This article focuses on the manufacturing process defects of casting products used in motor train units. Through in – depth research and a series of analysis methods such as macroscopic observation, metallographic examination, and mechanical property testing, it comprehensively analyzes various types of defects. It details the causes, impacts, and preventive measures of these defects, aiming to provide a theoretical basis and practical guidance for improving the quality of casting products in motor train units.

1. Introduction

Motor train units have become an important means of transportation in modern society due to their high – speed, safety, and comfort features. Casting products play a crucial role in motor train units, being widely used in key components such as high – speed bogies, couplers, traction systems, and braking systems. These casting products are usually made of materials like cast steel, cast iron, or cast aluminum to meet the requirements of strength, stiffness, and durability during high – speed operation. However, the manufacturing process of casting products is complex, and various defects may occur, which seriously affect the performance and safety of motor train units. Therefore, it is of great significance to study the manufacturing process defects of casting products for motor train units.

2. Classification of Casting Products in Motor Train Units

2.1 Aluminum Castings

Aluminum castings are commonly used in the traction system of motor train units, such as in components like gearboxes. These aluminum castings possess good strength and toughness, enabling them to withstand the high – speed operation loads. Their excellent mechanical properties ensure the normal operation of the traction system. For example, in high – speed trains, the gearbox needs to transmit high – torque power, and the aluminum casting with proper strength and toughness can meet this requirement. Table 1 shows some typical mechanical properties of aluminum castings used in motor train units.

| Mechanical Property | Value |

|---|---|

| Tensile Strength (MPa) | 200 – 300 |

| Yield Strength (MPa) | 150 – 200 |

| Elongation (%) | 8 – 12 |

| Hardness (HB) | 60 – 80 |

| Table 1: Typical Mechanical Properties of Aluminum Castings in Motor Train Units |

2.2 Steel Castings

Steel castings are extensively applied in critical parts of motor train units, including the traction system, braking system, coupling system, and bogies. They are characterized by high strength, high toughness, and good wear resistance, which are essential for ensuring the safe operation of motor train units. In the braking system, steel castings can endure high – pressure and high – temperature conditions during braking, and their wear – resistant property guarantees a long service life. Table 2 presents the main mechanical properties of steel castings used in motor train units.

| Mechanical Property | Value |

|---|---|

| Tensile Strength (MPa) | 400 – 600 |

| Yield Strength (MPa) | 300 – 450 |

| Impact Toughness (J/cm²) | 30 – 50 |

| Hardness (HB) | 150 – 200 |

| Table 2: Main Mechanical Properties of Steel Castings in Motor Train Units |

2.3 Iron Castings

Iron castings are mainly used in components such as brake cylinder devices and brake caliper devices. They are required to have good wear resistance and corrosion resistance. In the harsh working environment of the braking system, iron castings can maintain stable performance. Table 3 shows the typical performance requirements of iron castings used in motor train units.

| Performance Requirement | Value |

|---|---|

| Wear Resistance (mg/cm²) | ≤ 10 |

| Corrosion Resistance (mm/year) | ≤ 0.1 |

| Tensile Strength (MPa) | 200 – 300 |

| Table 3: Typical Performance Requirements of Iron Castings in Motor Train Units |

3. Quality Requirements for Casting Products in Motor Train Units

3.1 Internal Quality

Casting products must be free of internal defects such as pores and inclusions. These defects can reduce the strength and durability of the castings. For example, pores in the casting can act as stress – concentration points, which may lead to crack initiation under load. To ensure internal quality, strict inspection methods such as ultrasonic testing and radiographic testing are often used during the manufacturing process.

3.2 External Quality

The surface of casting products should be free of cracks, crusts, or quenching marks. These surface defects not only affect the appearance quality of the products but also may reduce their service performance. A smooth and defect – free surface can improve the fatigue strength and corrosion resistance of the castings. Visual inspection and surface roughness measurement are common methods to control external quality.

