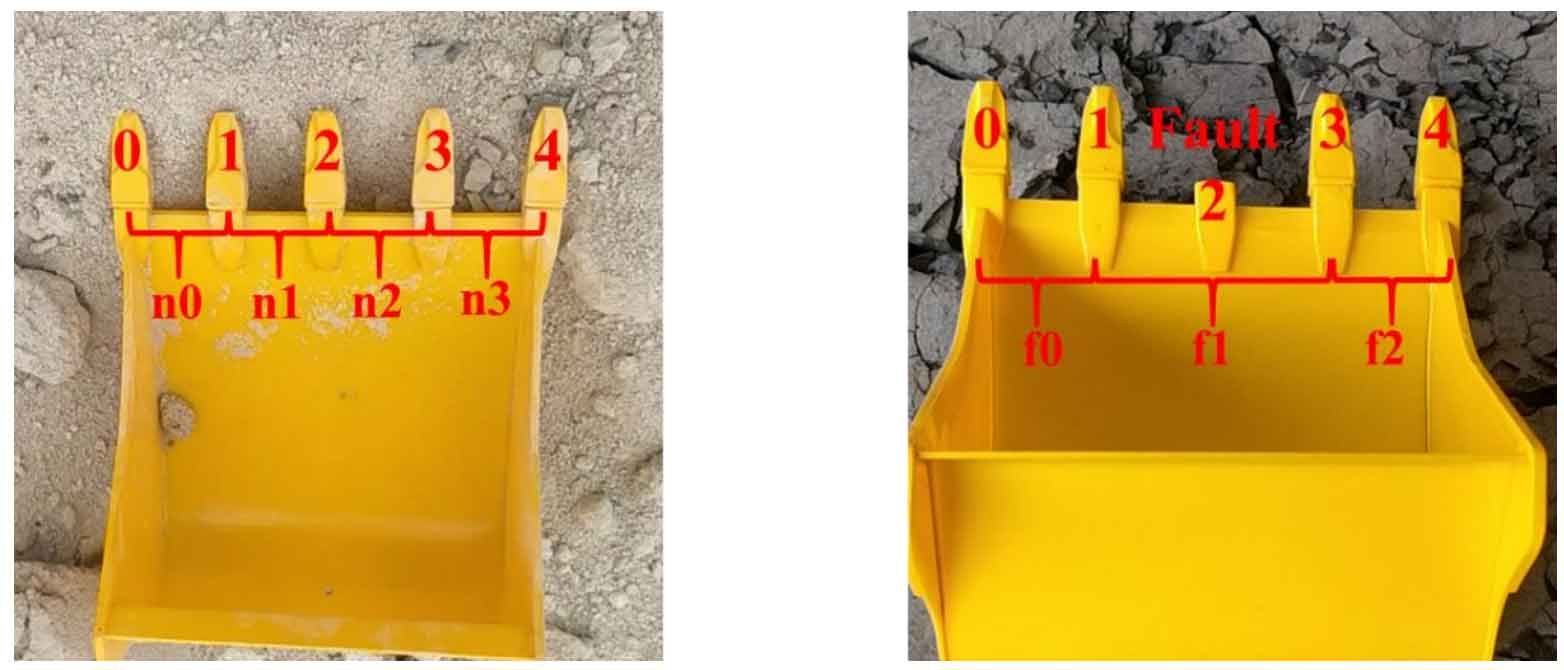

The situation of a bucket tooth fault is relatively simple, which can be divided into bucket tooth fault in the middle position and on both sides of the bucket, as shown in Figure 1.

(b) The fault is that one of the bucket teeth is at the end

(c) Fault: one bucket tooth is in the middle

If the bucket tooth fault occurs at both ends, it can be directly judged according to the matching results. When the faulty bucket teeth are at both ends, there is only one bucket tooth that can be calibrated as the end. The position of the faulty bucket tooth can be obtained by calibrating one of the end bucket teeth. As shown in Figure 2 (a), the normal bucket is equipped with five bucket teeth. When the bucket in Figure 2 (b) of the target detection procedure detects four bucket teeth, use the No. 0 bucket teeth and No. 4 bucket teeth of the normal bucket to match the bucket teeth of the failed bucket. Only the No. 4 bucket teeth of the failed bucket are matched, so the No. 0 bucket teeth of the failed bucket fail.

When the fault of the bucket tooth is in the middle position, the spacing between the two adjacent bucket teeth of the fault bucket tooth will become larger. According to this basis, the position of the fault bucket tooth can be determined. As shown in Figure 3, the target detection program detects the bucket teeth of a normal bucket, and the number of bucket teeth is 5. In Figure 3 (b), the number of bucket teeth detected is 4, and the proportion of spacing F1 in the total spacing is greater than that of intermediate spacing N1 or N2 in Figure 3 (a).