content at the original process – required level of 10% – 12%. The solid emissions were reduced by 80%. The comparison of the molding sand ratios before and after the process change is shown in Table 3.

| Material Name | Old Sand (kg) | New Sand (kg) | Bentonite (kg) | Coal Powder (kg) | Casting Element (kg) | Dust Ash (kg) |

|---|---|---|---|---|---|---|

| Original Process | 2700 | 4 | 14 | 6 | 0 | 0 |

| Current Process | 2700 | 0 | 0 | 0 | 12 | 9 |

4. Performance of Casting Element in Clay Sand

Shandong Jianzhu University’s Professor Sun Qingzhou and others conducted experimental research to compare the XZ80 model of casting element with other similar materials and study the process performance of clay sand when mixed with casting element, bentonite, and coal powder, with or without controlling the total mud content. The research results are as follows:

- The blue – absorption capacity and volatility of 1g of casting element are the same as those of 1.271g of bentonite and coal powder I, and 1.248g of bentonite II and coal powder II.

- The variation laws of the wet compressive strength and permeability of the clay sand containing casting element with the change of casting element and moisture are the same as those of the clay sand containing bentonite and coal powder with the change of bentonite and moisture.

- Without controlling the total mud content, the wet compressive strength and permeability of the clay sand containing casting element are higher than those of the clay sand containing equivalent amounts of bentonite and coal powder.

- When the total mud content accounts for 13% of the mass of the molding sand, the wet compressive strength of the clay sand containing casting element is higher than that of the clay sand containing equivalent amounts of bentonite and coal powder, and the permeability is slightly higher or equal.

5. Applications in the Production of Brake Discs and Brake Drums

The experimental results of casting element in clay sand are consistent with the production practice of 10 companies in Yantai, Longkou, and Laizhou. When the molding sand is required to achieve the same wet compressive strength and anti – sticking sand effect, the actual addition amount of casting element is lower than that of bentonite plus coal powder. When the addition amount is the same as that of bentonite plus coal powder, the comprehensive performance of the molding sand is improved, and the quality of the castings is enhanced. The following are specific case studies.

5.1 Case One

A company’s casting workshop uses 4 Japanese – imported horizontal flaskless shoot – squeeze molding lines to produce automotive brake discs and brake drums. Using coal powder and bentonite, the casting qualification rate was 93%, with gas – hole defects accounting for about 80% of the total waste products. The company took various measures such as increasing the pouring temperature, enlarging the gas – outlet area, reducing the gas – generating amount of the sand core, replacing the carburizer and inoculant, improving the quality of the scrap steel, and increasing the particle size of the molding sand to reach the annual target of a 95% casting qualification rate, but with little effect.

After using casting element, after more than a month of cyclic use of the molding sand, under the condition that the process requirements such as the compacting rate, wet compressive strength, effective bentonite content, ignition loss, and volatility of the molding sand remained unchanged, the addition amount of casting element was less than the sum of the original bentonite and coal powder. The mud content of the molding sand decreased from 11.5% – 13% to 10% – 12%, and the moisture content decreased from 3.4% – 3.8% to 3.0% – 3.5%. The gas – hole waste products of the castings were significantly reduced. Later, on the advice of the casting element application engineer, the compacting rate of the molding sand at the discharge port of the mixer was reduced from (38 ± 2)% to (34 ± 2)%, and the moisture content of the molding sand decreased to 2.8% – 3.3%. There was no increase in the number of sand – hole defects in the castings and no decline in the mold – release performance. The gas – hole waste products of the castings were further reduced, and the qualification rate finally stabilized at 95% – 96%.

5.2 Case Two (Continued)

A company’s casting workshop uses two Japanese – imported vertical parting flaskless shoot – squeeze molding lines to produce automotive brake discs and brake drums. The sand mold size is 500 mm x 400 mm x 250 mm, with 360 molds per hour. It is specialized in producing single – piece brake discs (solid discs) and brake drums without cores, with one casting per mold and a sand – to – iron ratio of 6:1. When using coal powder and bentonite, there was a contradiction between increasing the wet compressive strength of the molding sand and improving the collapsibility of the mold.