3.3 Dimensional Accuracy

Casting products need to have high – precision dimensions that meet the design requirements. This is crucial for ensuring the proper fit between different components of the motor train unit. If the dimensional accuracy is not met, it may cause problems such as poor assembly, increased wear, and reduced performance. Dimensional inspection using precision measuring instruments is carried out to guarantee dimensional accuracy.

4. Case Analysis of Manufacturing Process Defects

4.1 Original Casting Pre – crack Defects

Take a mounting seat of a motor train unit made of cast gray iron as an example. The macroscopic morphology of its fracture surface is shown in Figure 1. The fracture surface near the crack initiation point shows no macroscopic plastic deformation, presenting a “coarse porcelain – like” appearance, which is a characteristic of brittle fracture. There are reddish – brown coverings on the local fracture surface. Through scanning electron microscopy (SEM) and energy – dispersive spectroscopy (EDS) analysis, it is found that the reddish – brown coverings are the coating on the inner wall of the sand mold during the casting process. This indicates that the mounting seat had an original casting pre – crack before use, and it cracked under overload during operation.

[Insert Figure 1: Mounting Seat Fracture Surface Macroscopic Morphology]

4.2 Original Casting Shrinkage Porosity Defects

For a coupler pawl of a motor train unit made of cast iron, the macroscopic morphology of its fracture surface is shown in Figure 2. The crack initiation position is at the U – shaped groove, which is the part with the smallest effective cross – sectional area of the pawl. SEM analysis of the fracture initiation area and the core of the pawl reveals the presence of multiple porosity and shrinkage cavity defects. This shows that the coupler pawl had original casting shrinkage porosity defects, and it cracked under overload during use.

[Insert Figure 2: Coupler Pawl Fracture Surface Macroscopic Morphology]

4.3 Original Casting Cold Shut Defects

A windscreen pull rod system adjustment sleeve of a motor train unit is made of 07Cr19Ni10 cast stainless steel. The appearance and defect position of the adjustment sleeve are shown in Figure 3. When the surface defect of the adjustment sleeve is opened, the macroscopic morphology of the fracture surface shows that the original fracture surface at the defect position is oxidized and rust – colored, while the other metal – colored areas are artificially opened fracture surfaces. This indicates that the defect on the adjustment sleeve is a casting cold shut defect.

[Insert Figure 3: Adjustment Sleeve Appearance and Defect Position]

4.4 Original Casting Hot Crack Defects

A clamping hoop of a motor train unit is made of cast steel. The appearance and defect position of the clamping hoop are shown in Figure 4. Magnetic particle inspection of the suspected defect area reveals three areas with magnetic traces. The microscopic morphology of the cross – section of the defect areas shows that the defects are in the form of cracks, and there is obvious decarburization on both sides of the cracks. This indicates that the defect of the clamping hoop is a casting hot crack.

[Insert Figure 4: Clamping Hoop Appearance and Defect Position]

4.5 Heat Treatment Process Defects

A lower swing arm base of a motor train unit is made of cast aluminum alloy. The appearance and fracture position of the lower swing arm base are shown in Figure 5. There is no obvious plastic deformation at the fracture position. After dissecting the base, shrinkage cavity defects can be seen in the core of the casting. The microscopic morphology of the lower swing arm base shows that its microstructure is in an unmodified state, with needle – like and flaky eutectic silicon cutting the continuity of the matrix, making it prone to brittle cracking under impact load.

[Insert Figure 5: Lower Swing Arm Base Appearance and Fracture Position]

4.6 Defects Caused by Welding Repair Process of Casting Defects

A clamping hoop of a motor train unit is made of E260 – 450 – MS cast steel. The appearance and defect position of the clamping hoop are shown in Figure 6. The defect is located in a local area of the assembly surface, presenting an irregularly distributed pit – like morphology. Microscopic examination of the defect area shows the presence of a welding heat – affected zone at the bottom of the pit and multiple micro – cracks on the surface of the pit. This indicates that the pit defect of the clamping hoop is caused by poor fusion between the local welded metal and the base metal, mainly due to improper welding repair process parameters.

