This article delves deep into the 3D casting process design for volute – type products. Volute – type products, with their complex curved structures, pose unique challenges in the casting process. By comprehensively exploring each step of the design process, from model simplification to sand core and mold design, this paper aims to provide a detailed and practical guide for foundry engineers and designers. It also emphasizes the importance of optimizing the design to improve production efficiency and product quality, while minimizing potential casting defects.

1. Introduction

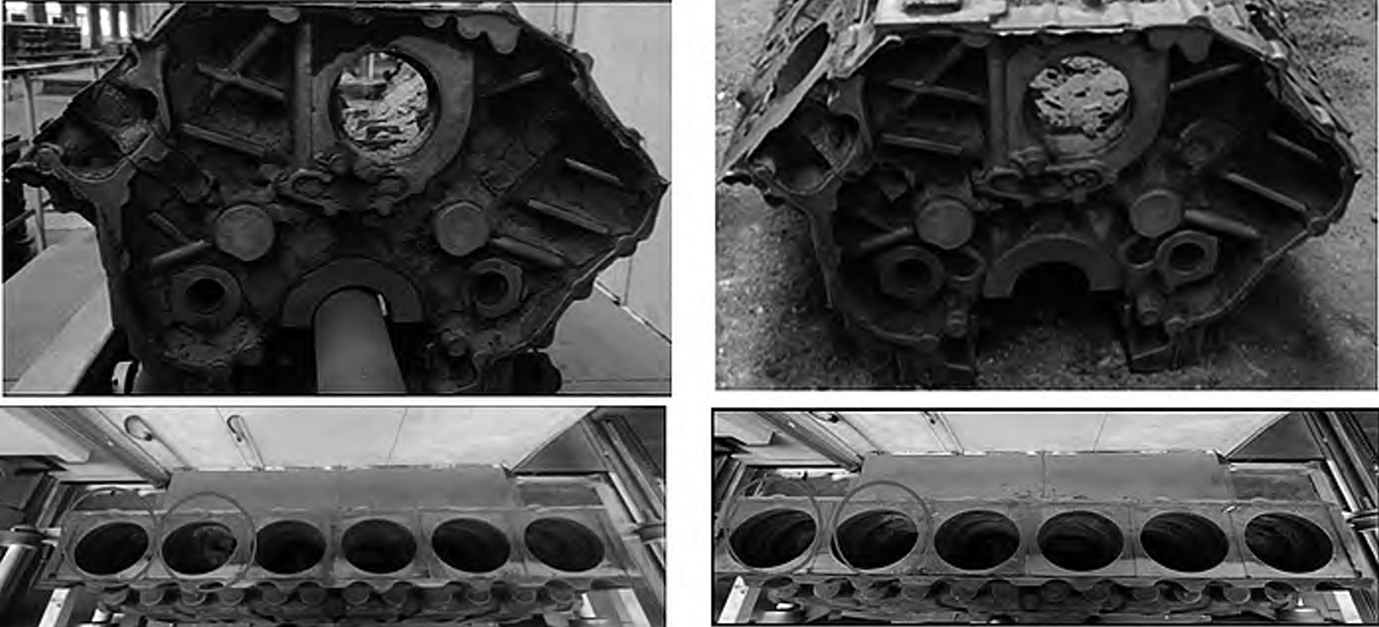

Volute – type products play a crucial role in various industries, such as fluid machinery, power generation, and automotive. Their primary function is to collect, pressurize, and direct fluids or gases. The complex shape of volutes, resembling a snail shell, makes their casting process a challenging task. Traditional casting methods often encounter issues like mold extraction difficulties, sand core handling problems, and potential casting defects. Therefore, a well – designed 3D casting process is essential to ensure the successful production of high – quality volute – type products.

2. Simplifying the Model Structure

2.1 Identifying and Removing Unnecessary Features

Before starting the casting process design, it is necessary to simplify the product model structure. This involves removing fine – machining features such as holes and grooves, as well as all fillets except for the main arc – shaped structures. These features are not directly cast and can be added later in the machining process. By deleting them, we can simplify the model and make it easier to handle during the casting process design.

| Feature | Reason for Removal | Impact on Casting Process |

|---|---|---|

| Holes and Grooves | Not directly cast; added in machining | Simplifies model, reduces complexity in mold design |

| Non – Main Fillets | For aesthetic or stress – relief purposes in final product | Facilitates mold extraction, reduces potential for mold damage |

2.2 Importance of Model Perspective

When simplifying the model, it is crucial to view the model in perspective. This allows designers to see hidden structure lines and surfaces, preventing accidental deletion of important structures. By rotating the model and using selection tools like box – selection, designers can efficiently select and remove the targeted features while maintaining the integrity of the main model structure.

3. Designing the Machining Allowance

3.1 Identifying Machining Surfaces

The first step in designing the machining allowance is to identify the machining surfaces on the volute model. This is done by referring to the customer – provided 2D drawings and marking the corresponding surfaces on the 3D model with a distinct color. After marking, a second round of model simplification is carried out, focusing on the structures formed by the marked machining surfaces.

| Structure to be Removed | Reason for Removal | Impact on Machining Allowance Design |

|---|---|---|

| Oblique Surfaces | Difficult to cast and machine; may cause sand core removal issues | Ensures proper sand core extraction and machining |

| Small – Spaced Grooves | Narrow spaces make sand core removal impossible after adding allowance | Facilitates sand core handling and casting process |

| Small Steps | Difficult to distinguish after adding fillets; may affect surface quality | Maintains surface quality and dimensional accuracy |

3.2 Adding and Verifying Machining Allowance

After simplifying the model, a backup of the model (referred to as Body 2) is created. Then, the machining allowance is added by thickening the marked machining surfaces according to the specified allowance size. As the allowance is added, the surfaces are marked with another color for verification. Once all the allowances are added, the model with the allowance is compared with Body 2 to ensure that no non – machining surfaces have been accidentally included in the allowance design.