The vertical molding mold has no sand box support and conveying trolley. The entire string of sand molds arranged on the conveying grid is pushed forward by the hydraulic system. If the wet compressive strength of the molding sand is slightly low, the sand mold will be squeezed and cracked during the pushing process, which will affect the production efficiency. To ensure the smooth progress of the production process, a higher wet compressive strength of the molding sand is required. However, the clay sand has a higher residual strength than the resin sand, and its collapsibility and sand – removal performance are lower than those of the resin sand. The cast blank holes have more adhered sand, which increases the workload of subsequent cleaning. To improve the collapsibility and sand – removal performance of the molding sand, the wet compressive strength needs to be reduced, but this will increase the risk of the mold being crushed.

The company tried to solve this problem by adding more bentonite to increase the wet compressive strength and compacting rate of the molding sand and adding more coal powder to improve the collapsibility and sand – removal performance. However, as the mud content and moisture of the molding sand increased, the collapsibility and sand – removal performance of the molding sand deteriorated, and the problems of adhered sand and sand – sticking in the blank holes of the castings became more serious. At the same time, the amount of adhered sand in other parts of the castings also increased, and the sand treatment system was in a serious shortage. Under normal circumstances, without the addition of core sand and with a sand – to – iron ratio of 6:1, adding 1.5% – 3.0% of new sand can maintain the sand volume balance of the sand treatment system. Due to the shortage, the company’s new sand addition rate was as high as 5% – 10%. Sometimes, to reduce costs, the company often purchased the old sand discharged from other companies’ brake disc and brake drum molding lines for replenishment.

After using casting element to replace coal powder and bentonite, the addition amount of casting element was gradually reduced, and finally, it was reduced to 1/2 of the original amount of bentonite and coal powder. The wet compressive strength, mud content, and compacting rate of the molding sand returned to normal. The molding line maintained stable and normal production. The sand mold was no longer squeezed and cracked during the pushing process. Its collapsibility and sand – removal performance were improved. The problems of adhered sand and sand – sticking in the blank holes of the castings were solved. The workload of the cleaning process was reduced, and the shot – blasting time was shortened. Adding 1.5% – 3% of new sand could maintain the sand volume balance of the sand treatment system, and there was no need to add extra new sand or old sand.

5.3 Case Three

A company’s casting workshop uses 3 Japanese – imported horizontal flaskless shoot – squeeze molding lines to produce automotive brake discs and brake drums. To improve production efficiency, the company changed from one casting per mold to four castings per mold (double – layer molding process) by using partition sand cores. As a result, the amount of collapsible core sand in the molding sand increased from an average of 2% to 7%, reducing the toughness of the molding sand, increasing its brittleness, deteriorating the mold – release performance, increasing the number of waste molds, and causing a large number of defects such as sand – washing, sand – holes, and sand – inclusion in the castings.

To solve these problems, the company took measures such as increasing the effective bentonite content, adding 0.1% – 0.3% of α – starch during sand mixing, and prolonging the sand – mixing time. However, the fluidity of the molding sand decreased, and problems such as blockage of the sand – shooting barrel and incomplete filling of the sand mold occurred during production. The company could only add 1% – 3% of new sand during sand mixing to reduce the adverse effects of the collapsible core sand on the toughness of the molding sand. This not only increased the addition amount of bentonite and coal powder during sand mixing, increasing production costs, but also increased the waste sand emissions.

After using casting element to replace coal powder and bentonite in the preparation of the molding sand, the toughness and mold – release performance of the molding sand gradually recovered. The addition of new sand was cancelled, the scrap rate of castings due to sand – washing, sand – holes, and sand – inclusion decreased, and the casting qualification rate approached the level of the single – layer process.