[Insert Figure 6: Clamping Hoop Appearance and Defect Position]

4.7 Defects Caused by Poor Machining after Casting

An earthing axle box cover of a motor train unit is made of GE230N cast steel. The appearance and microscopic morphology of the defect of the axle box cover are shown in Figure 7. The defect at the magnetic trace aggregation area shows crack characteristics. The crack initiation point has no original casting defects, and there is no oxidation or decarburization on both sides of the crack. The crack propagation path is transgranular. After artificially opening the crack and observing the fracture surface with SEM, fatigue striations can be seen, indicating that the defect of the earthing axle box cover is a crack caused by stress concentration at the variable – cross – section transition during machining after casting, and it expands under alternating loads during service until a macroscopic crack is formed.

[Insert Figure 7: Axle Box Cover Appearance and Defect Microscopic Morphology]

5. Analysis and Discussion of Defects

5.1 Types of Defects in Casting Products for Motor Train Units

Based on the above – mentioned case analysis, the manufacturing process defects of casting products for motor train units mainly include original casting defects, poor microstructures, original defects not eliminated after welding repair, and defects caused by poor machining. The defect types and their corresponding characteristics are summarized in Table 4.

| Defect Type | Characteristics |

|---|---|

| Original Casting Defects | Include pre – cracks, shrinkage porosity, cold shuts, and hot cracks. These defects are formed during the casting process and can be detected by macroscopic observation, SEM, etc. |

| Poor Microstructures | Manifest as non – uniform crystal structures or improper chemical composition distributions. They can be identified through metallographic examination and affect the mechanical, physical, and chemical properties of the castings. |

| Original Defects Not Eliminated after Welding Repair | Such as non – fusion, cracks, and slag inclusions remaining after welding. These defects can be detected by non – destructive testing methods and have a negative impact on the mechanical properties, sealing performance, and corrosion resistance of the castings. |

| Defects Caused by Poor Machining | Include cracks, scratches, and dimensional inaccuracies. These defects are caused by improper machining operations and can be found through surface inspection and dimensional measurement. |

| Table 4: Types and Characteristics of Defects in Casting Products for Motor Train Units |

5.2 Impacts of Defects on Casting Products

5.2.1 Impact of Original Casting Defects

- Structural Integrity: Casting defects such as holes and cracks can damage the structural integrity of the castings, reducing their load – bearing capacity and service life. For example, pores and shrinkage porosity can lower the strength and density of the castings, while cracks can lead to fracture under stress.

- Appearance Quality: These defects can cause pits, protrusions, and pores on the surface of the castings, seriously affecting the appearance quality of the products. This not only reduces the aesthetic appearance but also may affect the market acceptance of the products.

- Service Performance: Casting defects can affect the service performance of the castings, such as reducing their wear resistance, corrosion resistance, and fatigue strength, thus affecting the reliability and safety of the products. The impacts of original casting defects are summarized in Table 5.

| Impact Aspect | Specific Impact |

|–|–|

| Structural Integrity | Reduces load – bearing capacity and shortens service life |

| Appearance Quality | Causes surface defects and affects market acceptance |

| Service Performance | Lowers wear resistance, corrosion resistance, and fatigue strength |

Table 5: Impacts of Original Casting Defects on Casting Products

5.2.2 Impact of Poor Microstructures

- Reduction in Mechanical Properties: Poor microstructures can lead to a decrease in mechanical properties such as tensile strength, yield strength, and hardness. The non – uniform crystal structure and chemical composition distribution in the metal can cause the mechanical properties of the castings to decline. For example, the castings are prone to plastic deformation and fracture during use, affecting their service life and safety performance.