4. Extracting the Volute Model’s Main Structure

4.1 Challenges in Extracting the Maximum Contour Line

The volute model’s wall often has structures like lifting lugs and boss seats, which can interfere with the extraction of the maximum contour line. When using the “extract curve” command in 3D modeling software, the curve may be interrupted at the connection points of these structures, resulting in an incomplete maximum contour line.

4.2 Extracting the Main Structure

To overcome this issue, the main structure of the volute model needs to be extracted first. This involves separating the additional structures on the wall from the wall itself at their junction surfaces. After separation, these structures are hidden, and the remaining volute body is the main structure. However, the junction surfaces left on the wall need to be removed to ensure that the wall surface is smooth and continuous, enabling the extraction of a complete maximum contour line.

5. Designing the Process Subsidy for the Volute Wall

5.1 Causes and Consequences of Casting Defects

Casting defects such as shrinkage porosity, gas holes, cracks, and slag inclusions are common in the casting process. Slag inclusions, in particular, often occur on the top surface of the casting due to the floating of slag in the molten metal. In the case of volute – type products, the arc – shaped vertical surface and the conical structure during the core – setting process make it difficult to detect slag or sand particles falling into the cavity.

5.2 Adding the Subsidy

To address the slag inclusion issue, a subsidy is added to the top surface of the volute model. This is done by duplicating the volute main body model, moving one copy (the subsidy body) by a certain distance (subsidy amount ‘a’) in the direction of the subsidy, and then simplifying the subsidy body by removing unnecessary parts such as flange structures. Finally, the two bodies are combined to obtain a volute main body structure with an internal and external top – surface subsidy.

| Step | Action | Purpose |

|---|---|---|

| 1 | Duplicate the volute main body | Create a base for adding subsidy |

| 2 | Move the subsidy body | Set the subsidy amount |

| 3 | Simplify the subsidy body | Ensure the integrity of the volute structure |

| 4 | Combine the two bodies | Obtain the final subsidized structure |

6. Determining the Parting Surface

6.1 Characteristics of the Volute’s Parting Surface

The parting surface of a casting product is usually located at the maximum plane or maximum contour to facilitate mold extraction. For volute – type products, the parting surface is at the maximum contour of the volute wall, which is a spiral curve due to the spiral structure of the volute wall.

6.2 Designing the Parting Surface

The design of the parting surface involves several steps. First, the maximum contour line of the volute wall is extracted. Then, this line is used as the starting point, and a sheet – like structure is created by stretching it along the mold – extraction direction. The sheet – like structure is then thickened into a solid to form the bottom template of either the upper or lower mold. The bottom template is further trimmed to match the shape of the volute main structure, and its bottom surface is adjusted to be horizontal and higher than the highest point of the volute model. Finally, the previously separated structures like lifting lugs and boss seats are combined with the volute main structure, and fillets are added according to the original model and customer drawings. The bottom template is then trimmed using the volute model with fillets to obtain the final mold structure.

| Step | Action | Key Points |

|---|---|---|

| 1 | Extract the maximum contour line | Ensure the accuracy of the contour line extraction |

| 2 | Stretch the contour line | Set the appropriate stretching distance |

| 3 | Thicken the sheet – like structure | Consider the thickness and extension for further trimming |

| 4 | Trim the bottom template | Match the volute structure and adjust the bottom surface |

| 5 | Combine structures and add fillets | Restore the original model features |

| 6 | Trim the bottom template with the volute model | Ensure proper mold – part fit |

7. Designing the Sand Core and Mold

7.1 Designing the Sand Core for the Inner Cavity

The inner cavity of the volute – type product is a spiral – shaped cavity. To form this cavity during casting, a sand core is designed. Since the inner cavity is a continuous structure with openings at the top – surface round hole, bottom – surface round hole, and pipe opening, the sand core can be designed as a single – piece snail – shaped core. Core heads are designed at the openings for positioning, except for the top – surface round hole to avoid sand – dropping during mold – closing.

7.2 Ensuring Core Stability

Due to the non – central gravity of the snail – shaped core, an internal fixture can be designed to increase the core strength, adjust the center of gravity, and guide the core – setting process. Additionally, to prevent the core from floating during the pouring process, a core – marking hole is designed at the pipe – opening core head, and a corresponding fixture for embedding the core – marking is designed on the mold to fix the core in place.

| Measure | Purpose | Impact on Casting Quality |

|---|---|---|

| Designing internal fixtures | Increase core strength, adjust center of gravity, and guide core – setting | Ensures accurate core placement and dimensional accuracy of the casting |

| Designing core – marking holes and fixtures | Prevent core floating during pouring | Reduces the risk of casting defects caused by core displacement |

8. Conclusion

The 3D casting process design for volute – type products is a complex and systematic project. By following the steps of model simplification, machining allowance design, main – structure extraction, subsidy design, parting – surface determination, and sand – core and mold design, foundry engineers can effectively avoid potential problems in the casting process. This not only improves the design efficiency but also significantly enhances the product quality, reducing the occurrence of casting defects and ensuring the reliable performance of volute – type products in various applications.