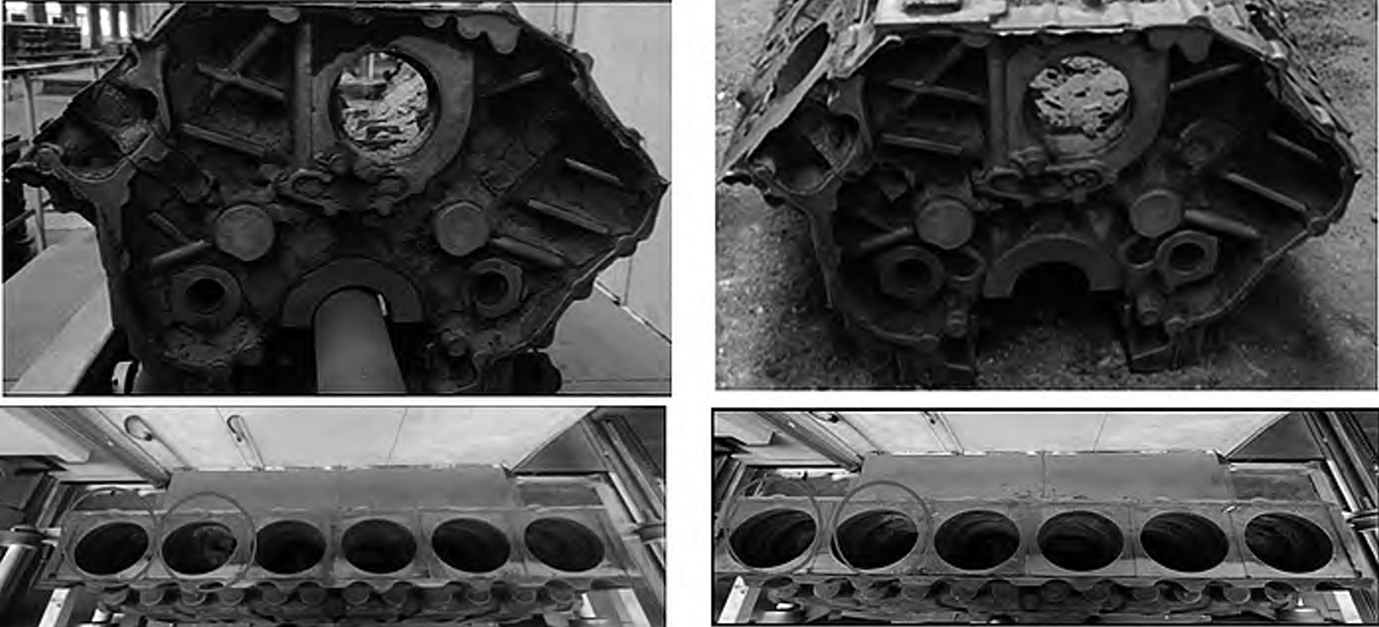

5.4 Case Four

A company’s casting workshop uses 3 Japanese – imported horizontal – parting flaskless shoot – squeeze molding lines to produce automotive brake discs and brake drums. The company used artificially sodium – modified bentonite and high – quality coal powder for sand mixing. It was found that when producing brake disc castings with a large diameter, peeling, rat – tails, veining, and slight sand – sticking defects often occurred near the root of the small end. After the castings were discharged from the single – layer sand – falling drum, some sand blocks could not be broken and scattered on the apron conveyor with the castings. When the mold was cased, the mold often deformed, resulting in casting waste products.

The high – quality bentonite in the casting element has been modified and re – treated, with high hot – wet tensile strength and good reusability. The high – carbon material replacing coal powder and α – starch can effectively reduce the thermal pressure stress of the molding sand, reducing expansion – type defects such as peeling, rat – tails, and veining in the castings. Using casting element, the strength and toughness of the molding sand are improved, and the sand mold is not easily damaged when subjected to mechanical actions such as casing and pressing iron.

The company used casting element to replace bentonite and coal powder. The addition amount of casting element was 54% less than the sum of bentonite and coal powder. No new sand was added during sand mixing, and the effective bentonite content of the molding sand remained basically the same as before. The ignition loss decreased by 0.3% – 0.5%. The peeling, rat – tails, and veining defects of the brake disc castings were completely solved. The number of unbroken sand blocks and casting deformation waste products caused by casing was greatly reduced, and the initial inspection scrap rate of the castings decreased by 60%.

6. Conclusion

Casting element is a green, environmentally friendly, and efficient molding material. It has been successfully applied in many domestic brake disc and brake drum production enterprises. Compared with the sum of coal powder and bentonite, the addition amount of casting element is less, and the emissions of harmful gases and solid waste are reduced. The mold – release performance, collapsibility, and fluidity of the molding sand are improved. Defects such as gas – holes, sand – holes, sand – sticking, peeling, rat – tails, veining, and deformation in the castings are reduced. Casting element provides a new choice for foundry enterprises to save energy, reduce consumption, improve quality, and upgrade their production processes.

In the future, with the continuous improvement of environmental protection requirements and the development of the automotive industry, the application of casting element is expected to expand further. Foundry enterprises should pay more attention to the research and application of new materials like casting element to improve their competitiveness in the market and contribute to the sustainable development of the industry.