- Reduction in Physical Properties: They can also reduce physical properties such as the coefficient of thermal expansion, thermal conductivity, and specific heat capacity. This can make the performance of the castings unstable in high – or low – temperature environments, affecting the safe operation of the equipment.

- Reduction in Chemical Properties: Poor microstructures may lead to a decrease in chemical properties such as corrosion resistance and oxidation resistance. The castings may experience corrosion and oxidation problems in specific environments, seriously affecting their service life and reliability. Table 6 shows the impacts of poor microstructures on casting products.

| Impact Aspect | Specific Impact |

|–|–|

| Mechanical Properties | Lowers tensile strength, yield strength, hardness, etc. |

| Physical Properties | Reduces coefficient of thermal expansion, thermal conductivity, specific heat capacity, etc. |

| Chemical Properties | Decreases corrosion resistance and oxidation resistance |

Table 6: Impacts of Poor Microstructures on Casting Products

5.2.3 Impact of Original Defects Not Eliminated after Welding Repair

- Reduction in Mechanical Properties: Unremoved original defects during the welding process, such as non – fusion, cracks, and slag inclusions, can further reduce the mechanical properties of the castings. These defects can reduce the effective load – bearing area of the weld and intensify stress concentration, making the castings prone to fracture or plastic deformation under load.

- Impaired Sealing Performance: For castings that require sealing, such as pressure vessels and pipes, unremoved pores and lack of fusion after welding repair can lead to leakage accidents inside or outside the equipment.

- Reduction in Corrosion Resistance and Shortening of Fatigue Life: The metal structure at the original defect site is usually different from that of the normal weld, making it more susceptible to the action of corrosive media and accelerating the corrosion rate of the castings. In addition, these defects are also the initiation sites of fatigue cracks, which can shorten the fatigue life of the castings. Under alternating loads, the stress concentration at the defect site can accelerate crack propagation, eventually leading to fatigue fracture of the castings. The impacts of original defects not eliminated after welding repair are shown in Table 7.

| Impact Aspect | Specific Impact |

|–|–|

| Mechanical Properties | Lowers mechanical properties due to reduced effective load – bearing area and increased stress concentration |

| Sealing Performance | Causes leakage accidents in pressure – bearing components |

| Corrosion Resistance and Fatigue Life | Reduces corrosion resistance and shortens fatigue life |

Table 7: Impacts of Original Defects Not Eliminated after Welding Repair on Casting Products

5.2.4 Impact of Defects Caused by Poor Machining

- Reduction in Mechanical Properties: Poor machining may cause defects such as cracks, scratches, and pits on the surface or inside of the casting products. These defects can break the continuity of the material and reduce the mechanical properties of the products, such as tensile strength and yield strength. In high – stress or high – load components, these defects may lead to product fracture or failure during use.

- Reduction in Dimensional Accuracy: It may also cause the dimensional accuracy of the casting products to exceed the allowable tolerance range, affecting the assembly and service performance of the products. Table 8 shows the impacts of defects caused by poor machining on casting products.

| Impact Aspect | Specific Impact |

|–|–|

| Mechanical Properties | Lowers tensile strength, yield strength, etc. due to material discontinuity |

| Dimensional Accuracy | Affects product assembly and service performance due to dimensional deviation |

Table 8: Impacts of Defects Caused by Poor Machining on Casting Products

6. Preventive Measures for Defects

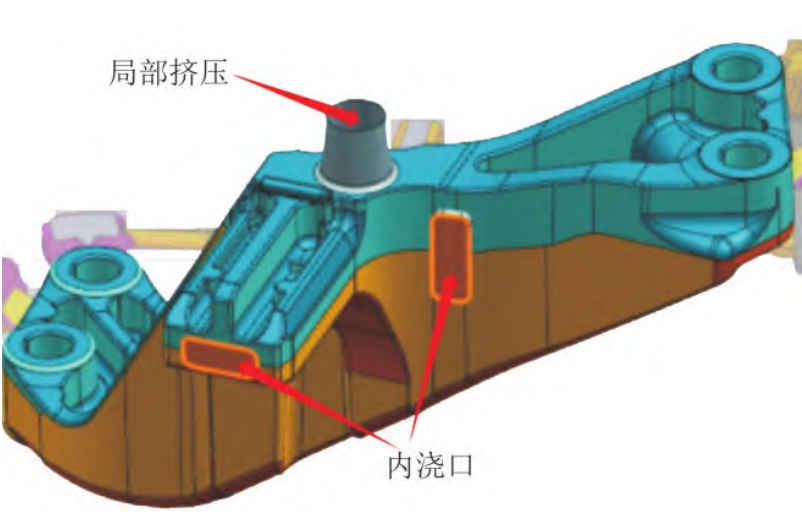

6.1 Optimization of Casting Process

- Improve Molding Technology: Adopt advanced molding methods such as precision casting and lost – foam casting to reduce the occurrence of casting defects. These methods can improve the dimensional accuracy and surface quality of the castings and reduce the formation of pores, shrinkage porosity, and cold shuts.

- Control Pouring Parameters: Reasonably control pouring temperature, pouring speed, and pouring volume to ensure the smooth filling of the mold and the proper solidification of the molten metal. Improper pouring parameters can lead to defects such as cold shuts and porosity.

6.2 Strict Material Selection and Quality Control

- Select High – Quality Materials: Choose casting materials with stable quality and good performance. For example, when selecting cast steel materials, ensure that they meet the requirements of strength, toughness, and purity.

- Strengthen Material Inspection: Conduct strict inspections on incoming materials, including chemical composition analysis, mechanical property testing, and non – destructive testing, to prevent defective materials from entering the production process.

6.3 Rational Design of Heat Treatment Process

- Formulate Appropriate Heat Treatment Parameters: According to the material type and product requirements, design a reasonable heat treatment process to improve the microstructure and mechanical properties of the castings. For example, for aluminum alloy castings, an appropriate solution treatment and aging treatment can improve their strength and hardness.

- Control Heat Treatment Process: Strictly control the heating rate, holding time, and cooling rate during the heat treatment process to ensure the quality of the heat – treated products.

6.4 Establishment of a Sound Defect Prevention and Repair Mechanism

- Implement In – Process Inspection: Set up multiple inspection points during the manufacturing process, including raw material inspection, semi – finished product inspection, and final product inspection. Use non – destructive testing methods such as ultrasonic testing, magnetic particle testing, and radiographic testing to detect defects in a timely manner.

- Develop Scientific Repair Procedures: For castings with defects, develop scientific and reasonable repair procedures. When welding repair is carried out, strictly control welding parameters, pre – heat and post – heat treatment to ensure that the repaired area has good mechanical properties and meets quality requirements.

7. Conclusion

The manufacturing process defects of casting products for motor train units are complex and diverse, which have a significant impact on the performance, safety, and reliability of motor train units. Through in – depth case analysis and defect research, it is clear that original casting defects, poor microstructures, original defects not eliminated after welding repair, and defects caused by poor machining are the main types of defects. These defects can affect the structural integrity, appearance quality, service performance, and other aspects of casting products.

To address these issues, a series of preventive measures should be taken, such as optimizing the casting process, strictly selecting materials and controlling quality, rationally designing the heat treatment process, and establishing a sound defect prevention and repair mechanism. By implementing these measures, the occurrence probability of casting defects can be effectively reduced, and the quality and performance of casting products can be improved.

In addition, casting enterprises should pay close attention to industry trends and technological developments, continuously introduce new technologies and new processes, and carry out innovation in manufacturing processes. This can help enterprises to better meet the market demand for high – quality casting products for motor train units and promote the healthy development of the rail transit industry.